Single Girder Gantry Kran

Single Girder Gantry Kran

Effizient. Zouverlässegkeet. Kosteneffektiv Lifting fir industriell Ëmfeld.

Den Henan Mine Single Beader Gantry Crane ass entwéckelt fir flexibel Hebeleistung ze liwweren ouni sech op existent Gebaiestrukturen ze vertrauen. Entworf fir souwuel Indoor wéi och Outdoor Ëmfeld, ass et déi ideal Léisung fir Frachthafen, Lager, Fabriken an oppen Lagerbereicher.

Mat senger rationaliséierter Struktur, héichstärkege Materialien an engem kompakten elektresche Lift bitt dëse Kran e glatte, stabile an effiziente Betrib. Gebaut an voller Konformitéit mat GB / T 3811-2008 an JB / T 5663-2008 Standarden, garantéiert et Sécherheet, Haltbarkeet a Leeschtung iwwer all industriell Lifting Szenarien.

| Feature | Spezifikatioun |

| Marke | Henan Mine |

| Modell | Single Girder Gantry Kran |

| Liftkapazitéit | 1 32 Tonnen |

| Spann Längt | 4 35 Meter |

| Lifting Héicht | 6m / 9m / 12m (customizable) |

| Aarbechtspflicht | A3, A4, A5 |

| Spannungsbereich | 220V690V, 3-Phas, 5060Hz |

| Ëmfeldtemperatur | -25°C to +45°C, ≤85% humidity |

| Kontrollmodus | Anhänger / Fernbedienung / Kabine |

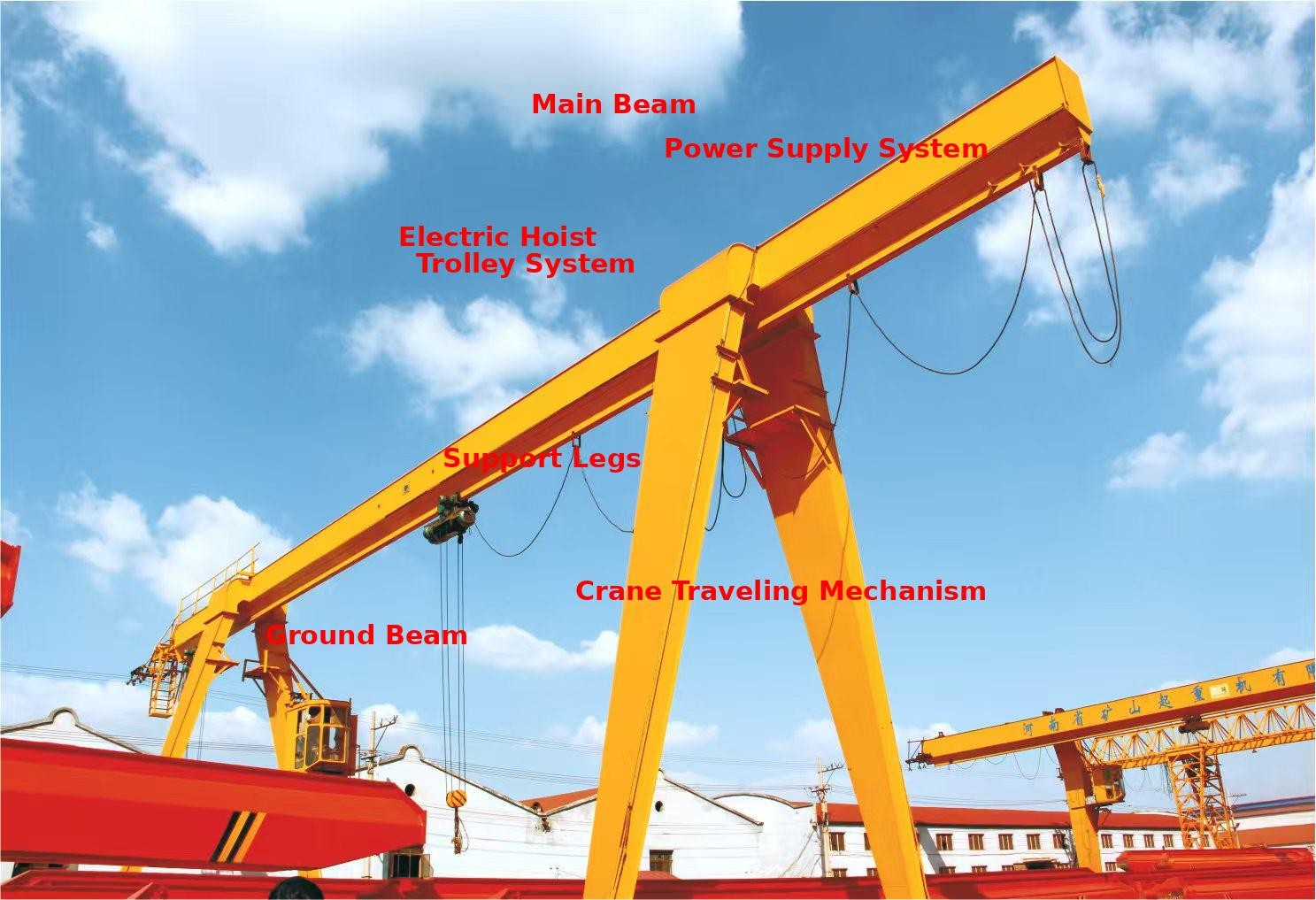

D'Haaptkomponenten op e Bléck

| Komponent | Beschreiwung |

| Haaptstrahl | Dräieckstruktur aus I-Beam an Stolrahmen geschwäisst, Bogen-Cambered fir besser Belaaschtungsënnerstëtzung. Enthält Puffer fir de Schutz vum Trolley. |

| Ground Beam (Ground Beam) | Box Beam Struktur aus Flanschplätzen, Weben a Steifer geschwäisst; garantéiert lateral Stabilitéit a glat Schienenmontage. |

| Ënnerstëtzung Been | A-Frame Konfiguratioun mat Boltflanschverbindungen, déi steif Ënnerstëtzung a einfach Transport oder Montage ubidden. |

| Elektresch Hoist | Hoist includes painted shell, overload protection, dual-lifting speeds (CD/MD), and precise load handling. |

| Reesmechanismus | Separate drive motor, brake, and reducer with compact vertical gearbox; anti-derailment wheels (LDA-type). |

| Elektresch System | Optiounen fir Flachkabel, C-Track oder Busbar; ausgestatt mat Schneider-Grad Schaltbrecher an Interlocks. |

| Kontrollsystem | Wielt aus Pendant-, Fern- oder Kabinenbaséiert Systemer mat voller Sécherheetsredundanz. |

| Schutzapparater | Enthält Iwwerbelastung Limiter, Rees Limiter, Phase Feeler Schutz, Feier Limit, an Lift Héicht Limit. |

Füllt de Formulaire hei ënnen aus fir direkt Zougang zum Krankatalog ze kréien an schwätzt mat eisem technesche Team fir Rekommendatiounen