Crane muirearaithe ceithre-girder

Crane muirearaithe ceithre-girder

High-Temperature Lifting Solutions for Electric Arc Furnace (EAF) Charging

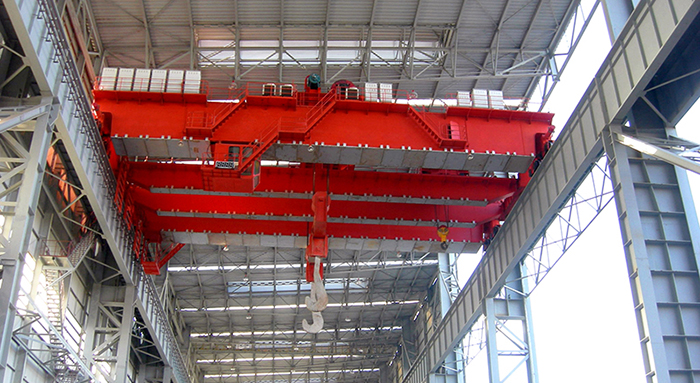

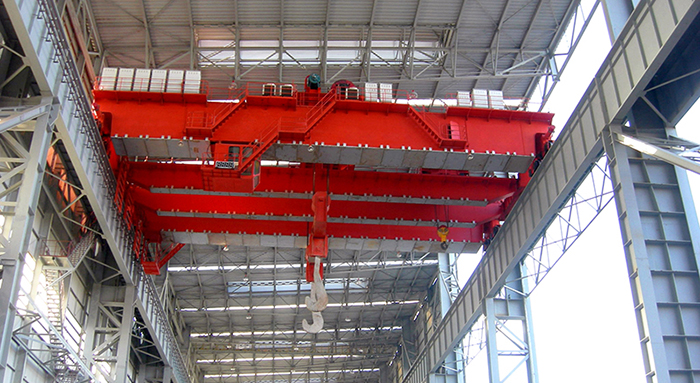

