- How to Select a Four-Girder Casting Loading Crane: Precise Matching for High-Temperature, Heavy-Load Scenarios

-

Release Time:2025-08-21 15:37:22Share:

How to Select a Four-Girder Casting Loading Crane: Precise Matching for High-Temperature, Heavy-Load Scenarios

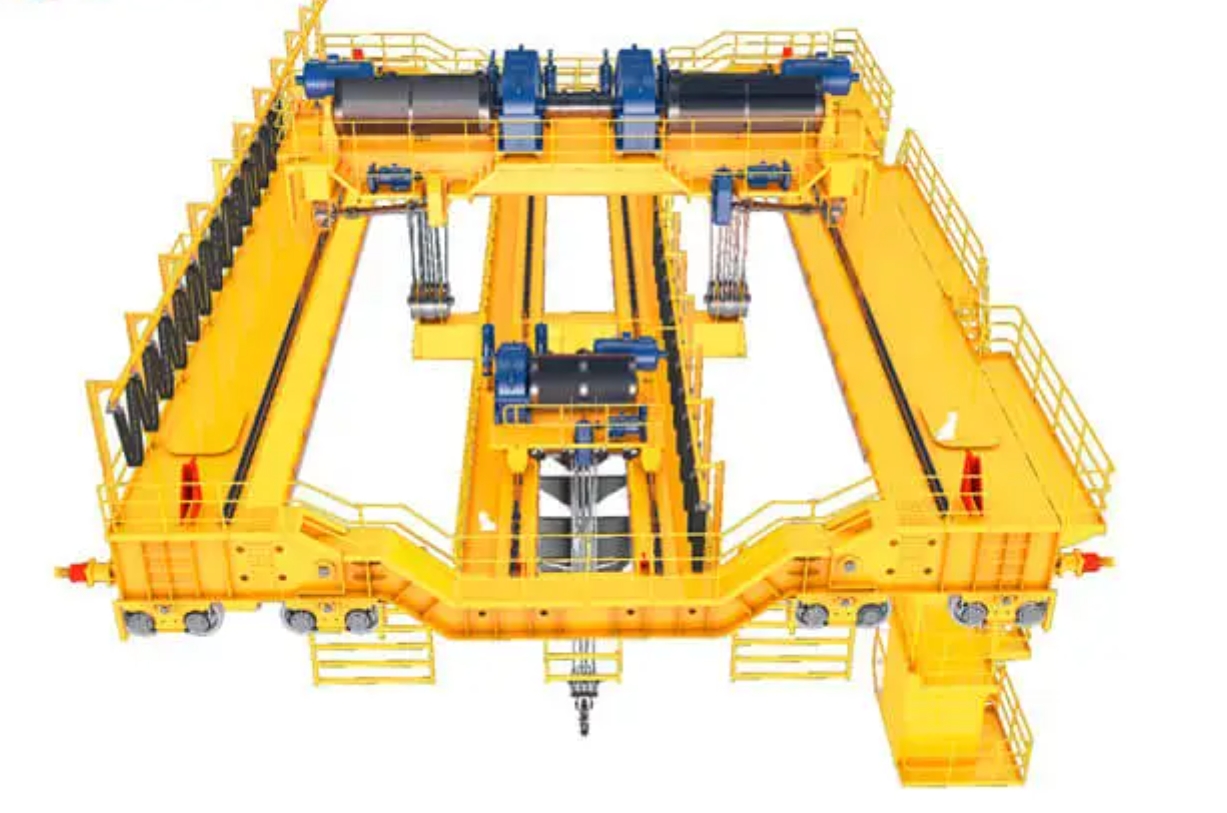

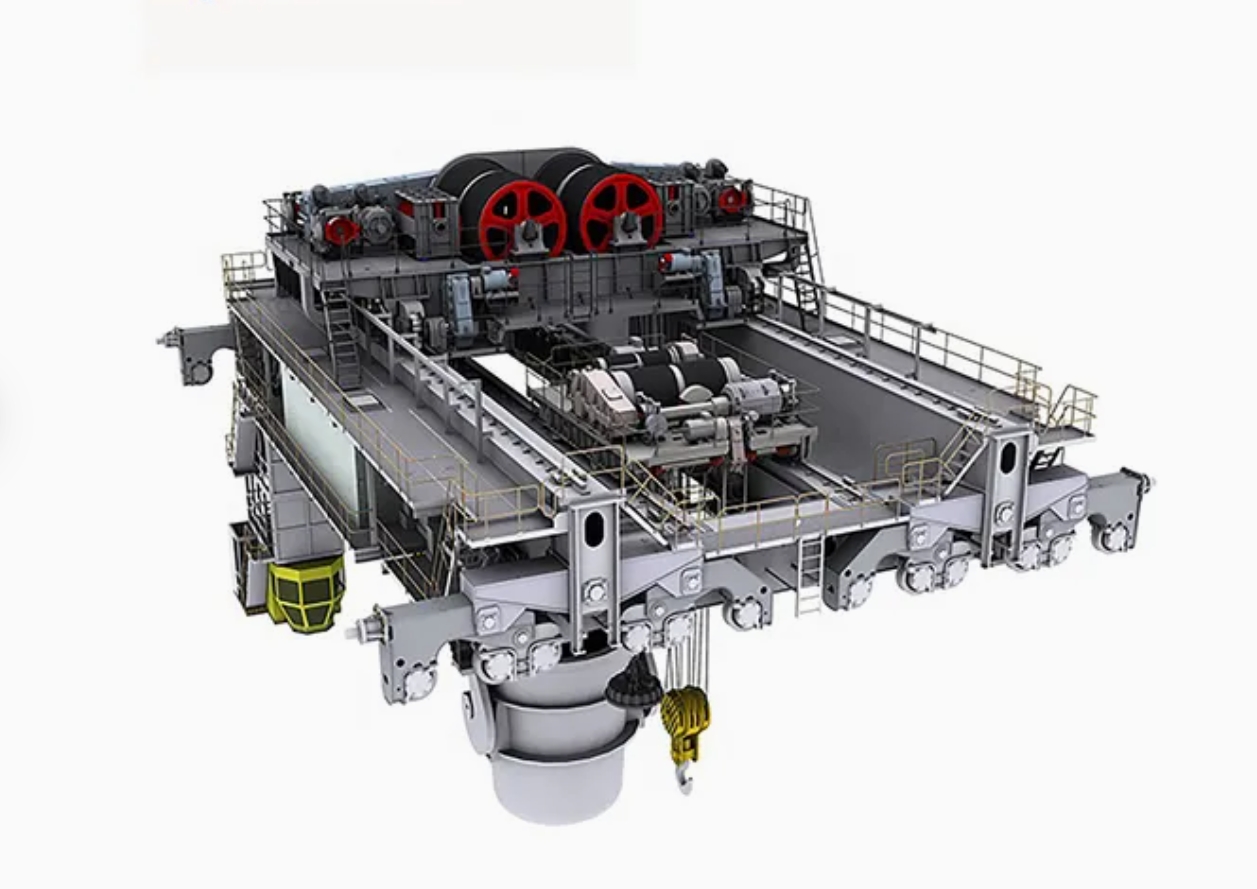

In high-temperature, heavy-load work scenarios in industries such as steel and casting, the four-girder casting loading crane, with its unique four-girder, four-track structure, ultra-strong load-bearing capacity, and stable operating performance, has become the core equipment for lifting and transporting molten metal containers such as steel ladles and iron ladles. The selection of such equipment directly impacts production safety and efficiency. Improper selection may lead to equipment failures or even safety incidents. Therefore, enterprises must conduct a systematic evaluation from dimensions such as operational scenarios, performance parameters, and safety configurations to ensure precise matching between the equipment and operational conditions.

Focusing on Core Operational Scenarios, Ensuring Structural Compatibility

The core value of the four-beam casting loading crane lies in its ability to handle extreme conditions such as “high temperature + heavy load + eccentric load.” Operational requirements vary significantly across industries, necessitating tailored structural designs.

