Name

Name

High-Temperature Lifting Solutions for Electric Arc Furnace (EAF) Charging

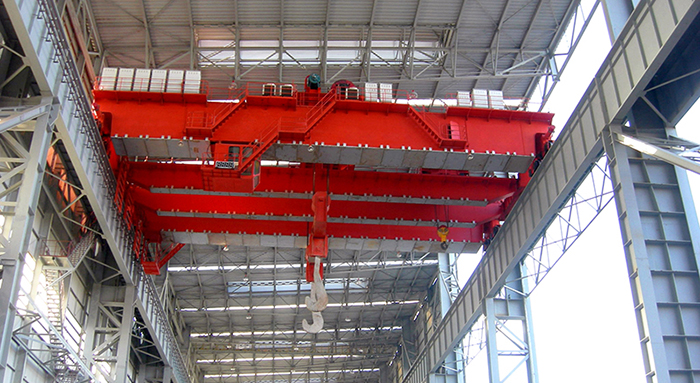

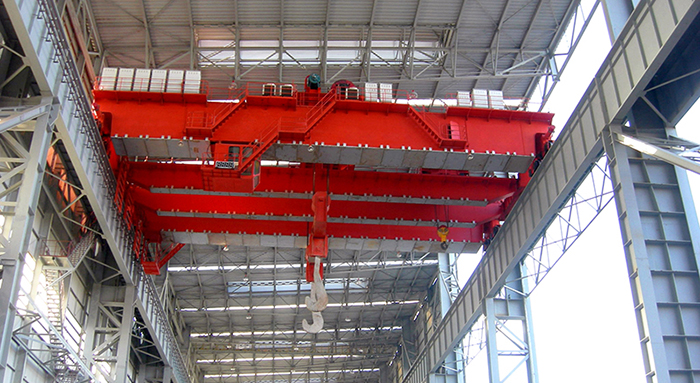

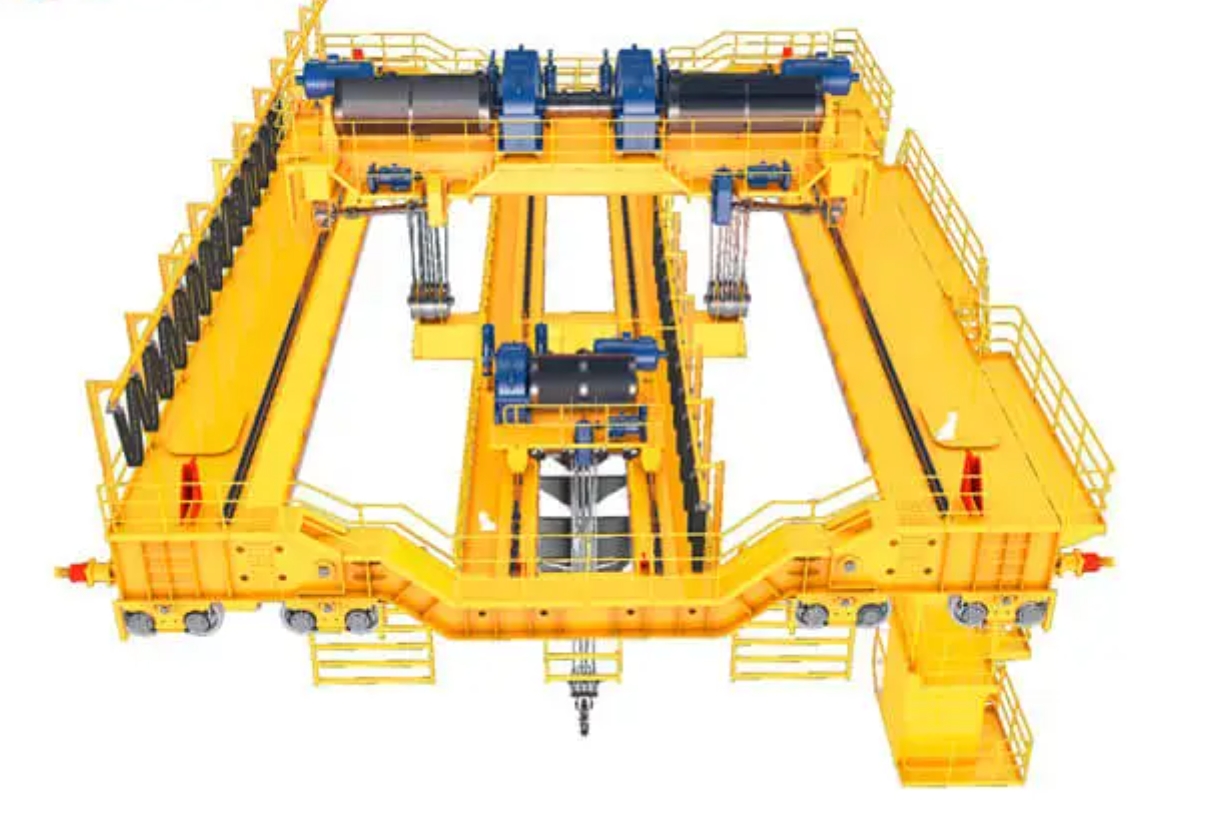

