- Waste-to-Energy & Biomass Cranes

-

Share:

Smart, Reliable, and Custom-Engineered Lifting & Steel Structure Solutions

As waste-to-energy (WTE) and biomass power plants continue to expand worldwide, the demand for high-efficiency material handling systems and durable steel structures has never been greater. These facilities require cranes that can operate 24/7, handle corrosive and high-temperature environments, and integrate seamlessly with automated plant workflows.

We combine the best of both worlds — advanced smart lifting technologies and heavy-duty structural engineering — to deliver fully customized solutions for your WTE and biomass projects.

Automatic Grab Bucket Cranes (Waste Feeding)

Fully automated overhead cranes used to transport and feed municipal solid waste into the incinerator. These systems run around the clock, operating with high efficiency, precise grab control, and programmable feeding cycles to support continuous furnace operation.

Ash Handling Cranes (Bottom Ash / Fly Ash)

Specially designed cranes for the safe and efficient collection and transfer of both bottom ash and fly ash after combustion. Built with dust-resistant components and anti-corrosive features to withstand harsh conditions inside the ash processing zone.

Maintenance Cranes (Turbine, Boiler, Control Areas)

Compact and heavy-duty cranes installed across key plant areas—such as the turbine hall, boiler section, and control room—to assist with equipment inspection, repairs, and part replacement during scheduled maintenance shutdowns.

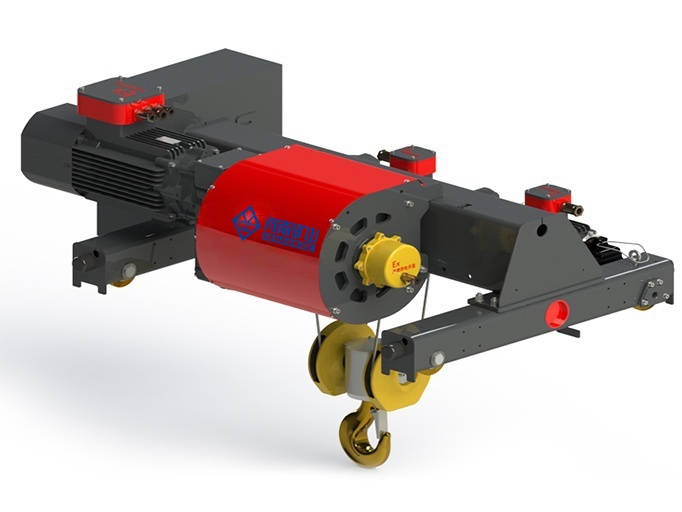

Explosion-Proof Cranes (Optional for Flammable Zones)

Available as an option for facilities handling volatile gases or chemical byproducts. These cranes are equipped with flameproof motors, spark-resistant wiring, and sealed control enclosures to ensure safe lifting in potentially hazardous areas.

Tailored Engineering, Built for Your Site

Every crane system and steel structure we deliver is engineered to match the unique characteristics of your operation—from the dimensions of the waste pit to the handling volume and working schedule. Whether you're installing a refuse grab crane, ash removal unit, or supporting steel frame, each component is customized to fit the actual conditions of your facility—ensuring reliable, long-term performance.

Intelligent Operation & Automation

Our solutions are designed to simplify daily operations while enhancing safety and efficiency. Available smart features include:

Pre-programmed waste handling cycles

Load sway suppression and real-time weight tracking

Remote monitoring with control room connectivity

Intelligent grab positioning powered by AI and optimized stacking algorithms

High Durability & Safety

Heat- and corrosion-resistant hoists and grabs

Explosion-proof options for gas zones

Redundant brakes and smart overload protection

Continuous-duty mechanisms for non-stop operation

Integrated Steel Structure Solutions

Unlike many global brands who outsource structures, we offer in-house fabrication of crane-supporting steel pits, bridges, and platforms — reducing lead time, ensuring quality, and simplifying on-site installation.

Application Overview

| Plant Area | Equipment Type |

| Waste Pit | Automatic Grab Crane |

| Ash Conveyor/Storage | Ash Handling Crane |

| Boiler & Turbine Rooms | Maintenance Overhead Cranes |

| Biomass Fuel Yard | Stacker Cranes or Gantries |

| Flammable Zones | ATEX/Explosion-Proof Cranes |

Service & Support You Can Rely On

Feasibility Study & Layout Design

CAD/3D Modeling + Structural Engineering

Factory Acceptance Testing (FAT)

On-site Installation & Supervision

Remote Monitoring Setup

Annual Maintenance & Spare Parts Supply

Ready to Power Up with Smarter Handling?

Whether you are building a new WTE plant or upgrading an existing one, we offer a fully integrated solution that combines smart lifting systems and structural expertise — all from a single trusted supplier.