Steel melting shop steel ladle handling: Enhanced impact resistance and thermal insulation capabilities

Steel melting shops frequently handle steel ladles exceeding 1,600°C, with individual ladles weighing up to 300 tons. The movement of molten steel can generate eccentric loads, imposing extremely high demands on the crane's structural strength and thermal insulation performance:

Four-beam structure selection: The main beams must be made of Q355ND low-temperature ductile steel, with a web thickness of no less than 30 mm, formed through integral welding to ensure no plastic deformation under vertical and horizontal loads. A four-track design (two tracks on each side) distributes wheel loads, reducing the load on the plant's steel structure, with wheel loads preferably controlled below 250 kN.

Thermal insulation protection system: The hook assembly and pulley assembly must be equipped with multi-layer composite thermal insulation covers (inner layer of aluminum silicate fiber + outer layer of high-temperature resistant steel plates) to block radiant heat from reaching the core components of the equipment, ensuring that the operating environment temperature of electrical components does not exceed 60°C. The hoisting mechanism motor and cables must use special high-temperature resistant models capable of withstanding 150°C to prevent insulation aging.

Impact-resistant design: The connection points between the trolley frame and main beam are fitted with buffer devices using high-elasticity polyurethane material, capable of absorbing 80% of instantaneous impact loads to withstand the swaying impacts during steel ladle lifting.

Iron water ladle transportation in foundry workshops: Emphasizing precise control and stability

Iron water ladles in foundry workshops typically weigh between 50 and 150 tons, with relatively slow operational rhythms but higher requirements for positioning accuracy (e.g., aligning with sand mold pouring ports). When selecting equipment, the following should be considered:

Micro-motion control performance: The hoisting mechanism is equipped with a low-speed ratio variable frequency system (1:100), enabling stepless speed adjustment from 0.5 to 5 m/min to ensure smooth operation during pouring and prevent molten iron splashes. The main and auxiliary crane running mechanisms use closed-loop control, with positioning error ≤ ±50 mm, meeting precise alignment requirements.

Dual trolley collaborative operation: Some large foundry workshops require dual trolley coordination (main trolley for lifting the iron water ladle, auxiliary trolley for cleaning). The four-beam structure enables independent operation of dual trolleys without interference, with speed differences between trolleys controlled within 5 m/min to prevent operational conflicts.

Dust protection upgrade: Foundry workshops have high dust levels, so electrical cabinets must be equipped with a positive pressure ventilation system to maintain internal pressure 50 Pa higher than the external environment, preventing dust intrusion. Motors and reducers use IP65 protection ratings, and bearing housings are fitted with labyrinth seals to extend equipment lifespan.

Focus on key performance parameters to avoid “over-performance” or “under-capacity”

The parameter selection for four-beam casting material handling cranes must strictly match actual load and operational intensity, avoiding both the wasteful pursuit of excessive tonnage and the safety risks posed by insufficient parameters.

Lifting capacity: Ensure adequate safety margin

The lifting capacity must cover the total of “steel ladle/iron ladle self-weight + maximum loading capacity + lifting device weight,” with an additional safety margin of over 20%:

For example, when lifting a 100-ton steel ladle (including molten steel), with a lifting device weight of approximately 10 tons, the total load is 110 tons. A crane with a rated lifting capacity of ≥132 tons should be selected to ensure safe operation even in case of sudden overload (e.g., excessive molten steel).

For double-girder crane models, the lifting capacity of the main and auxiliary gantries must be calculated separately. The main gantry's lifting capacity is calculated based on the main load, while the auxiliary gantry's lifting capacity is typically 1/5 to 1/3 of the main gantry's capacity (e.g., if the main gantry is 200 tons, the auxiliary gantry is 50 tons), to meet auxiliary operation requirements.

