Underhung Overhead Crane

Underhung Overhead Crane

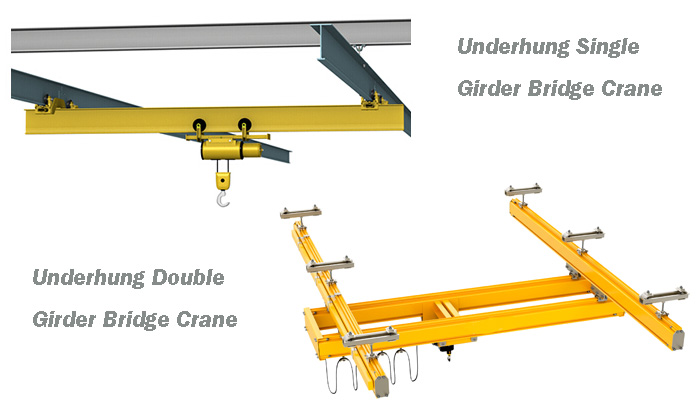

The underhung overhead crane, also referred to as an under running or under slung bridge crane, is designed to maximize facility space and deliver cost-effective, flexible lifting solutions. Suspended from the roof structure, it eliminates the need for floor-mounted runway columns, making it ideal for workshops, warehouses, and industrial production lines where free floor space is a priority.

Engineered for lighter loads—typically up to 10 tons—this crane system offers smooth, precise load handling, enhanced safety features, and a modular design. Whether you’re transporting materials along a fixed path or working in a bay with multiple cranes, the underhung system offers excellent adaptability and ergonomic operation.

Note: Custom configurations available based on project requirements.

| Parameter | Specification |

| Lifting Capacity | 0.5 – 10 tons |

| Span | 3 – 16 meters |

| Working Class | A3 – A4 |

| Ambient Temperature | -20°C to +40°C |

| Installation Type | Ceiling-suspended (roof/rafter mounted) |

| Structure Types | Single Girder / Double Girder |

| Control Options | Pendant control, Remote control, or both |

Comparison Table: Underhung vs. Top-Running Cranes

| Feature | Underhung Crane | Top-Running Crane |

| Mounting | Suspended from ceiling | Mounted on top of runway rails |

| Floor Columns Needed | ❌ No | ✅ Yes |

| Lifting Capacity | Up to 10 tons | Up to 300+ tons |

| Space Efficiency | ✅ Excellent | Moderate |

| Structural Load | Lower | Higher |

| Track Misalignment Risk | Lower (bolted to structure) | Higher (requires frequent alignment checks) |

| Cost of Installation | Lower (less structure required) | Higher (more supports & rails needed) |

| Maintenance Downtime | Longer if realignment needed | Easier realignment |

| Best For | Tight spaces, light loads, precise paths | Heavy-duty lifting and long spans |

Fill in the form below to get instant access to the cranes catalogue and speak to our technical team for recoomendations