Insulated Feeding Overhead Crane for Electrolytic Aluminum

Insulated Feeding Overhead Crane for Electrolytic Aluminum

Engineered by Henan Mine – Safe, Precise, and Built for Harsh Environments

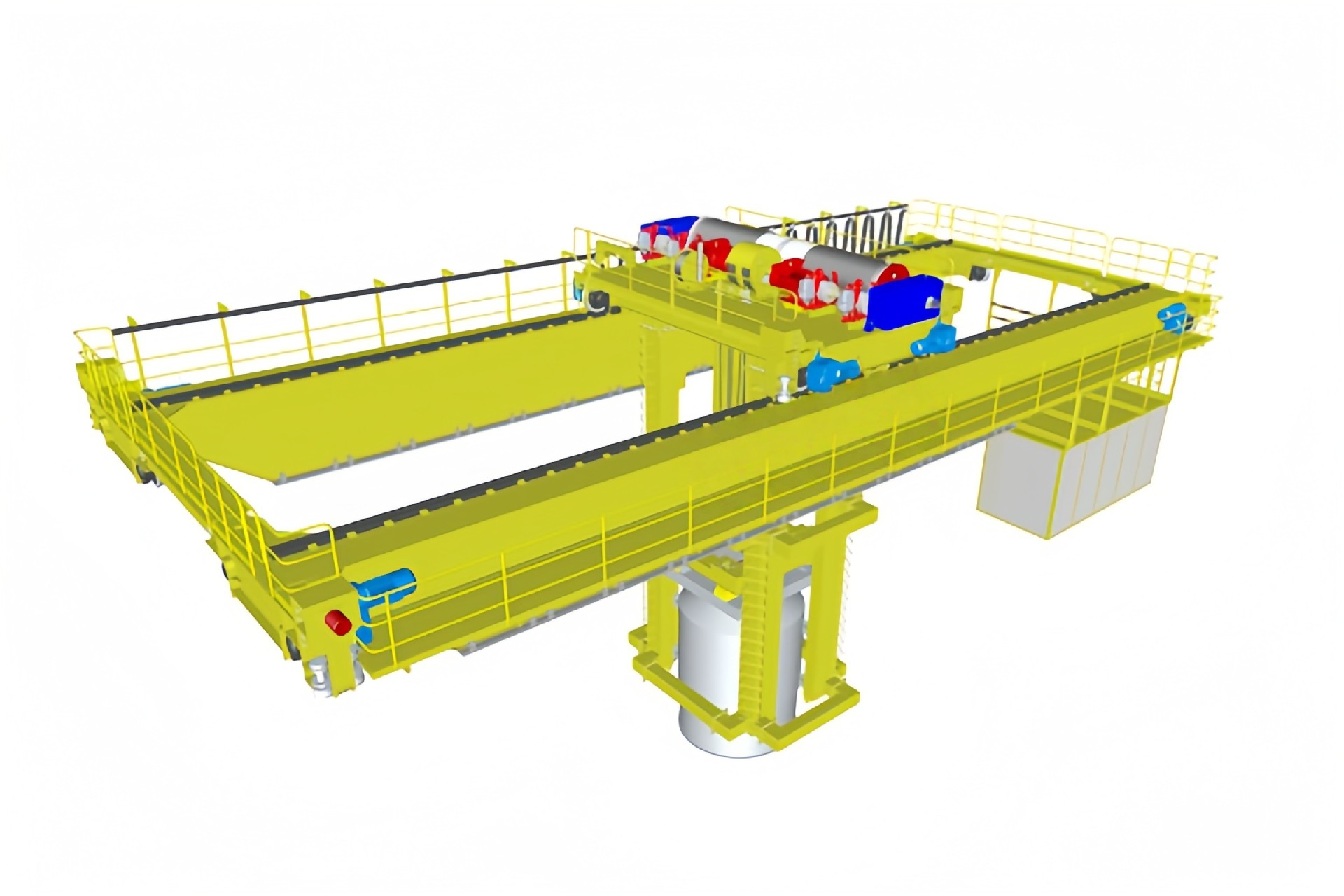

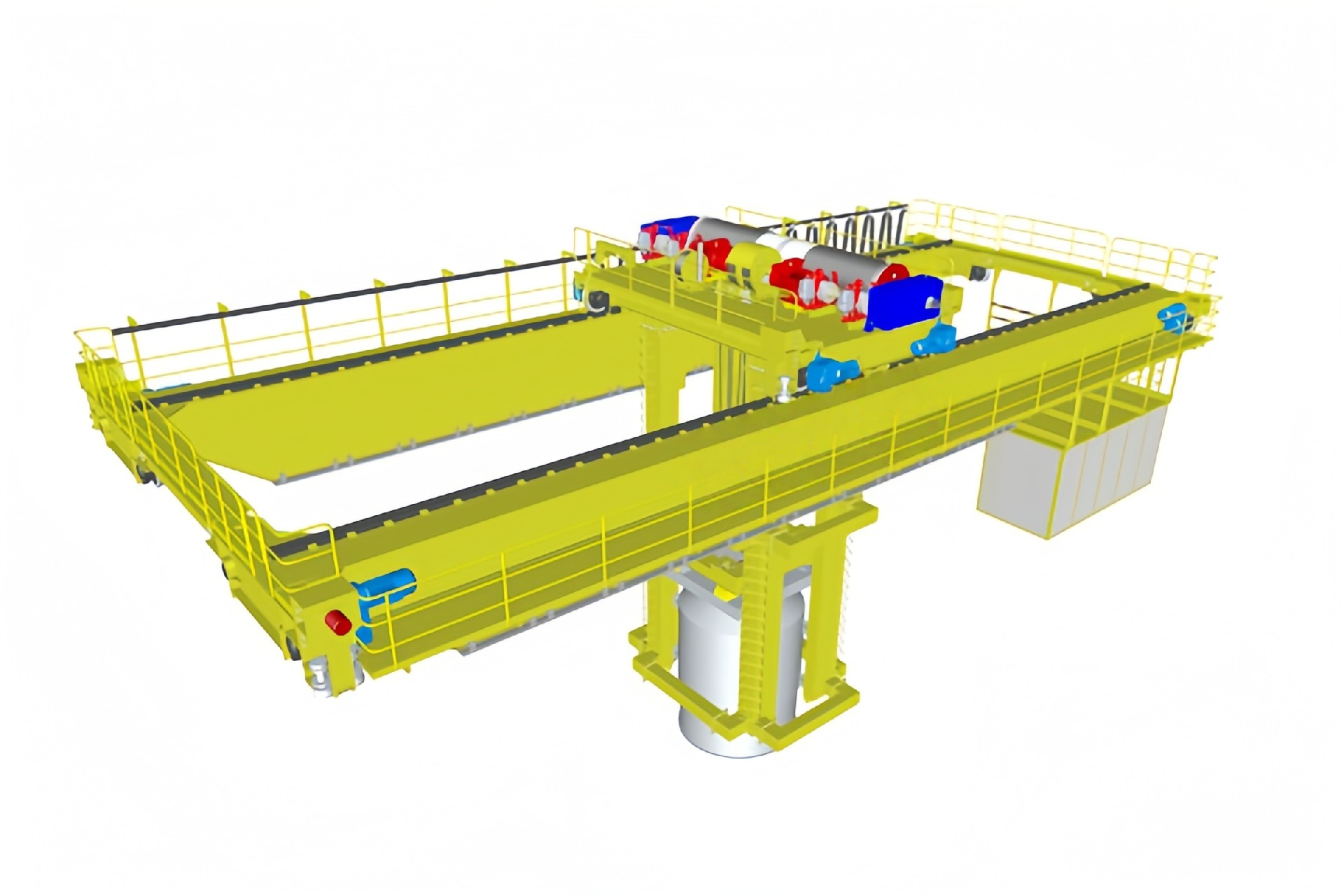

The Henan Mine Insulated Feeding Overhead Crane is an advanced overhead lifting system, specifically developed for the electrolytic aluminum industry, where extreme operating conditions—such as high-temperature molten salt, heavy current, strong magnetic fields, and corrosive atmospheres—demand highly specialized solutions.

This crane combines high-voltage insulation technology, anti-magnetic design, and a dedicated feeding trolley to perform key production tasks including aluminum fluoride feeding, molten aluminum extraction, cell structure handling, and more. Trusted by top aluminum producers, it plays a central role in ensuring continuous, safe, and automated operations within smelting plants.