Work level: Matching operational frequency and intensity

Select the work level based on the daily operational cycle count (one cycle consists of lifting + running + lowering). Four-beam casting loading cranes must meet A7 or higher:

Steel mill (daily cycles ≥120): Select A8 level, with hoisting mechanism motors using H-class insulation, and brake wear compensation devices ensuring 100,000 brake cycles without failure, suitable for high-intensity continuous operations.

Casting shop (daily cycles 50–100): A7 level is sufficient to meet requirements, balancing durability with reduced procurement costs.

Lifting height and span: Adapted to the factory layout

Lifting height: Must meet the vertical distance from the ground to the highest position of the lifting device. When lifting a steel ladle, the lifting height should be ≥12m (including the steel ladle's own height of 3-5m) to ensure it can span equipment such as steel furnaces and continuous casting machines.

Span: Determined based on the track spacing in the factory, typically 10-30m, When the span exceeds 20m, the main beam must adopt a variable cross-section design to reduce self-weight by 15% while maintaining strength, thereby reducing pressure on the tracks.

Safety Configuration: Building a “Zero-Tolerance” Protection System

The safety configuration of the four-beam casting loading crane directly impacts personnel and equipment safety and must comply with national “Safety Regulations for Cranes” and industry-specific standards:

Multiple Braking and Limit Protection

The hoisting mechanism adopts a “dual brake + dual reducer” redundant design. If one brake fails, the other can emergency brake within 0.5 seconds, with a braking safety factor ≥1.75.

Equipped with a hoisting height limiter (to prevent the hook from hitting the top), a main/auxiliary crane travel limiter (to avoid colliding with the factory building), and a boom angle limit switch (for models with boom angle adjustment functionality). All limit switches have a two-stage function of “alarm + shutdown.”

Intelligent Monitoring and Warning System

Load sensors and swing angle monitors are installed to display the load weight and swing angle in real time. When the load exceeds 10% of the rated capacity or the swing angle exceeds 3°, the system automatically alarms and cuts off the hoisting power.

Temperature and vibration sensors are installed on critical components (such as brakes and bearings). Through the industrial internet platform, equipment status is remotely monitored. When temperature exceeds 80°C or vibration is abnormal, early warnings are issued to prevent sudden failures.

Emergency Backup Functionality

Equipped with a 30-minute backup power supply, in case of sudden power outage, heavy loads can be slowly lowered to the ground, preventing dangerous situations caused by suspended steel ladles.

Emergency stop buttons are installed in both the operator cab and ground control station, with a response time of ≤0.1 seconds, ensuring immediate shutdown in case of emergencies.

Henan Mining: Customization Experts for Four-Girder Casting Loading Cranes

Selecting the appropriate four-girder casting loading crane is a systematic process balancing safety, efficiency, and cost, and standardized equipment may not fully accommodate complex operating conditions. Henan Mining has specialized in the metallurgical crane field for over 20 years and can provide full-process customized services based on the specific needs of enterprises:

Customized structural design: For the scenario of lifting a 300-ton ultra-large steel ladle, a four-beam, four-track, dual-trolley structure is customized. The main beam is inspected using German-imported non-destructive testing equipment, and all critical welds undergo 100% UT testing to ensure zero defects in the structure.

Safety performance upgrades: All models have passed national A8-level type testing. The hoisting mechanism braking system uses German SEW motors and Siemens variable frequency systems, combined with our independently developed intelligent monitoring platform, to achieve “warning - protection - traceability” full-chain safety management.

Full lifecycle service: Free on-site surveys and operational condition simulations are provided. After installation, quarterly on-site inspections are conducted for thermal insulation layer checks, brake system calibration, and other specialized maintenance to ensure long-term stable operation of the equipment in high-temperature, heavy-load environments.

Choosing a four-beam casting material handling crane is essentially about building a robust safety barrier for high-temperature, heavy-load operational scenarios. Henan Mining focuses on technological innovation, using customized solutions to help steel and casting companies improve production efficiency and reduce safety risks, becoming an indispensable reliable partner in industrial production. If you wish to obtain a customized selection plan, please contact our technical team, and let our expertise safeguard your production safety.