- Forging the Future: Henan Mine Equips All Cranes with Precision-Engineered Forged Wheels

-

Release Time:2025-04-18 20:11:22Share:

Forging the Future: Henan Mine Equips All Cranes with Precision-Engineered Forged Wheels

Smarter processes, stronger performance—ushering in a new era of high-efficiency crane manufacturing

Henan Mine Crane

What Happens When You Give a Crane “Invincible Wheels”?

In the quest for stronger, smarter, and more sustainable lifting equipment, Henan Mine Crane Co., Ltd. has taken a bold step forward by making forged wheels a standard feature across its entire product line—covering all crane types, from gantry and bridge cranes to custom-engineered solutions.

These high-performance wheels, manufactured through an advanced intelligent forging and rolling process, are more than just components—they are a core driver of durability, energy efficiency, and product excellence.

From Raw Steel to Powerhouse Performance

Craftsmanship meets cutting-edge technology

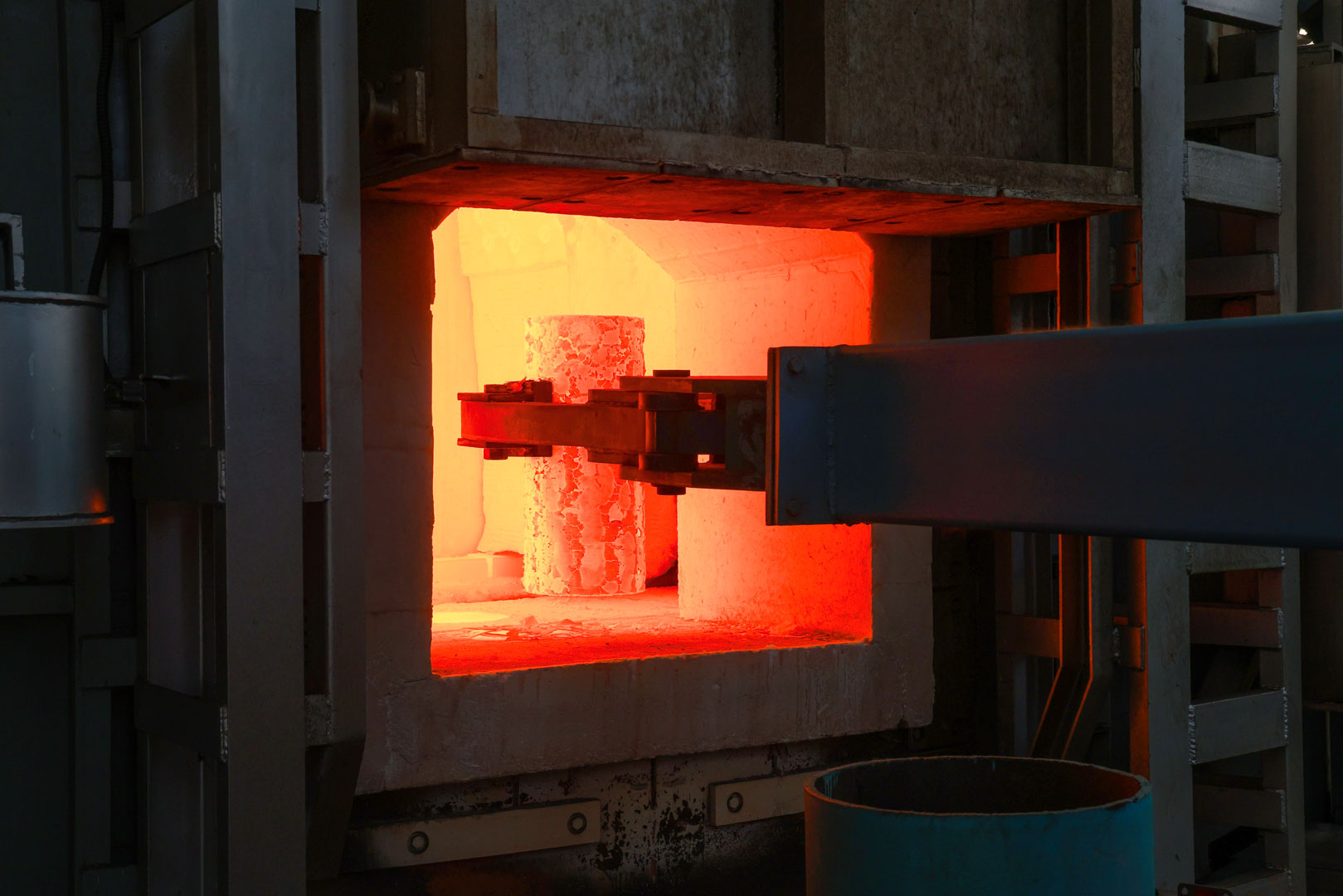

At the heart of Henan Mine’s forged wheel production is an integrated, high-speed forging process that combines heating, conveying, forging, rolling, and heat treatment into one seamless flow. High-quality raw materials are subjected to immense pressure from a 10,000-ton forging press, resulting in wheels with exceptional internal strength and refined microstructure.

This process not only enhances material density and grain uniformity but also drastically improves the wheel’s resistance to wear, fatigue, and deformation—crucial for cranes operating under high loads and continuous duty cycles.

Superior Strength, Extended Service Life

Henan Mine’s forged wheels deliver:

Higher load-bearing capacity

Improved toughness and fatigue resistance

Tighter structural integrity

Lower maintenance frequency and lifecycle costs

For customers, this means increased uptime, longer equipment life, and peace of mind in critical operations—whether in steel mills, ports, or energy projects.

Green, Flexible, and Future-Ready

The production line features modular composite equipment, enabling flexible, high-efficiency manufacturing. With minimal material waste, low emissions, and reduced energy consumption, the process reflects our commitment to green manufacturing and low-carbon development.

Key innovations include:

Multi-station rolling and precision shaping

Minimal machining allowance for high material utilization

Shorter production cycles and lower environmental impact

A Strategic Upgrade to the Entire Industrial Chain

Henan Mine’s intelligent forging line is more than just a technical achievement—it’s a cornerstone of our full-spectrum manufacturing system. It enables:

End-to-end quality control

Consistent product performance

Greater flexibility to meet custom project demands

Lower cost per unit through optimized energy use and material flow

This strategic investment underscores our broader mission: to lead the crane industry toward a smarter, cleaner, and more capable future.