Insuleerde Voerder Oorkant Kran vir Elektrolytiese Aluminium

Insuleerde Voerder Oorkant Kran vir Elektrolytiese Aluminium

Engineer deur Henan Min – Seker, Presisie en gebou vir Harsh Environments

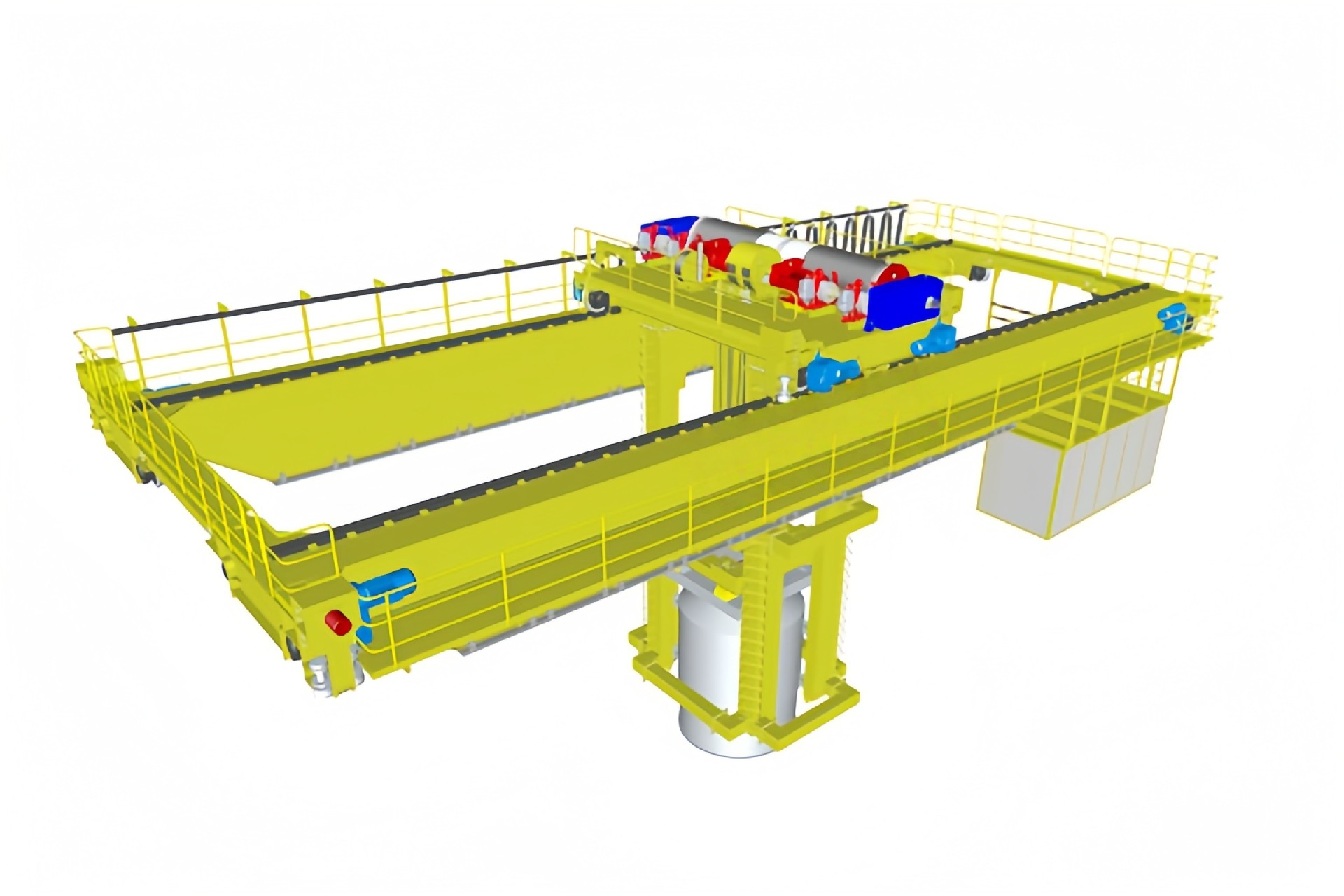

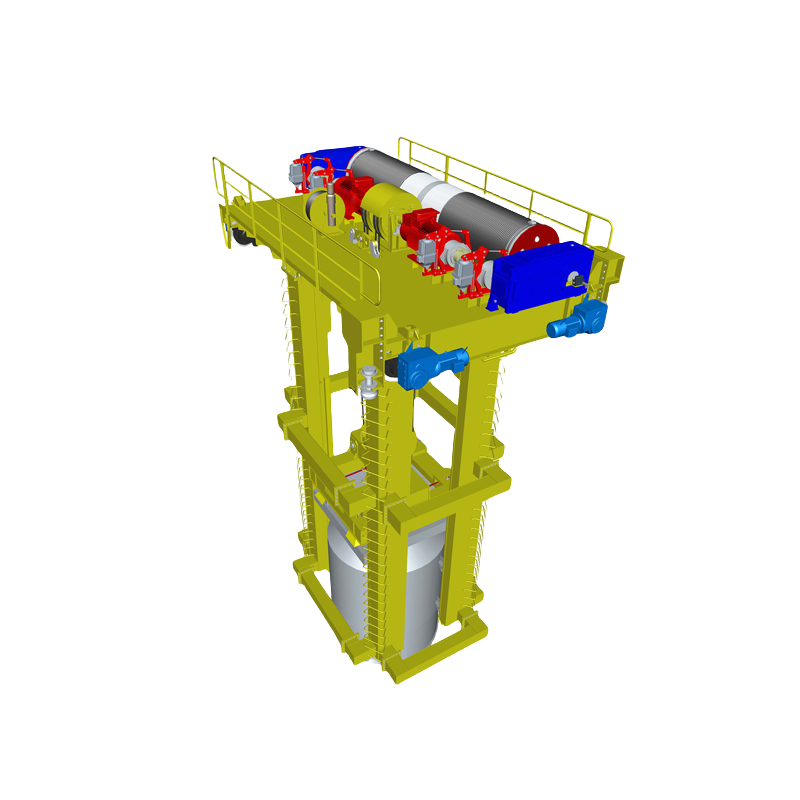

Die Henan myne Insuleerde Voerder Oorkant Crane is 'n gevorderde oorvloediging stelsel, spesifieke ontwikkeld vir die elektrolitiese aluminum industrie, waar ekstreme operasie voorwaardes--soos hoë temperatuur gegote soet, swaar huidige, sterk magnetiese velde en korosiewe atmosfere--vra baie spesialiseerde oplossing.

Hierdie krane kombinieer hoë-voltaaie insulaasie-teknologie, anti-magnetiese ontwerp en 'n bespesifiseerde feeding trolley om sleutel produksie-taak te doen insluitend aluminum fluoride-voedsel, gegote aluminum-uittrekking, sel-struktuur-handling en meer. Vertroud deur boonste aluminum-produseerdes, speel dit 'n sentrale rol in die verseker van voortdurende, veilige en automatiseerde operasies binne smeltingsplante.

| Gewaarde Ligging Kapasiteit | Custom-configured (typically 10–74 tons) |

| Crane Opstelling | Drie- beam, drie- trolley uitleg |

| Spesiale Trolleys | Tool Trolley (hook-type lifting);Aluminum Extraction Trolley (with insulated, anti-sway hook & weighing system);Feeding Trolley (with hopper, discharge system & electronic measuring unit) |

| Reise Mekanisme | 8-wiel, dubbel-dryf met skaft-gekoppel 3-in-1 reduseerders |

| Kontrole Modus | Cabin control + remote diagnostics |

| Omgewing | Anti-corrosion materials + sealed electronics |

| Operator KabinComment | Gekoppel met industriese HVAC vir ekstrem temperatuur voorwaardes |

| Sekerheitsstandaarde | GB, ISO, CE- compliant |

Opvul in die vorm onder om onmiddelik toegang te kry na die krane katalog en praat met ons tegniese span vir herkommunikasie