- What is the difference between gantry cranes and bridge cranes?

-

Share:

What is the difference between gantry cranes and bridge cranes?

In industrial production, logistics and warehousing, and various large-scale construction projects, cranes play a crucial role as key material handling equipment. Gantry cranes and bridge cranes are two of the most widely used types among numerous crane categories. Although both are tasked with lifting heavy loads, they differ significantly in terms of structural design, operational characteristics, applicable scenarios, and cost-effectiveness. For businesses and projects, accurately understanding these differences is crucial for rational selection, efficient operations, and reducing operational costs. In the following sections, we will delve into the various characteristics of gantry cranes and bridge cranes, providing a comprehensive overview of their differences.

I. Structural Design Differences

(1) Analysis of Bridge Crane Structure

Bridge cranes, commonly referred to as ‘overhead cranes,’ feature a bridge-like structure spanning the ceiling of a workshop, warehouse, or material yard, with both ends securely supported by tall concrete columns or metal frames. The bridge frame, as the primary load-bearing structure, is typically composed of main beams and end beams, which are connected via welding or high-strength bolts to form a sturdy framework. On the main beams, tracks are laid for the hoist trolley to run along, and the hoist trolley is equipped with a lifting mechanism capable of vertically lifting and horizontally moving loads along the bridge frame. Additionally, the bridge crane is equipped with a trolley travel mechanism, which drives the entire bridge structure along tracks laid on elevated structures on both sides for longitudinal movement.

Taking a common general-purpose bridge crane as an example, its main beam typically adopts a box-type structure, which offers excellent bending and torsional resistance, enabling it to withstand significant loads. The end beams are generally box-type or truss structures, and when connected to the main beam, they ensure the overall stability of the bridge structure. The main girder travel mechanism usually adopts a separate drive configuration, where two independent drive units drive the wheels at both ends of the bridge frame, enabling the crane to move smoothly along the tracks. The trolley travel mechanism consists of the trolley frame, trolley travel mechanism, and hoisting mechanism. The trolley's drive wheels are closely spaced and driven by a single trolley motor, allowing the trolley to move flexibly along the bridge frame.

