- Power Industry

-

Share:

Overview

Power generation facilities — from fossil fuel to nuclear, hydro, wind, and solar — rely on precision lifting for maintenance, assembly, and equipment installation. Cranes in power plants face unique challenges: high lifting heights, narrow spaces, and absolute safety requirements. Our lifting solutions are engineered for reliability, safety, and long-term service in the most demanding energy environments.

We provide tailored crane systems for turbine halls, generator maintenance, transformer workshops, and renewable energy plants.

Request for QuotationTurbine Hall Cranes

Designed for precise lifting of turbines, generators, and rotors during installation and overhauls. Henan Mine’s turbine hall cranes are engineered for high-precision lifting and positioning of heavy rotating equipment such as turbines, generators, and rotors during installation, maintenance, or complete overhaul. In power-supplying pulp mills where energy recovery is critical, these cranes support thermal system reliability by enabling safe and efficient handling of core power machinery. Featuring fine control systems and multi-point load balancing, they reduce downtime and ensure equipment longevity during every major service cycle.

Maintenance Overhead Cranes

Installed in control rooms, boiler areas, and switchyards for ongoing inspection and part replacement. Installed across control rooms, boiler zones, and switchyards, Henan Mine’s maintenance overhead cranes facilitate daily inspections and part replacements in high-heat, confined areas. For paper mills with integrated steam and power systems, these cranes play a vital role in handling pumps, motors, and heat exchangers without interrupting continuous operations. Their compact design and precision movement make them indispensable for preventive maintenance tasks

Transformer Bay Cranes

High-lift cranes customized for handling large transformers, coils, and electrical cabinets. Our transformer bay cranes are tailored for vertical lifting of large transformers, coils, and high-voltage cabinets. In pulp and paper facilities equipped with on-site substations, these cranes ensure safe transfer and positioning of delicate electrical gear during setup and upgrade work. The cranes can be adapted with specialized spreaders and insulation-safe lifting tools to meet strict operational standards in sensitive zones.

Renewable Energy Cranes

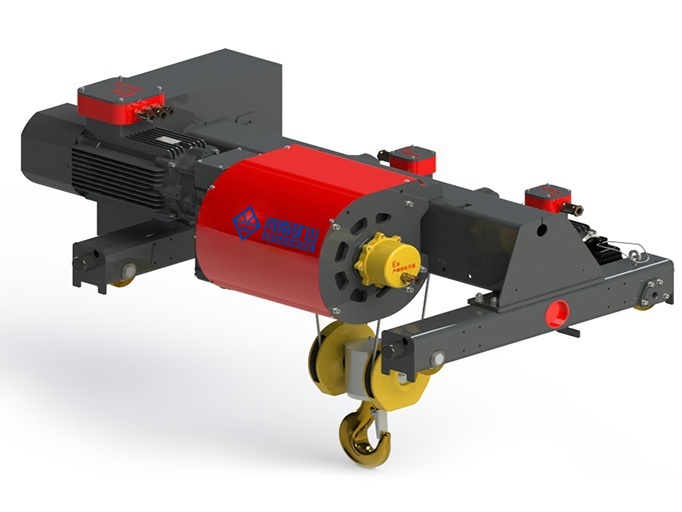

Smart, lightweight hoists for handling wind turbine gearboxes, solar panel lines, and battery packs. As more modern paper mills adopt hybrid and renewable power solutions, Henan Mine’s lightweight hoists are ideal for maintaining wind turbine components, solar panel lines, and battery energy storage systems. These cranes support rapid access to gearboxes, drives, and control panels, minimizing operational disruption. With options for mobile bases and modular arms, they align with the sustainability goals of low-emission industrial plants.

Explosion-proof Cranes (Optional)

For use in gas-fired power stations and flammable areas. For power sectors within pulp plants that rely on gas-fired turbines or store combustible materials, Henan Mine offers optional explosion-proof crane systems. Built with ATEX-certified components and flameproof enclosures, these cranes provide peace of mind in flammable zones. They are suitable for areas near gas supply modules or solvent storage rooms, offering safe lifting without compromise.

Key Features

Precision control with variable frequency drives (VFD)

Load anti-sway and positioning sensors

Redundant safety brake systems

Insulation layer for high-heat areas

Customized spans for limited workshop widths

Customer Story: Combined-Cycle Power Station – Eastern Europe

Challenge:

Client required an overhead crane system for precise lifting of 30ton turbine parts inside a limited-clearance turbine hall.

Solution:

Engineered a 30t double girder overhead crane with 24m span

Included VFD, anti-sway, and temperature-resistant components

Provided on-site installation guidance with remote monitoring setup

Result:

Reduced turbine servicing time by 42% and avoided external lifting rentals.

Client feedback: “Your team worked hand-in-hand with our engineering department. Great job.”

Application Areas

| Power Plant Zone | Crane Type / Use |

| Turbine Hall | Double girder overhead crane |

| Generator Area | Precision maintenance crane |

| Control Room & Workshops | Light-duty hoists or jib cranes |

| Transformer Yard | Gantry cranes or mobile units |

| Solar & Wind Workshops | Lightweight electric hoists |

We Support You at Every Stage

Project layout planning & CAD drawing

Factory acceptance testing (FAT)

Overseas installation supervision

Annual maintenance contracts