Aluminium Coil elektrisk overførsel kurv System

Aluminium Coil elektrisk overførsel kurv System

Præcis transport til spolehåndtering Konstrueret af Henan Mine

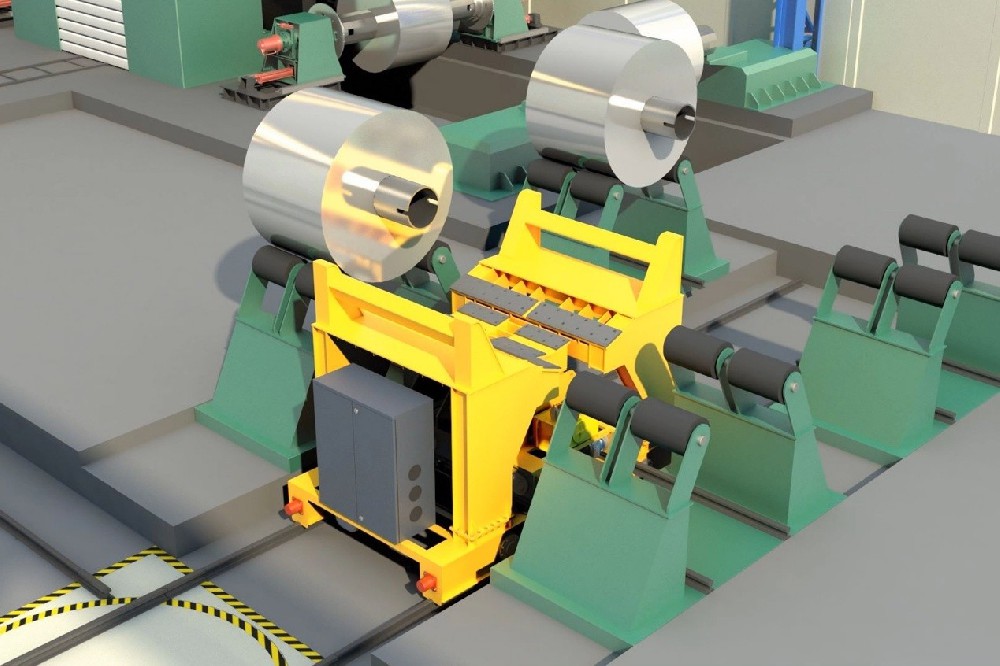

Aluminium Coil Electric Transfer Cart System & nbsp; fra Henan Mine er en fuldt integreret spoletransportløsning designet til at imødekomme de specifikke behov hos aluminiumforarbejdningsanlæg og valseværker. Dette system er bygget til at strømline spolebevægelsen, reducere håndteringsrisici og forbedre produktionsstrømmen, og spiller en nøglerolle i moderniseringen af aluminiumspolelogistikken.

Med en forældre-barn vognkonfiguration sikrer dette system sikker, præcis og automatiseret transport af færdige aluminiumspoler mellem produktionslinjer, bufferlagringsområder og afsendelseszoner. Uanset om den er installeret i et nyt automatiseret anlæg eller eftermonteret i et eksisterende værksted, leverer den driftskontinuitet og materialbeskyttelse i alle faser.

| Systemkonfiguration: Forældrekurv | Mounted on rails, with saddle + conveyor system;Child Cart |

| Løftekapacitet | 5 – 60 tons (customizable per coil weight and dimensions) |

| Rejsehastighed | Up to 60 m/min (adjustable via frequency inverter) |

| Positioneringsnøjagtighed | ±2 mm med sensorbaseret justering |

| Sportype | Indlejret stål skinne eller overhead-styret ledning |

| Drevtype | Electric motor + gear reducer with soft-start control |

| Strømforsyning | Cable drum / low-voltage rail / battery (site-dependent) |

| Sikkerhedssystemer | Detektion af forhindringer, overbelastningsbeskyttelse, nødstop |

| Overholdelse | ISO, GB, CE-certificerede komponenter |

Udfyld nedenstående formular for at få øjeblikkelig adgang til krankataloget og tale med vores tekniske team for anbefalinger