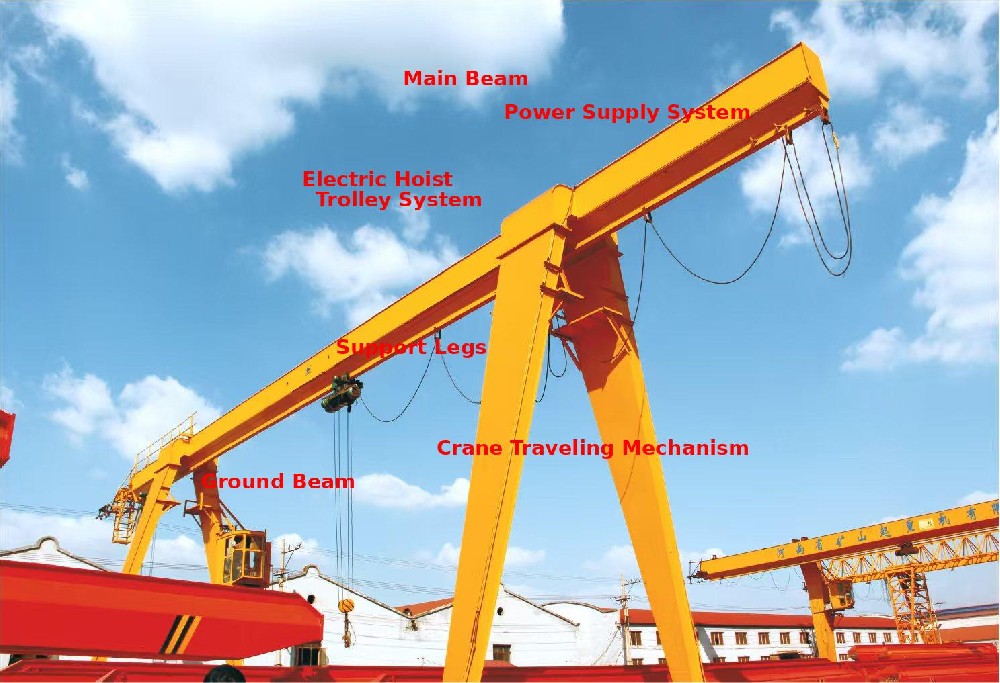

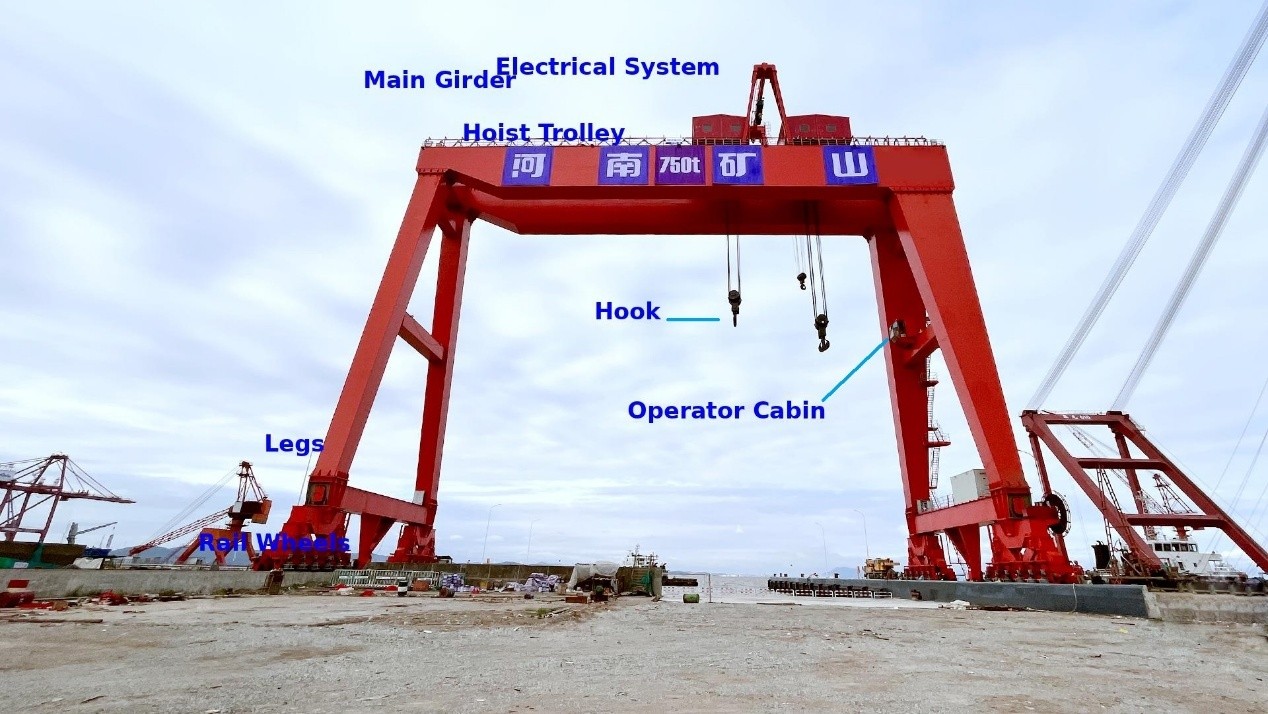

(2) Structural Analysis of Gantry Cranes

Gantry cranes, also known as portal cranes, feature a metal structure resembling a large portal frame. Below the main beam, two sturdy legs are installed, with wheels or tracks at the bottom, enabling direct movement along ground tracks. Some gantry cranes also have extended cantilever beams at both ends of the main beam to further expand the operational range. Gantry cranes primarily consist of the gantry frame, hoist travel mechanism, hoist trolley, and electrical components.

The gantry frame is the core structure of the gantry crane, comprising the main beam, legs, and upper and lower crossbeams. The main beam can adopt various structural forms, such as box beams, truss beams, or composite beams, depending on usage requirements and load capacity. The legs are typically box-type or truss-type structures, with their height and strength designed based on factors such as the crane's span, lifting capacity, and working environment. The trolley travel mechanism drives the entire crane along the ground tracks, typically using either centralised or individual drive systems. The hoist trolley is similar to that of a bridge crane, mounted on the main beam's tracks to lift and move loads horizontally.