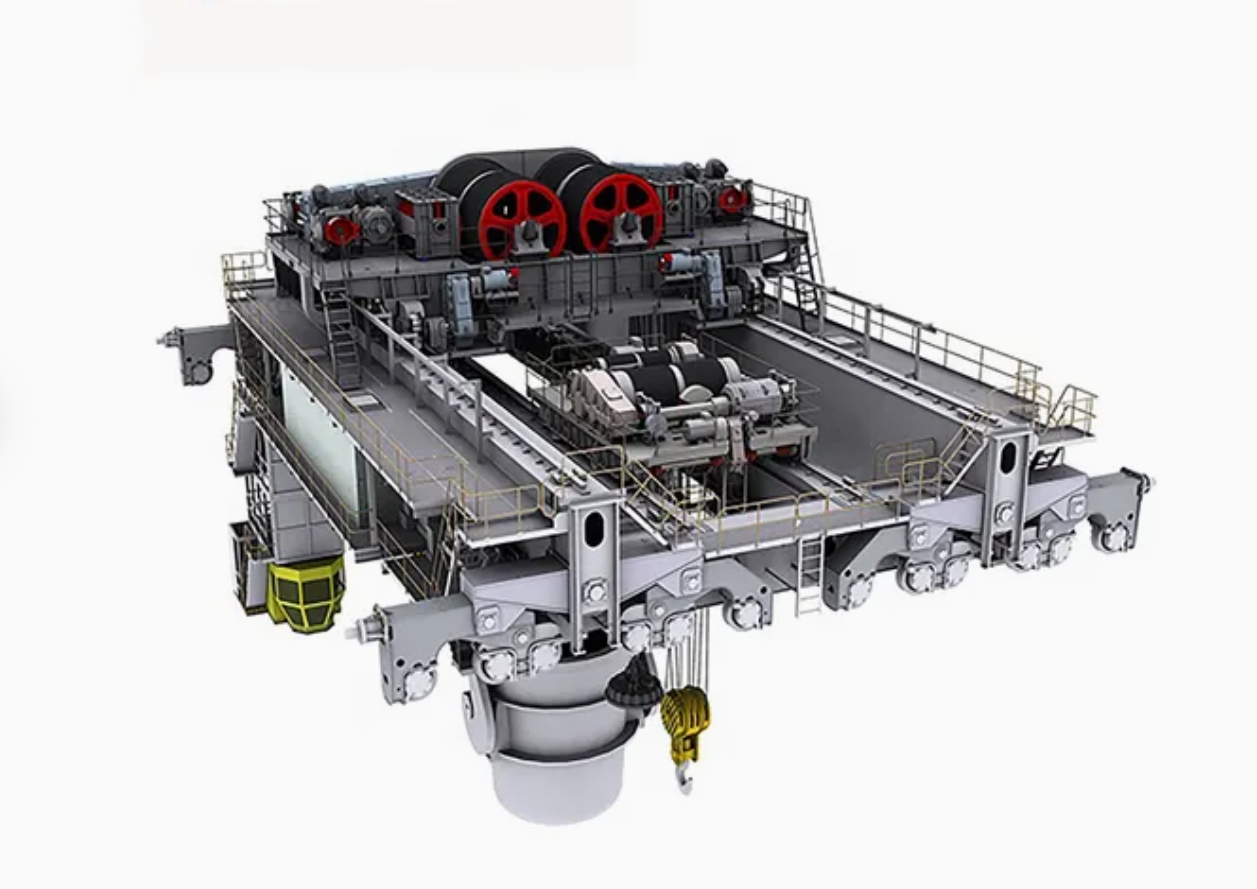

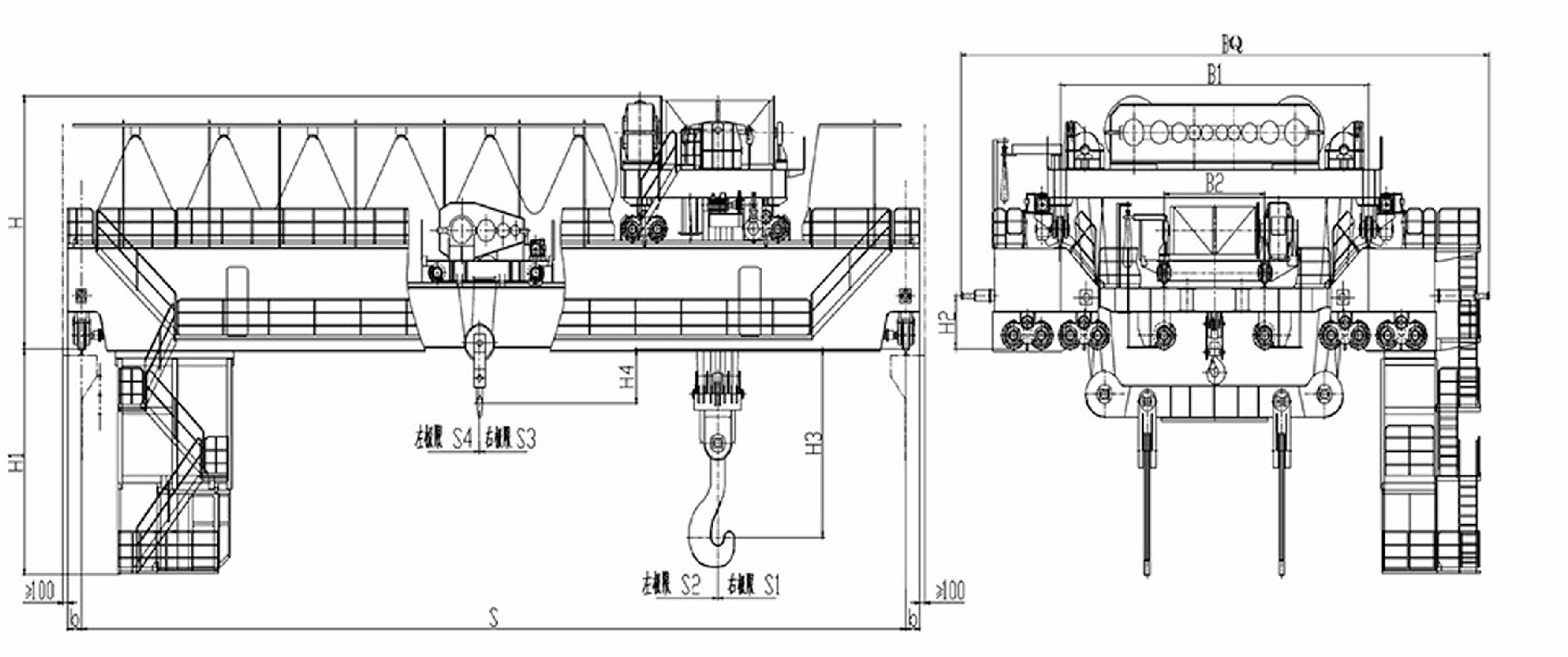

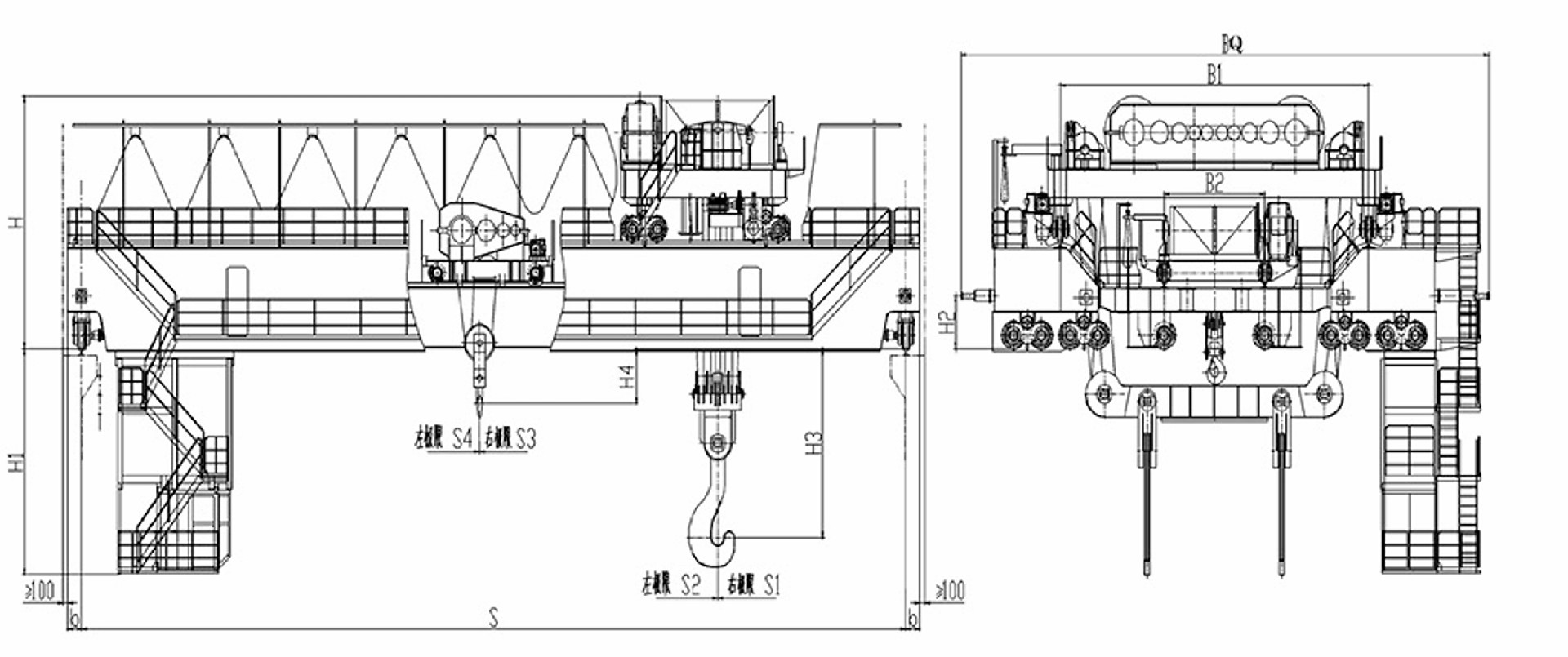

Henan Mine’s charging crane is a core component in steelmaking facilities, purpose-built for feeding electric arc furnaces (EAF) with scrap or molten metal. Designed for continuous operation under extreme heat, this overhead crane is also capable of delivering hot metal to the ladle furnace (LF) or continuous casting machine (CCM). Engineered with a four-girder configuration, it provides exceptional stability, lifting accuracy, and long service life.

In baie plante bedien hierdie krane ook as 'n rugsteun om krane te laai, en die produksiekontinuiteit in kritiese scenarios te verseker.