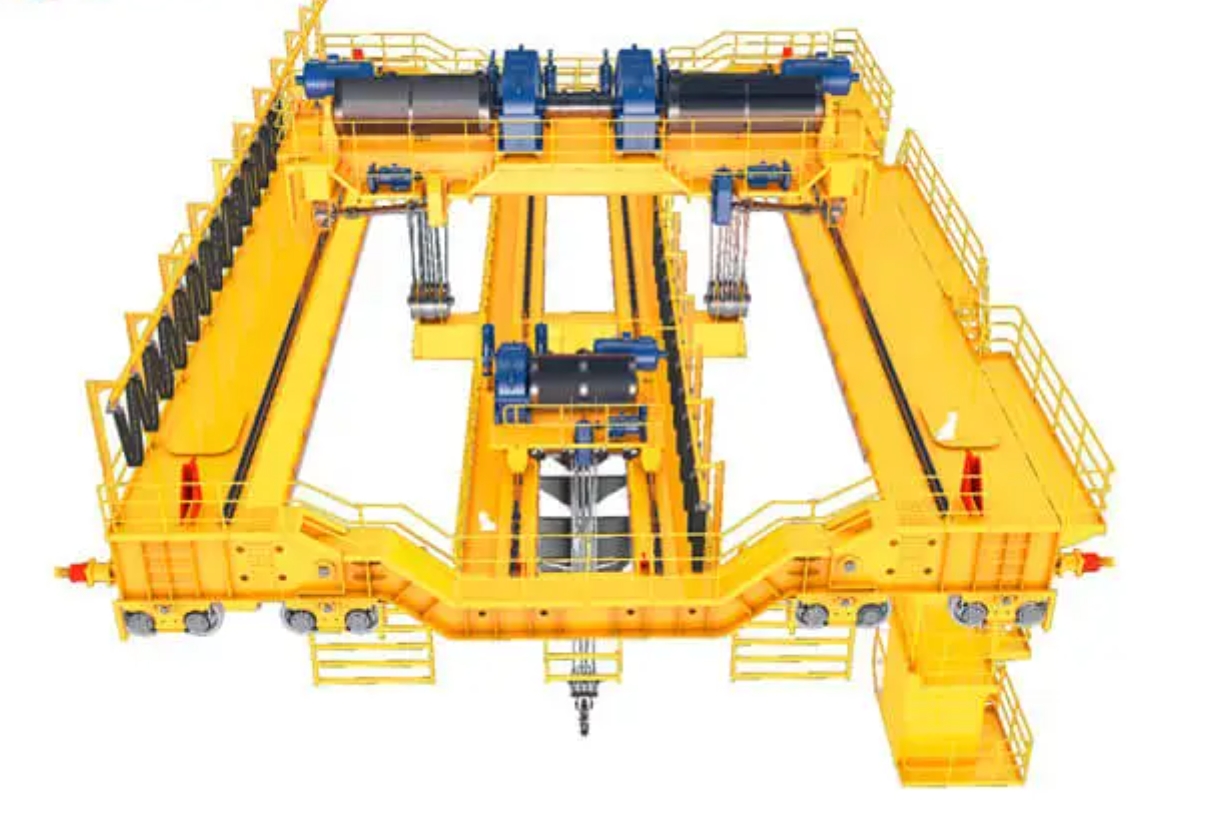

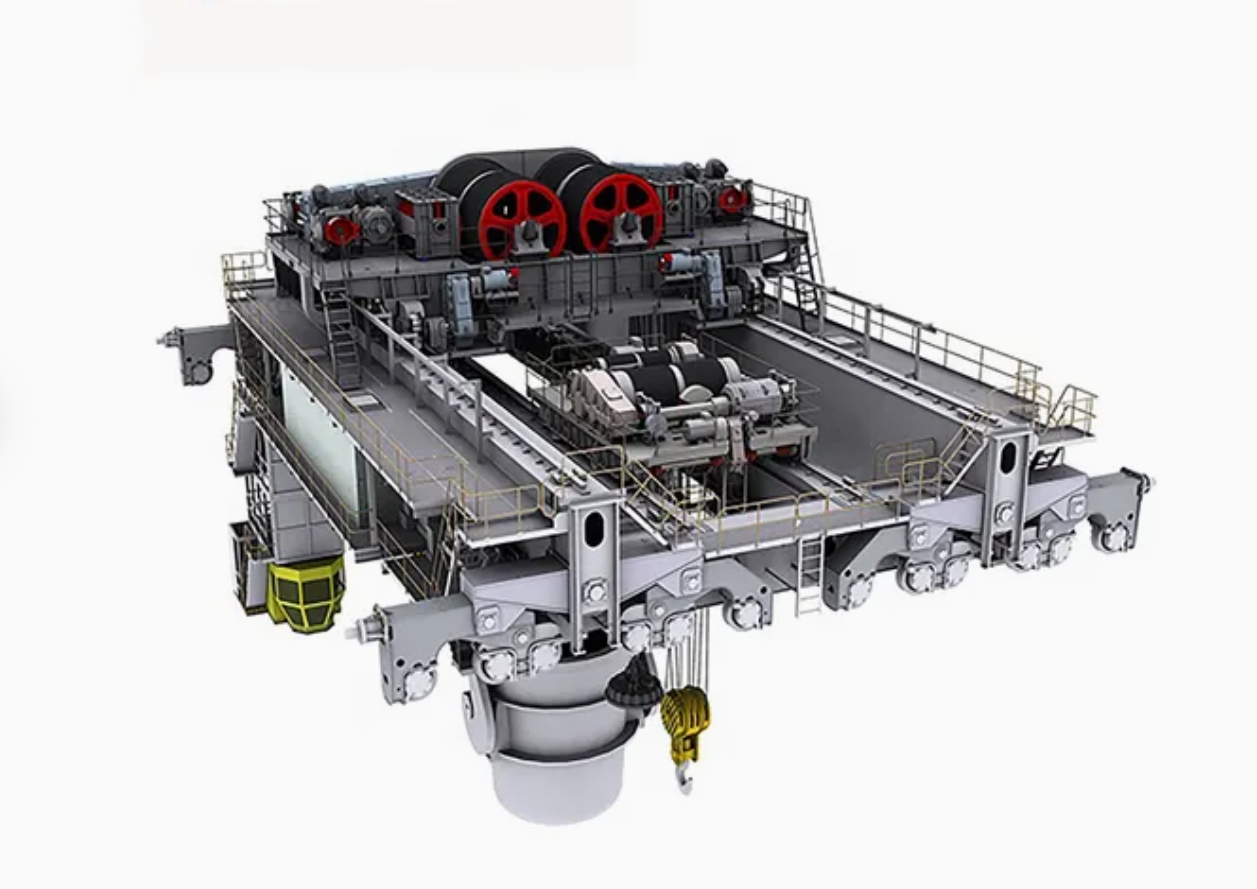

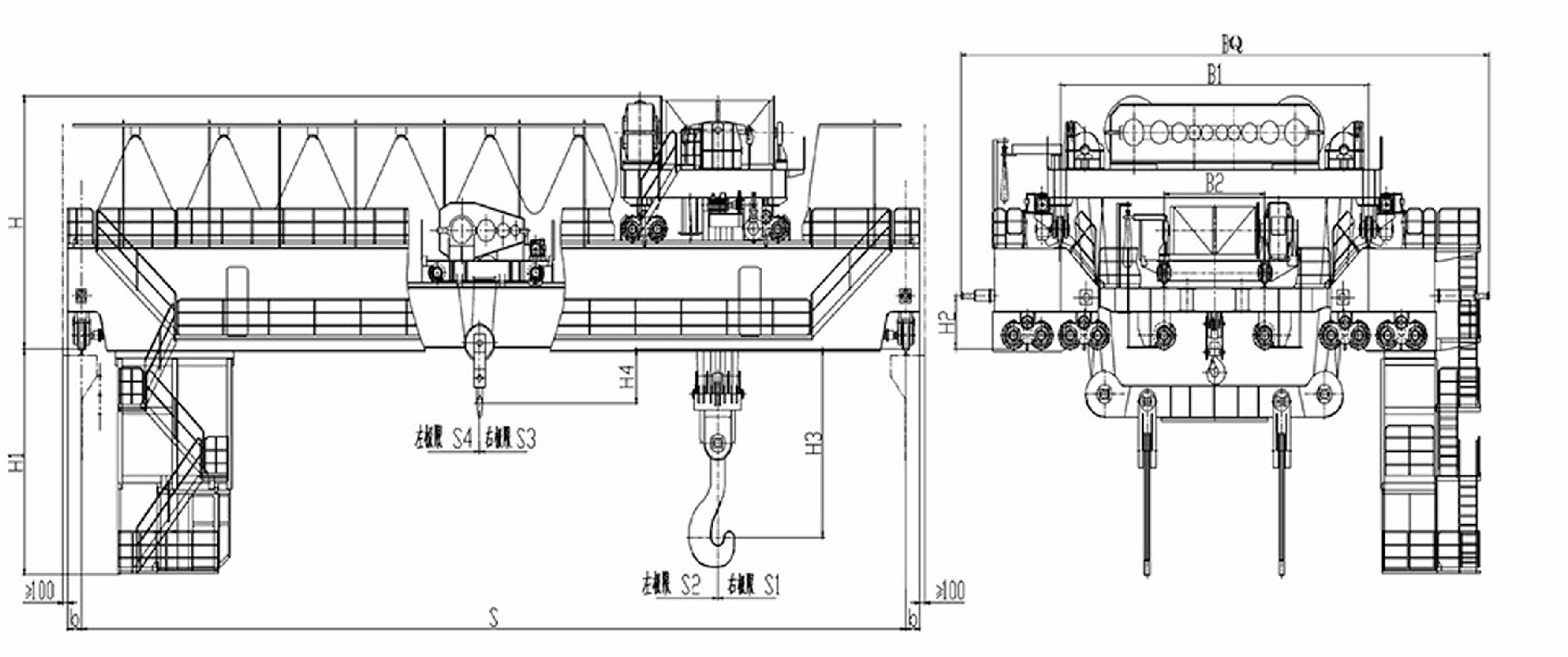

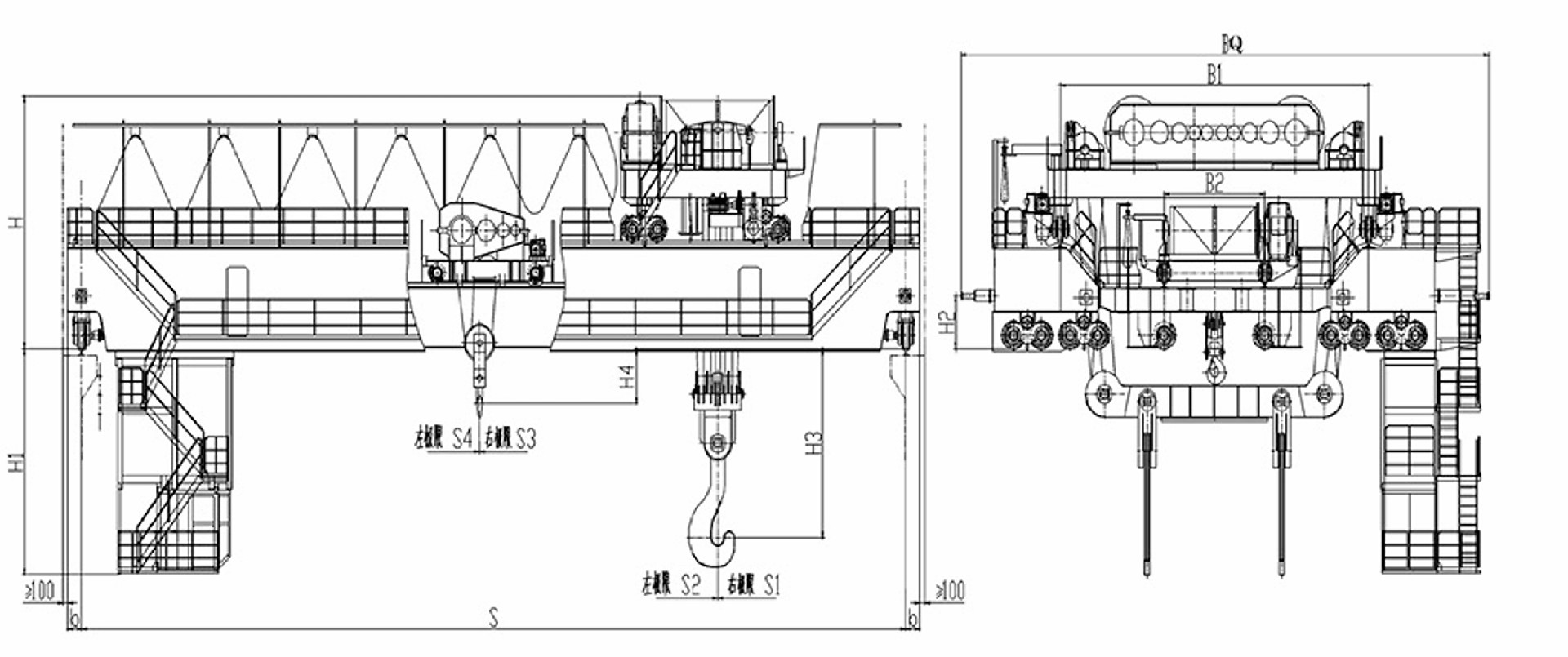

Henan Mine’s charging crane is a core component in steelmaking facilities, purpose-built for feeding electric arc furnaces (EAF) with scrap or molten metal. Designed for continuous operation under extreme heat, this overhead crane is also capable of delivering hot metal to the ladle furnace (LF) or continuous casting machine (CCM). Engineered with a four-girder configuration, it provides exceptional stability, lifting accuracy, and long service life.

