Explosion-Proof Automated Cleanroom Crane

Explosion-Proof Automated Cleanroom Crane

Precision Lifting for the Semiconductor Era

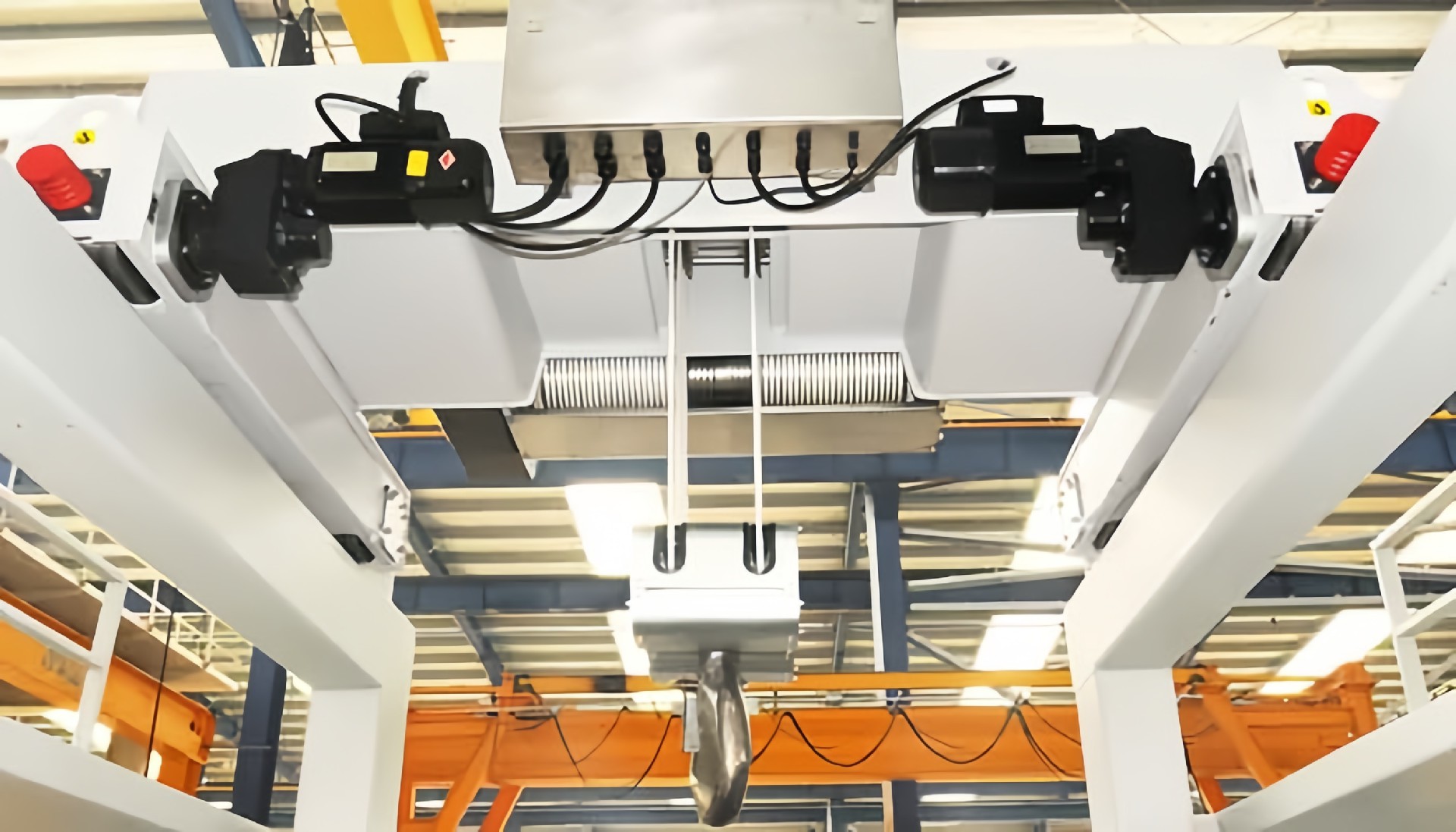

The Henan Mine Explosion-Proof Cleanroom Crane is a high-precision, fully automated lifting system built to meet the strictest cleanliness and safety standards in advanced semiconductor production and microelectronics assembly. Engineered for ISO Class 4 (Class 7 GB) cleanroom environments and certified to dIICT4 explosion-proof standards, this crane is designed to safely handle materials in flammable gas zones without compromising air purity or production efficiency.

With centralized computer automation, laser positioning, and fully sealed, stainless-steel components, it offers high-speed, contaminant-free lifting with unmatched reliability.

| Parameter | Specification |

| Cleanroom Grade | ISO Class 4 (GB Class 7) |

| Explosion-Proof Rating | dIICT4 |

| Control System | Centralized automated computer system |

| Positioning System | Laser barcode positioning (trolley & bridge) |

| Operational Modes | Manual / Automatic (switchable & interlocked) |

| Motor Type | Fanless, explosion-proof, high-protection motor |

| Materials | Stainless steel, anti-static, sealed corrosion-resistant |

| Bearings & Brakes | Self-lubricating, sealed bearings; double-sealed brakes |

| Emergency Safety | Remote E-stop, power-fault hold |

CUSTOMER PAIN POINTS – SOLVED

| Pain Point | Henan Mine Solution |

| Risk of contamination in cleanrooms | ✅ Fully sealed design, ISO Class 4 compliant components |

| Presence of flammable/explosive gases | ✅ Certified dIICT4 explosion-proof crane structure |

| Manual handling slowing down semiconductor processes | ✅ Full automation with centralized control and precise positioning |

| Downtime due to maintenance and failure | ✅ Maintenance-free bearings, sealed gearboxes, fault pause system |

| Inconsistent load positioning damaging fragile components | ✅ Laser-guided trolley and bridge travel with mm-level accuracy |

Fill in the form below to get instant access to the cranes catalogue and speak to our technical team for recoomendations