Aluminium Coil Elektriese Oordrag Kaart Stelsel

Aluminium Coil Elektriese Oordrag Kaart Stelsel

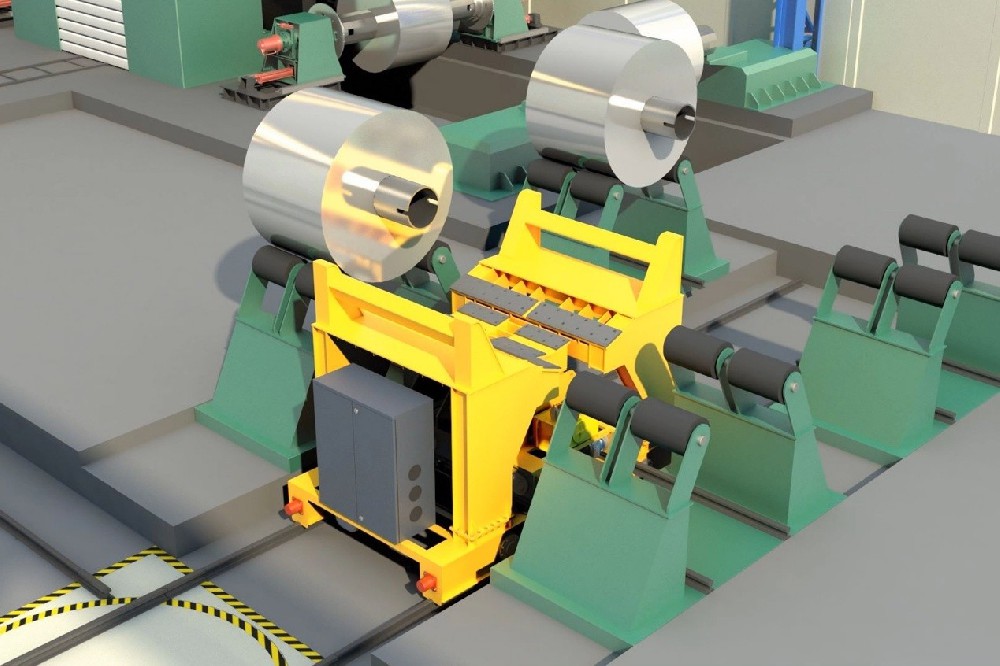

Precision Transport for Coil Handling – Engineer deur Henan Mine

Die Aluminum Coil Elektriese Oordrag Kaart Stelsel van Henan Mine nbsp; is 'n volledig integreerde koel-vervoeringsoplossing ontwerp om die spesifieke behoeftes van aluminum-verwerking plante en rol-mile te meet. Bygebou na streamliseer koel beweging, reduseer handling rizikes en verbeter produksievloei, hierdie stelsel speel 'n sleutel rol in modernisering van aluminum koel logistike.

Om 'n ouer-kinder kaart konfigurasie te funksioneer, hierdie stelsel verseker veilig, presies en outomatiese vervoer van voltooide aluminum koele tussen produksie lyne, buffer opslaan area en stuur sones. Of dit in 'n nuwe outomatiese fasiliteit geïnstalleer of in 'n bestaande werkskerm teruggestel is, laat dit op elke stadium operatiewe voortdurigheid en materiaal beskerming bevat.

| Stelsel Opstelling: | Mounted on rails, with saddle + conveyor system;Child Cart |

| Ligging Kapasiteit | 5 – 60 tons (customizable per coil weight and dimensions) |

| Reis Spoed | Up to 60 m/min (adjustable via frequency inverter) |

| Posisie Naakiteit | ±2 mm met sensor-gebaseerde lyn |

| Snit Tipe | Gebruik staal traal of oordruk- gids lyn |

| Uitvee Tipe | Electric motor + gear reducer with soft-start control |

| Krag verskaf | Cable drum / low-voltage rail / battery (site-dependent) |

| Sekerheidsstelsels | Stapel opdekking, oorlaai beskerming, nugtige stop |

| Compliance | ISO, GB, CE- sertifiseerde komponente |

Opvul in die vorm onder om onmiddelik toegang te kry na die krane katalog en praat met ons tegniese span vir herkommunikasie