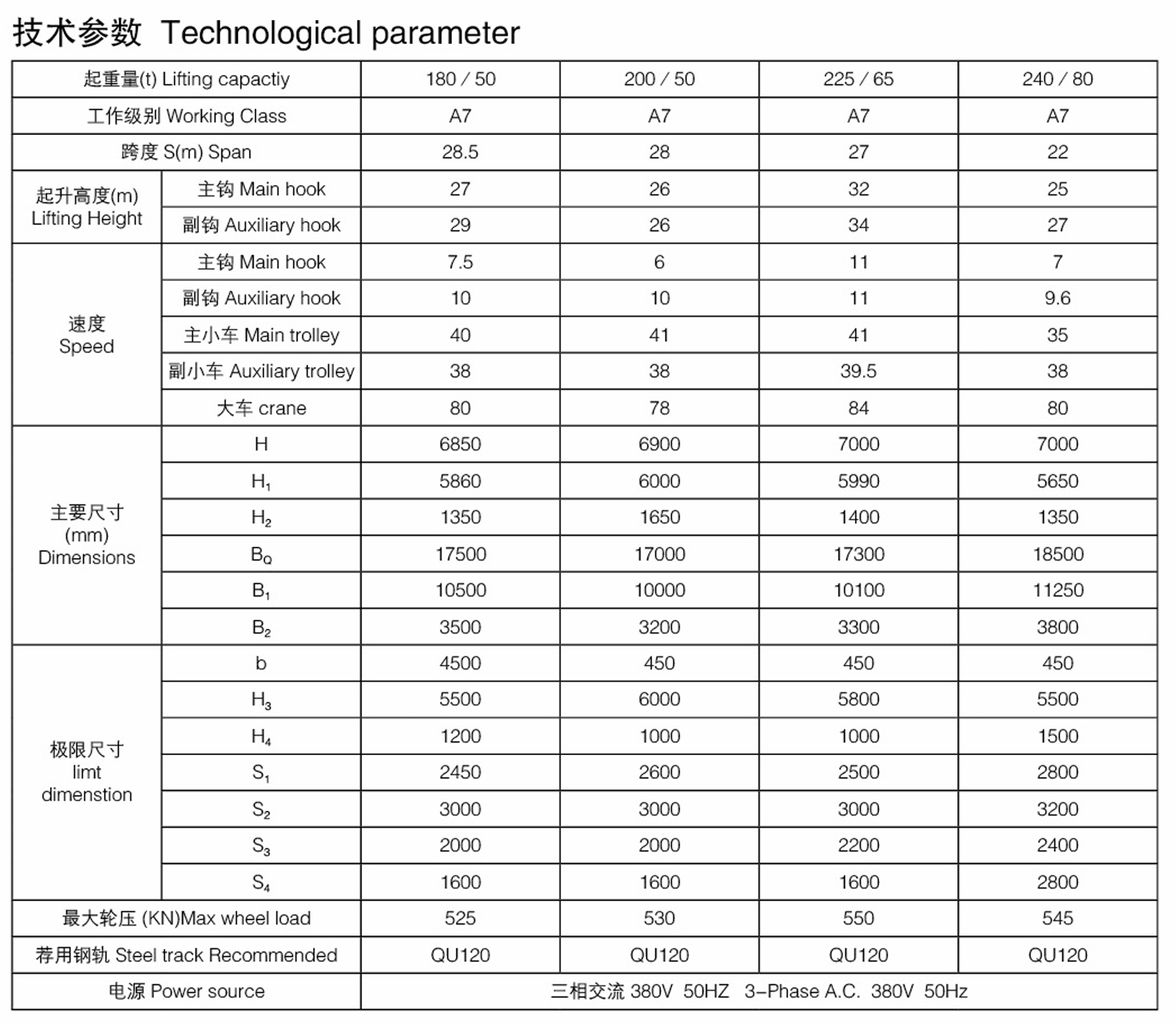

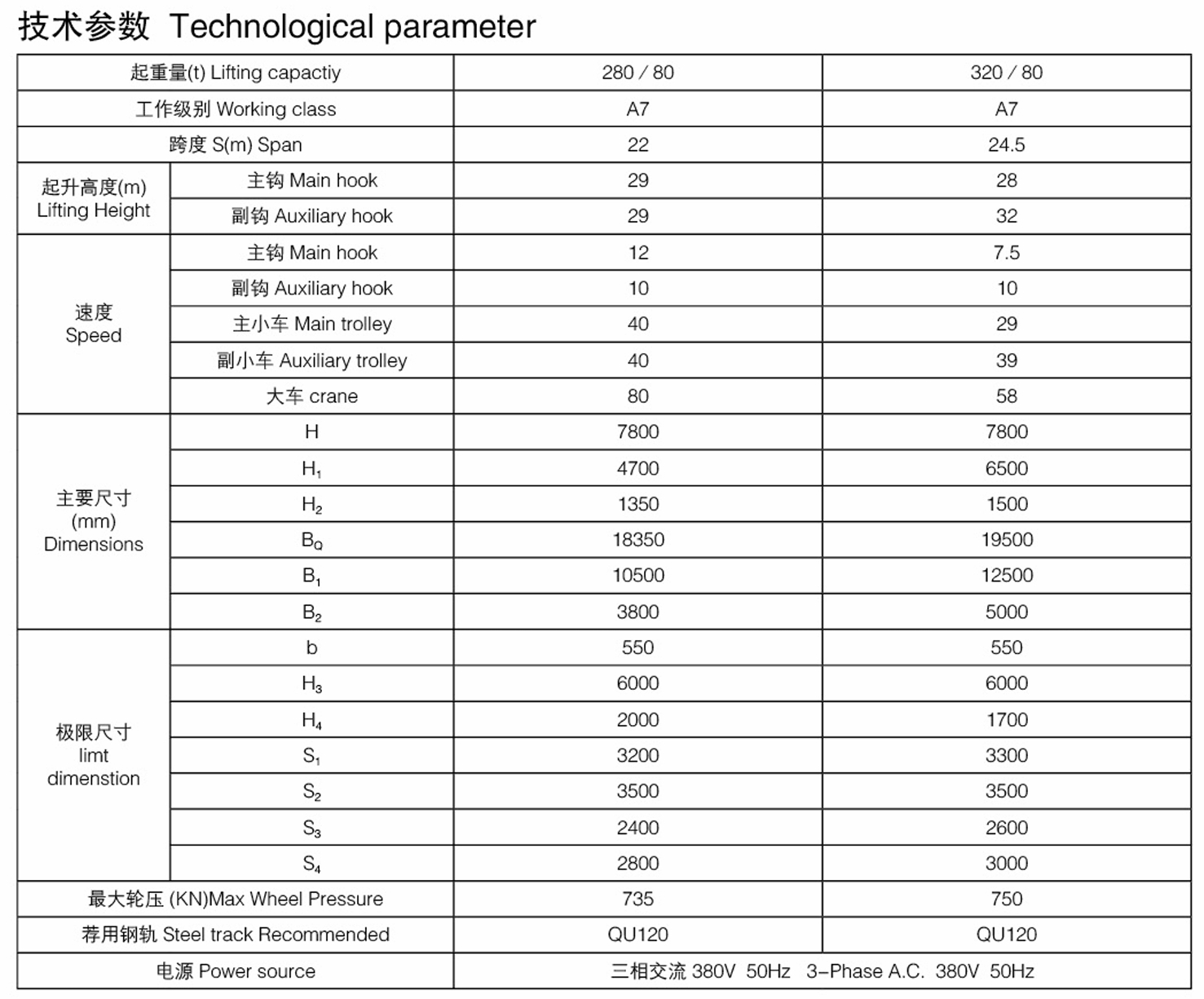

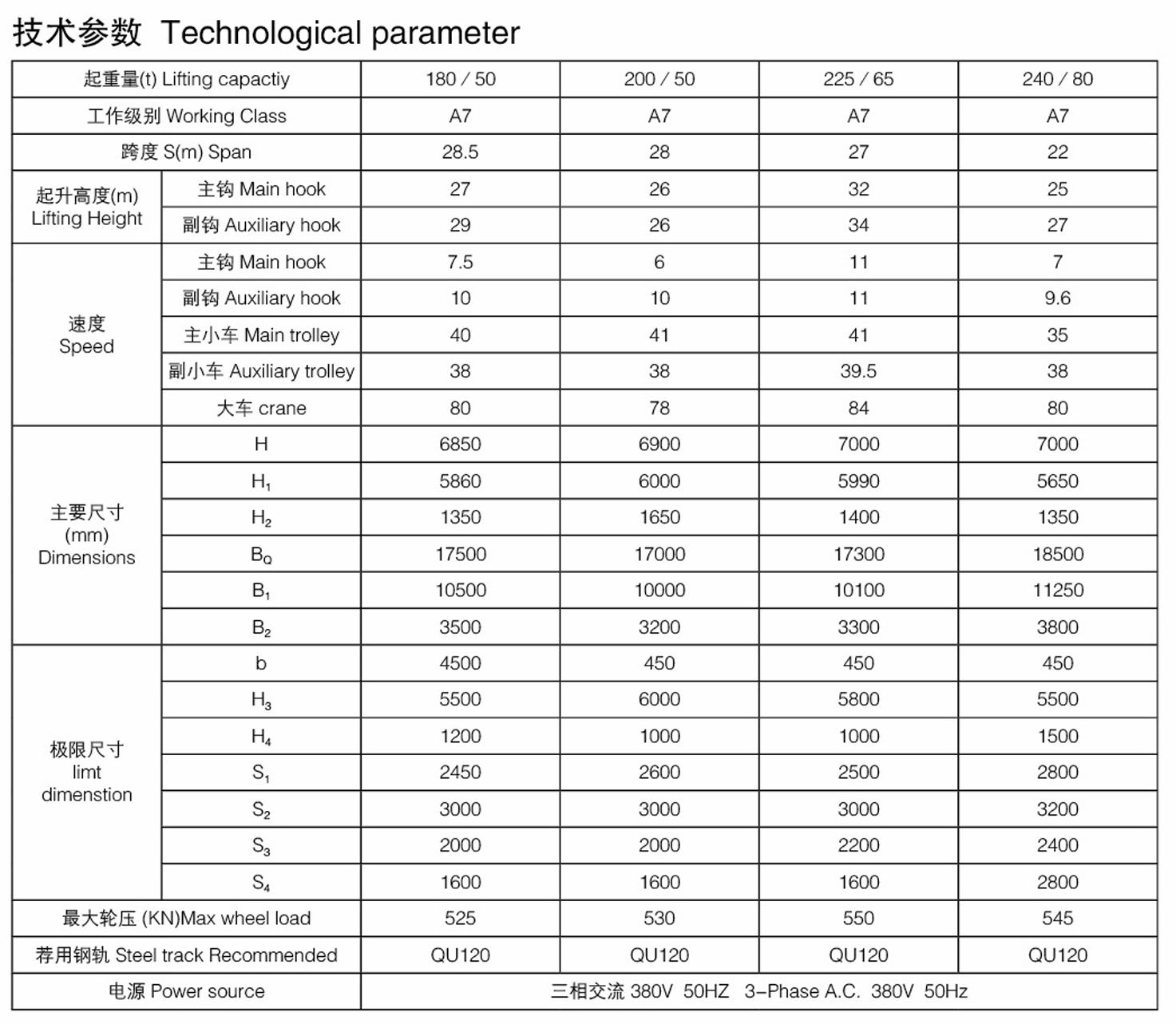

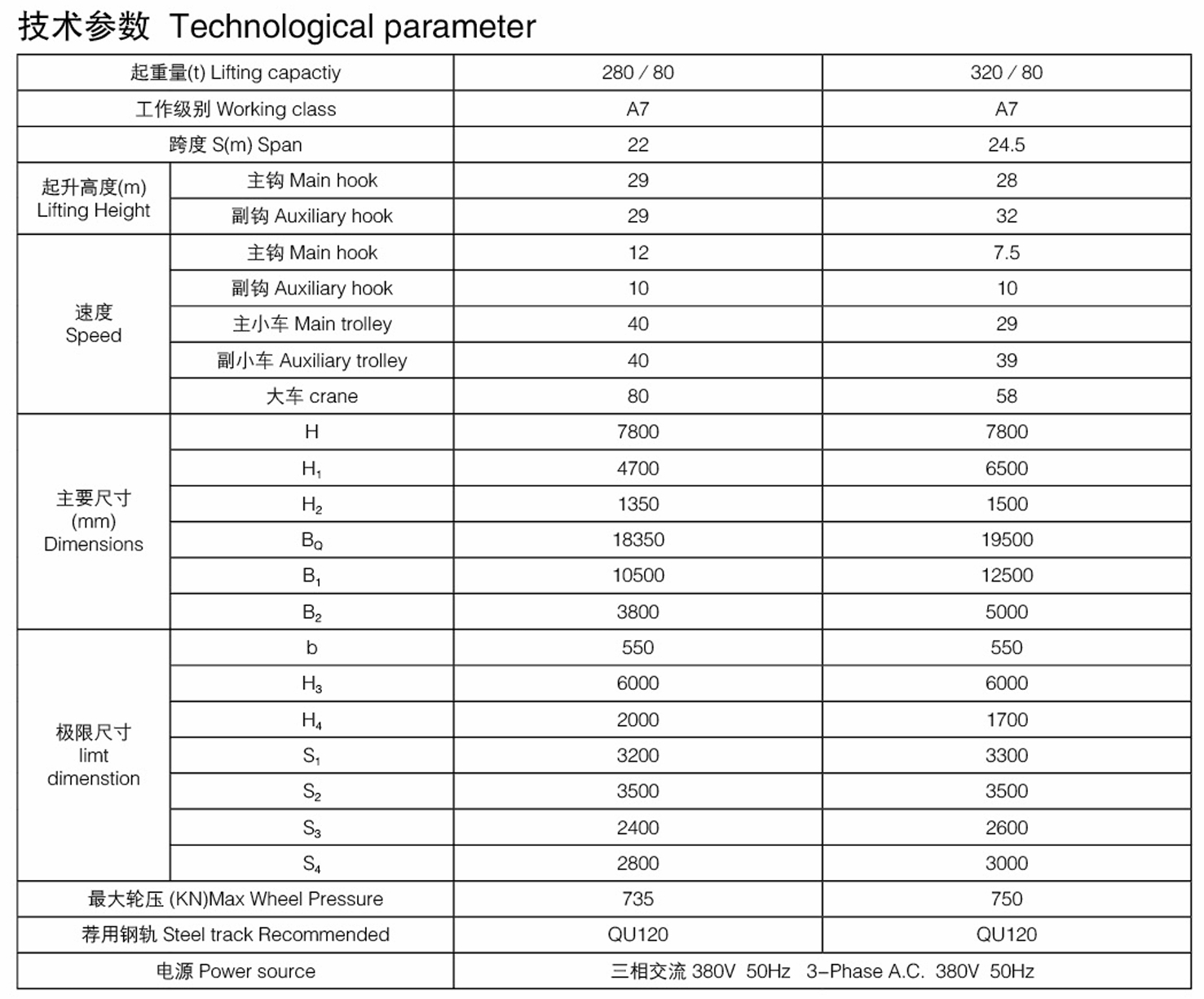

| Parameter | Waarde / Omvang |

| Crane Tipe | Name |

| Struktuur Ontwerp | Name |

| Ligging Kapasiteit | Up to 500 tons (customized) |

| Ligging Mekanisme | Dual-trolley met sinkroniseerde dryf |

| Aansoek Omgewing | Hoë warm, gegote metal, 24/7 opdrag |

| Herstel Beskerming | Thermal insulation, vlam skildering |

| Krag verskaf | 3- fase AC, pasmaak voltaak |

| Kontrole Stelsel | Cabin + Optional Remote |

| Redundancy | Rugsteun breek, tweede drywers, grenseerders |

| Sertifikaat | GB / ISO / CE- compliant |

Opvul in die vorm onder om onmiddelik toegang te kry na die krane katalog en praat met ons tegniese span vir herkommunikasie