(3) Summary of structural differences

From a structural perspective, bridge cranes rely on elevated tracks in buildings to support the bridge frame, with a relatively simple structure primarily focused on the bridge frame and hoist trolley components; gantry cranes, however, achieve independent standing and operation through their own legs, without requiring support from buildings. The gantry structure is more complex, necessitating consideration of leg stability and load-bearing capacity. Additionally, gantry cranes can be equipped with cantilever beams at both ends of the main beam, a feature not available in bridge cranes, giving gantry cranes a certain advantage in expanding their operational range.

II. Differences in Operational Characteristics

(1) Operational Characteristics of Bridge Cranes

Movement Forms: Bridge cranes have three primary movement forms. The main hoist motor drives the bridge structure to move forward and backward along the longitudinal tracks in the workshop; the trolley motor drives the hoist trolley to move horizontally along the tracks on the bridge structure; and the lifting motor drives the load for vertical lifting and lowering movements. These three movements work in conjunction to achieve precise lifting and handling of loads in three-dimensional space.

Lifting Height and Capacity: The lifting height of bridge cranes is typically designed based on the height of the factory building, ranging from several metres to tens of metres. The lifting capacity also varies widely, from a few tonnes to hundreds of tonnes. In large-scale industrial sectors such as steel manufacturing and heavy machinery processing, bridge cranes with lifting capacities of hundreds of tonnes are often used to meet the demand for handling large steel ingots, heavy machinery equipment, and other heavy loads.

Working speed: The working speed includes the travel speed of the main crane, the travel speed of the trolley, and the lifting speed. Different types and applications of bridge cranes have varying working speeds. Generally, bridge cranes used in scenarios requiring frequent lifting and rapid operations have relatively high travel speeds; however, in scenarios with high precision requirements for lifting, the speed is appropriately reduced to ensure smooth and accurate lifting operations.

Positioning accuracy: Since bridge cranes primarily operate in fixed workshops or warehouses with relatively stable tracks, they can achieve high positioning accuracy through advanced electrical control systems and precise mechanical transmission devices, meeting the strict requirements of production processes for material handling positions.

(2) Working Characteristics of Gantry Cranes

Movement Forms: Gantry cranes also possess the three basic movement forms of main crane longitudinal movement, trolley lateral movement, and vertical lifting of loads. However, unlike bridge cranes, the main crane of a gantry crane operates on ground tracks, offering greater flexibility in its travel range. It can not only operate on straight tracks but also be equipped with curved tracks according to site requirements to achieve more complex operational paths.

Lifting Height and Capacity: The lifting height and capacity of gantry cranes can also be customised according to actual requirements. In ports and terminals, gantry cranes used for handling containers typically have a high lifting height, reaching tens of metres, to meet the requirements of ship loading and unloading operations. In terms of lifting capacity, gantry cranes range from small units handling a few tonnes to large units handling hundreds of tonnes, catering to the needs of handling cargo of various scales.

Working speed: The working speed of gantry cranes can also be adjusted according to the operational environment. In scenarios requiring rapid cargo handling, such as ports and terminals, the travel speeds of the main and auxiliary hoists are typically faster to enhance operational efficiency. In contrast, in construction sites or precision equipment handling scenarios where lifting accuracy is critical, the speed is relatively slower.

Positioning accuracy: Although gantry cranes generally have lower positioning accuracy than bridge cranes, with the continuous advancement of technology, their positioning accuracy is gradually improving through the use of advanced sensor technology and automated control systems, enabling them to meet the positioning requirements of most routine operations.

(3) Summary of operational characteristic differences

Overall, bridge cranes have certain advantages in terms of lifting height and positioning accuracy, making them more suitable for indoor environments with relatively fixed conditions and tasks requiring high lifting precision. Gantry cranes, however, offer greater flexibility in their working range due to their unique ground-based movement, and can also meet various requirements in terms of lifting height and load capacity, particularly for material handling operations in open outdoor areas.