| Rated Lifting Capacity | Custom-configured (typically 10–74 tons) |

| Crane Configuration | Three-beam, three-trolley layout |

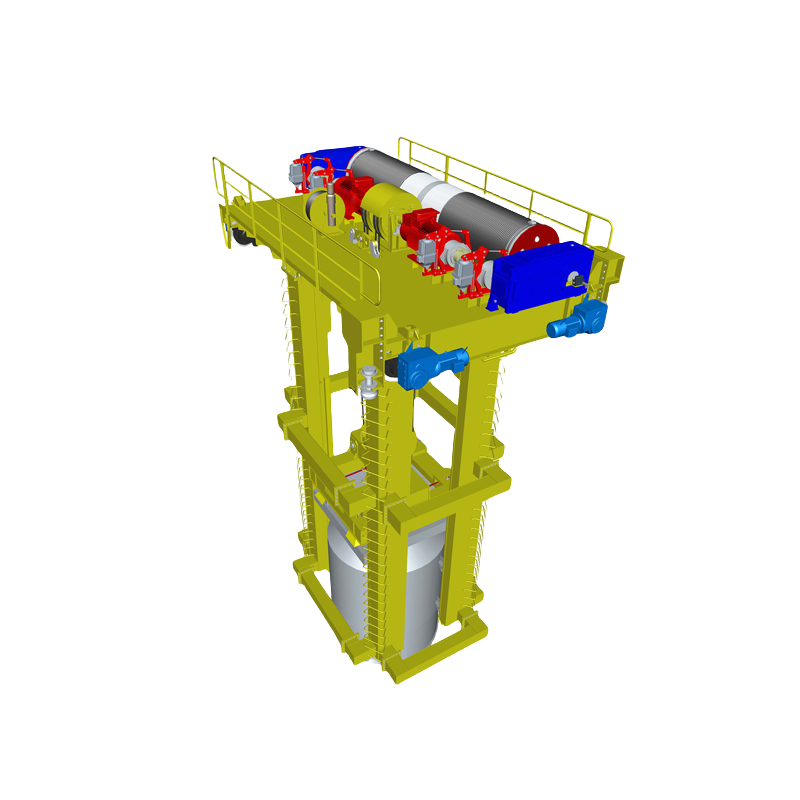

| Special Trolleys | Tool Trolley (hook-type lifting);Aluminum Extraction Trolley (with insulated, anti-sway hook & weighing system);Feeding Trolley (with hopper, discharge system & electronic measuring unit) |

| Travel Mechanism | 8-wheel, dual-drive with shaft-mounted 3-in-1 reducers |

| Control Modes | Cabin control + remote diagnostics |

| Environmental Resilience | Anti-corrosion materials + sealed electronics |

| Operator Cabin | Equipped with industrial HVAC for extreme temperature conditions |

| Safety Standards | GB, ISO, CE-compliant |

Fill in the form below to get instant access to the cranes catalogue and speak to our technical team for recoomendations