III. Differences in Applicable Scenarios

(1) Applicable Scenarios for Bridge Cranes

Industrial production workshops: In industrial production workshops such as mechanical manufacturing, automobile manufacturing, and steel smelting, bridge cranes are indispensable material handling equipment. For example, in mechanical manufacturing workshops, bridge cranes can be used to lift raw materials, semi-finished products, and finished goods, precisely transferring them between different processing stations to support the efficient operation of production lines. In automotive manufacturing workshops, they can be used to handle automotive components and vehicle bodies, enabling material distribution on automated assembly lines. In steel smelting workshops, they can lift high-temperature steel ladles and large steel ingots, ensuring the continuity of production processes.

Warehouses and logistics centres: In indoor warehouses and logistics centres, bridge cranes can fully utilise the warehouse's vertical space to achieve efficient stacking and storage of goods. They can quickly lift goods from transport vehicles and move them to designated storage areas, or remove goods from warehouse shelves for loading and shipping, thereby improving warehouse storage and turnover efficiency.

Indoor large-scale equipment installation and maintenance: During the installation, commissioning, or maintenance of indoor large-scale equipment, bridge cranes can utilise their precise positioning capabilities and high lifting capacity to accurately lift equipment components to their installation locations or remove damaged components for repair and replacement during maintenance, ensuring the smooth progression of equipment installation and maintenance work.

(2) Applications of gantry cranes

Ports and terminals: Ports and terminals are one of the most common applications for gantry cranes. Container gantry cranes can quickly and efficiently load and unload containers, lifting them from ships and transporting them to terminal yards, or lifting containers from yards onto ships, meeting the large-scale cargo handling needs of ports. Additionally, at bulk cargo terminals, gantry cranes can be equipped with grab buckets or other material-handling devices to load and unload bulk cargo such as coal, ore, and grain, thereby enhancing the terminal's loading and unloading efficiency.

Construction sites: At construction sites, gantry cranes can be used to lift construction materials such as steel, precast concrete components, and bricks, transporting them from the ground to different floors or construction areas of buildings. Their flexible operational range and high lifting capacity enable them to adapt to the complex construction environments and diverse lifting requirements of construction sites, providing strong support for the smooth progress of construction projects.

Open-air cargo yards and logistics parks: In open-air cargo yards and logistics parks, gantry cranes can perform loading, unloading, and handling operations for various types of cargo. For example, in large steel markets, gantry cranes can lift steel of different specifications, enabling the storage, sorting, and distribution of steel. In logistics parks, they can be used to handle large equipment, containers, and other cargo, improving the logistics efficiency of open-air sites.

(3) Summary of Differences in Applicable Scenarios

In summary, bridge cranes are primarily suitable for indoor environments, especially industrial production workshops and warehouses where continuous production processes and high precision in material handling are required. Gantry cranes, on the other hand, are more suited for outdoor operations, such as ports, terminals, construction sites, and open-air cargo yards, where they can leverage their advantages of a wide operational range and high lifting capacity in complex and open environments.

IV. Cost-Benefit Differences

(1) Cost-Benefit Analysis of Bridge Cranes

Initial Purchase Cost: The initial purchase cost of bridge cranes is relatively high, primarily due to their structural design requiring compatibility with building overhead tracks, which demands advanced manufacturing processes and high-quality materials. Additionally, large-scale, high-precision bridge cranes equipped with advanced electrical control systems and safety protection devices further increase procurement costs.

Installation and Maintenance Costs: Installing a bridge crane requires certain modifications to the building structure to install overhead tracks and support structures, which involves structural reinforcement and construction work, resulting in higher installation costs. In terms of maintenance, since the bridge crane's running tracks are fixed to the building structure, some maintenance tasks require specialised high-altitude work equipment and technical personnel, making maintenance more challenging and costly. Additionally, the electrical systems and mechanical components of bridge cranes have high maintenance requirements, necessitating regular inspections, maintenance, and repairs to ensure safe operation and normal service life.

Long-term usage benefits: Over the long term, bridge cranes can significantly improve production efficiency and reduce labour costs thanks to their efficient and precise material handling capabilities. Their advantages are particularly evident in large-scale, high-frequency material handling operations. Additionally, through reasonable equipment selection and maintenance management, bridge cranes have a long service life and can provide businesses with good long-term investment returns.

(2) Cost-benefit analysis of gantry cranes

Initial Purchase Cost: The initial purchase cost of gantry cranes is relatively low, especially for smaller, simpler models, which have simpler structures and lower manufacturing process and material requirements, making them more cost-effective. For larger, special-purpose gantry cranes, while the purchase cost may increase, they still offer a price advantage compared to bridge cranes of the same lifting capacity and specifications.

Installation and Maintenance Costs: The installation of gantry cranes is relatively straightforward, requiring only the laying of tracks on the ground or foundation preparation, without the need for major structural modifications to buildings, resulting in lower installation costs. In terms of maintenance, due to their relatively open structure, most components are easily accessible and maintainable, making maintenance less challenging. Additionally, gantry cranes have fewer moving parts, resulting in lower wear and tear and a reduced likelihood of malfunctions, thereby keeping maintenance costs relatively low.

Long-term usage benefits: Gantry cranes offer high adaptability and flexibility in outdoor operational scenarios, capable of meeting the needs of various operational environments and tasks. In short-term or temporary projects, the cost advantage of gantry cranes becomes more evident, potentially saving significant equipment investment costs for projects. Furthermore, with ongoing technological advancements, the performance and reliability of gantry cranes continue to improve, leading to enhanced long-term usage benefits.

(3) Summary of cost-benefit differences

From a cost-benefit perspective, although bridge cranes have higher initial procurement, installation, and maintenance costs, they can achieve better investment returns by improving production efficiency and reducing labour costs in long-term, large-scale, high-precision material handling operations. Gantry cranes, on the other hand, offer a clear cost advantage in outdoor operations and short-term projects due to their lower initial procurement and installation costs, as well as relatively simple maintenance requirements. When selecting crane types, enterprises should comprehensively consider factors such as project duration, operational environment, usage frequency, and budget, weigh the cost-benefit ratios of both options, and make the most appropriate decision.

5. Differences in Safety Performance

(1) Safety Performance of Bridge Cranes

Structural Safety: The bridge structure of bridge cranes is designed through rigorous mechanical calculations and verification, capable of withstanding the rated load capacity and various operational loads. The main beams and end beams are manufactured using high-strength steel and secured through advanced welding techniques or bolted connections to ensure structural stability. Additionally, stress monitoring points are installed at critical locations on the bridge frame to continuously monitor structural stress conditions. If any abnormalities are detected, measures can be promptly taken to address them, ensuring the structural safety of the crane.

Operational Safety: The hoist's operating mechanisms are equipped with multiple safety protection devices. At both ends of the main and auxiliary crane tracks, travel limit switches are installed. When the crane reaches its极限 position, the limit switches automatically activate, stopping the crane's movement to prevent derailment accidents. Additionally, buffers are installed to absorb energy during collisions, reducing impact force and protecting both equipment and personnel safety. In terms of the hoisting mechanism, load limiters and hoisting height limiters are installed. When the lifted load exceeds the rated value or the hook reaches the maximum height, the system automatically cuts off the power supply and stops the hoisting action to prevent overloading and top-out accidents.

Electrical Safety: The electrical system of the bridge crane adheres to strict safety design standards. All electrical equipment has excellent insulation performance to prevent electrical leakage accidents. Additionally, leakage protection devices, short-circuit protection devices, and overload protection devices are installed to provide comprehensive protection for the electrical system. Furthermore, advanced grounding technology is adopted to ensure reliable grounding of electrical equipment, further enhancing the safety of the electrical system.

(2) Safety Performance of Gantry Cranes

Structural Safety: The gantry structure of gantry cranes is also carefully designed and calculated, with the strength and stability of the legs and main beams meeting usage requirements. During manufacturing, strict control is exercised over the quality of steel materials and welding processes to ensure structural reliability. To prevent overturning accidents in adverse weather conditions such as strong winds, anti-wind devices such as anti-wind track clamps and anti-wind guy wires are typically installed to enhance the structural safety of the crane in harsh environments.

Operational safety: The main hoist travel mechanism and trolley travel mechanism of the gantry crane are also equipped with similar safety protection devices, such as travel limit switches and buffers, to ensure safety during operation. Since gantry cranes are often operated outdoors, some equipment is also fitted with track cleaning devices and foreign object detection devices to prevent debris on the tracks from affecting crane operation. In terms of the hoisting mechanism, safety protection devices such as load limiters and hoisting height limiters are also installed to ensure the safety of lifting operations.

Electrical Safety: The electrical system of gantry cranes is designed and installed with full consideration of outdoor environmental factors, using waterproof, dustproof, and moisture-proof electrical equipment and protective measures. Electrical lines are installed in conduits to avoid exposure to water, dust, and moisture. Electrical lines are installed in conduits to prevent exposure and damage. Additionally, comprehensive lightning protection devices are installed to prevent lightning strikes from damaging the electrical system, ensuring safe operation under adverse weather conditions.

(3) Summary of Safety Performance Differences

Overall, both bridge cranes and gantry cranes adhere to strict safety standards and have comprehensive protective measures. However, due to differences in their working environments and structural characteristics, the focus of safety protection measures also varies. Bridge cranes primarily focus on ensuring structural stability and operational precision in indoor environments; gantry cranes, on the other hand, must consider outdoor environmental factors such as wind resistance, lightning protection, and protection against foreign objects that may affect safety performance. In actual use, regardless of the type of crane selected, strict adherence to safety operating procedures, regular safety inspections, and maintenance are essential to ensure the equipment remains in a safe and reliable operational state.

6. Selection Recommendations

(1) Selection Based on Operating Environment

Indoor Environments: If the operating environment is primarily indoor, such as factory workshops or warehouses, and there are high requirements for space utilisation and lifting precision, while the facility has the conditions to install overhead tracks, then a bridge crane is a suitable choice. It can fully utilise indoor space without occupying ground space or obstructing ground traffic, and can achieve precise material handling to meet production process requirements.

Outdoor Environments: For outdoor work scenarios, such as ports, docks, construction sites, and open-air yards, gantry cranes have distinct advantages. Their independent leg structure and ground-based movement allow them to adapt to complex outdoor terrains and environments without relying on building support, enabling free movement in open areas to complete material handling tasks.

(2) Selection based on lifting capacity and lifting height

Lifting capacity: When determining the lifting capacity, factors such as the maximum weight of the actual cargo to be lifted and potential dynamic loads must be considered. If the lifting capacity requirement is relatively small, typically ranging from a few tonnes to several dozen tonnes, both bridge cranes and gantry cranes offer multiple models to choose from. However, if the lifting capacity is large, reaching hundreds of tonnes or more, and high precision is required, bridge cranes are generally more advantageous, as their structural design and manufacturing processes can better meet the demands of large lifting capacities and high-precision lifting operations. For outdoor operations with large lifting capacities, large gantry cranes are the preferred choice, as their robust load-bearing capacity and flexible operational range can handle various large-scale cargo lifting tasks.

Lifting height: The requirement for lifting height also influences crane selection. If the operation requires lifting cargo to a higher position, such as lifting containers to the depths of a ship's hold during port cargo handling, or lifting construction materials to higher floors during high-rise building construction, a crane with a lifting height that meets the requirements must be selected. Generally, gantry cranes offer greater flexibility in terms of lifting height and can be customised to achieve higher lifting heights as needed to accommodate different operational scenarios. In contrast, the lifting height of bridge cranes is primarily limited by the height of the factory building.

(3) Selecting based on budget and cost-effectiveness

Limited budget: If the project budget is limited, the operational duration is short, or there is a high demand for equipment versatility, a gantry crane may be the more economical choice. Its lower initial purchase and installation costs, along with relatively simple maintenance requirements, can meet operational needs while keeping costs in check.

Summary:

Although both bridge cranes and gantry cranes are lifting equipment, their applicable scenarios differ significantly: the former is the ‘mainstay for indoor fixed operations,’ while the latter is the ‘versatile solution for multiple scenarios.’ When selecting, it is essential to consider factors such as the operational environment, load requirements, and budget constraints. Henan Mining Crane has years of design and manufacturing experience and can provide you with a full-process solution from selection to installation, making lifting operations more efficient and safe.