I go leor gléasraí, feidhmíonn an crann seo mar chúltaca freisin do chráin láimhseála ladle, ag cinntiú leanúnacht táirgthe i gcásanna ríthábhachtacha.

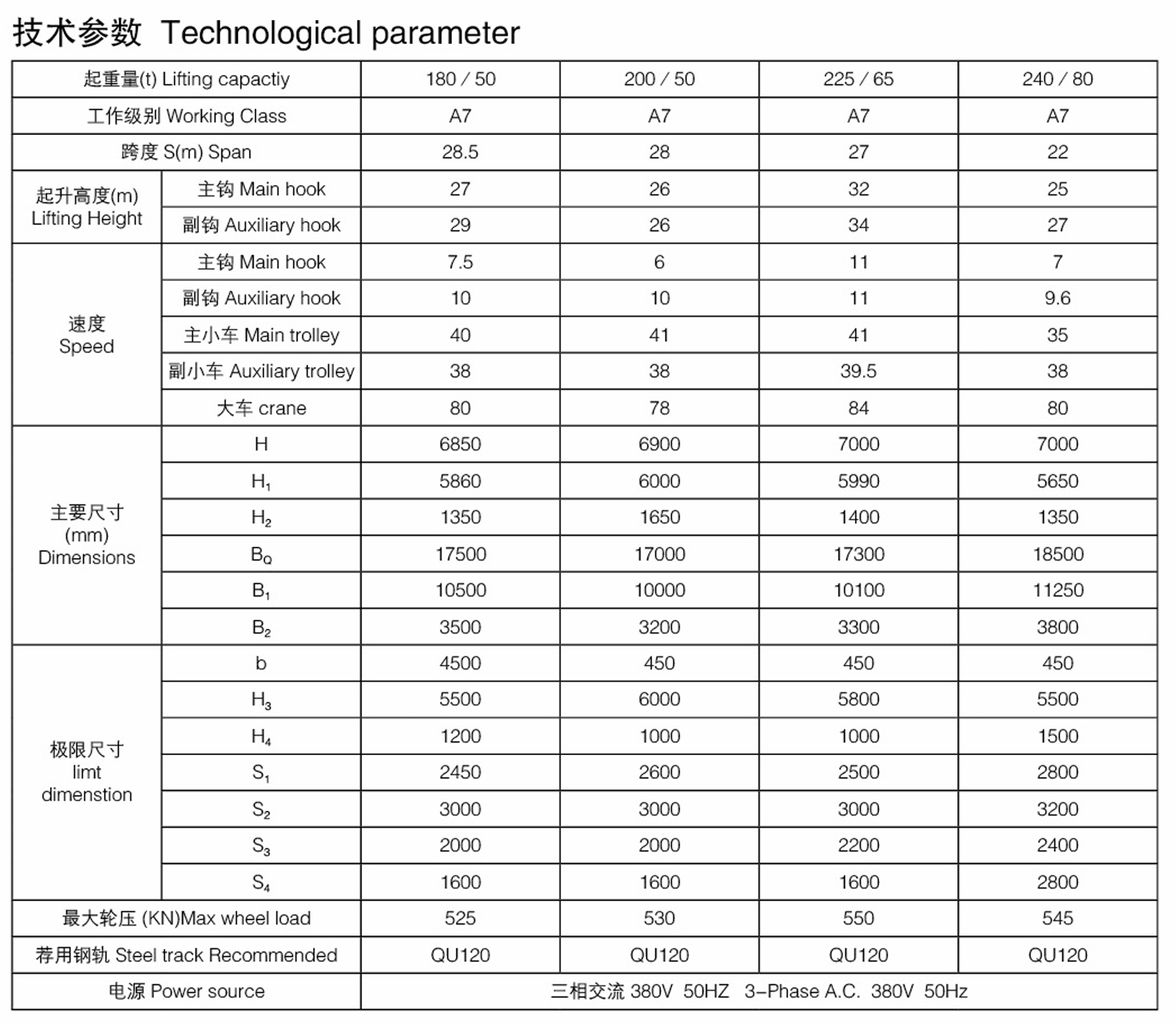

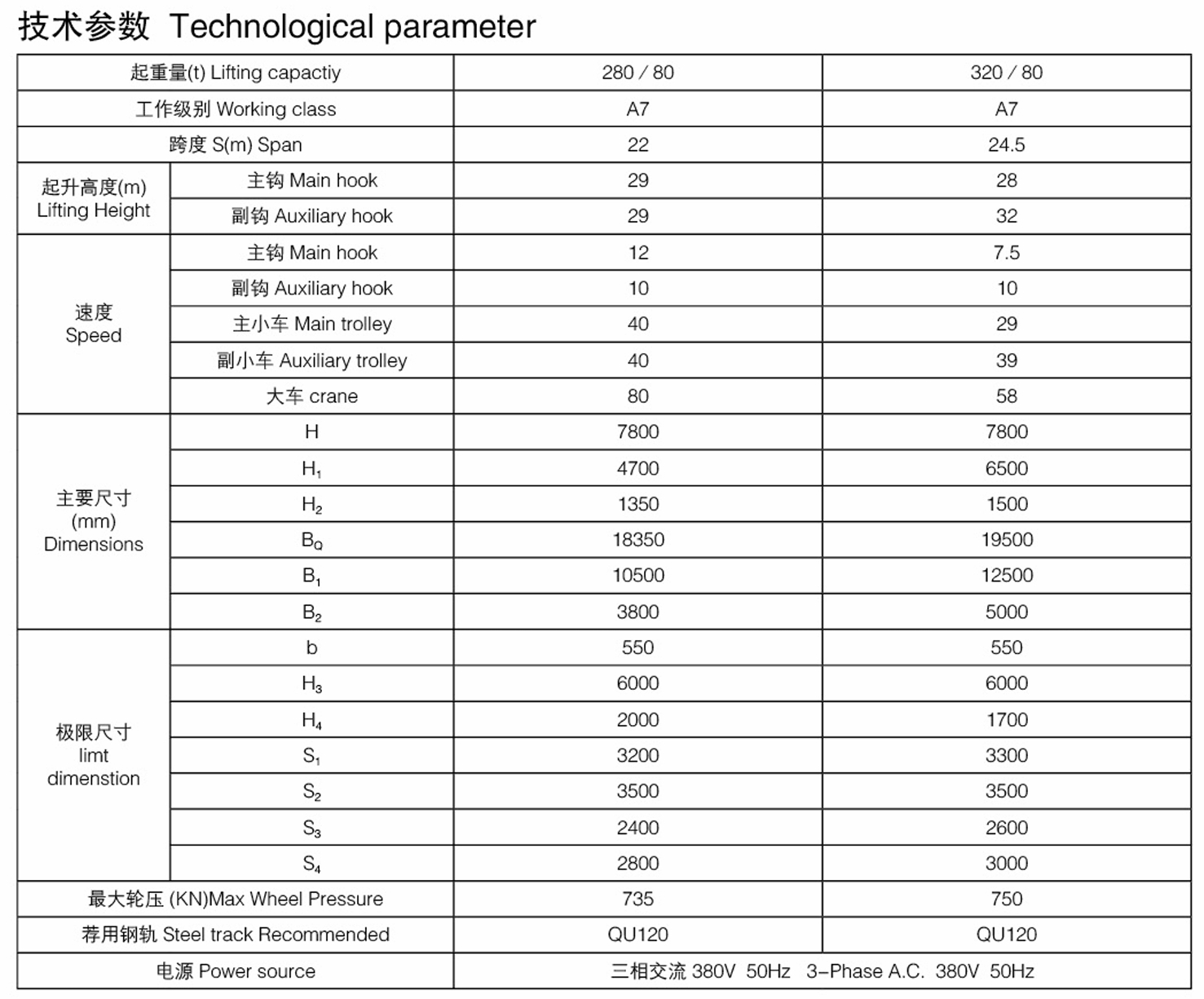

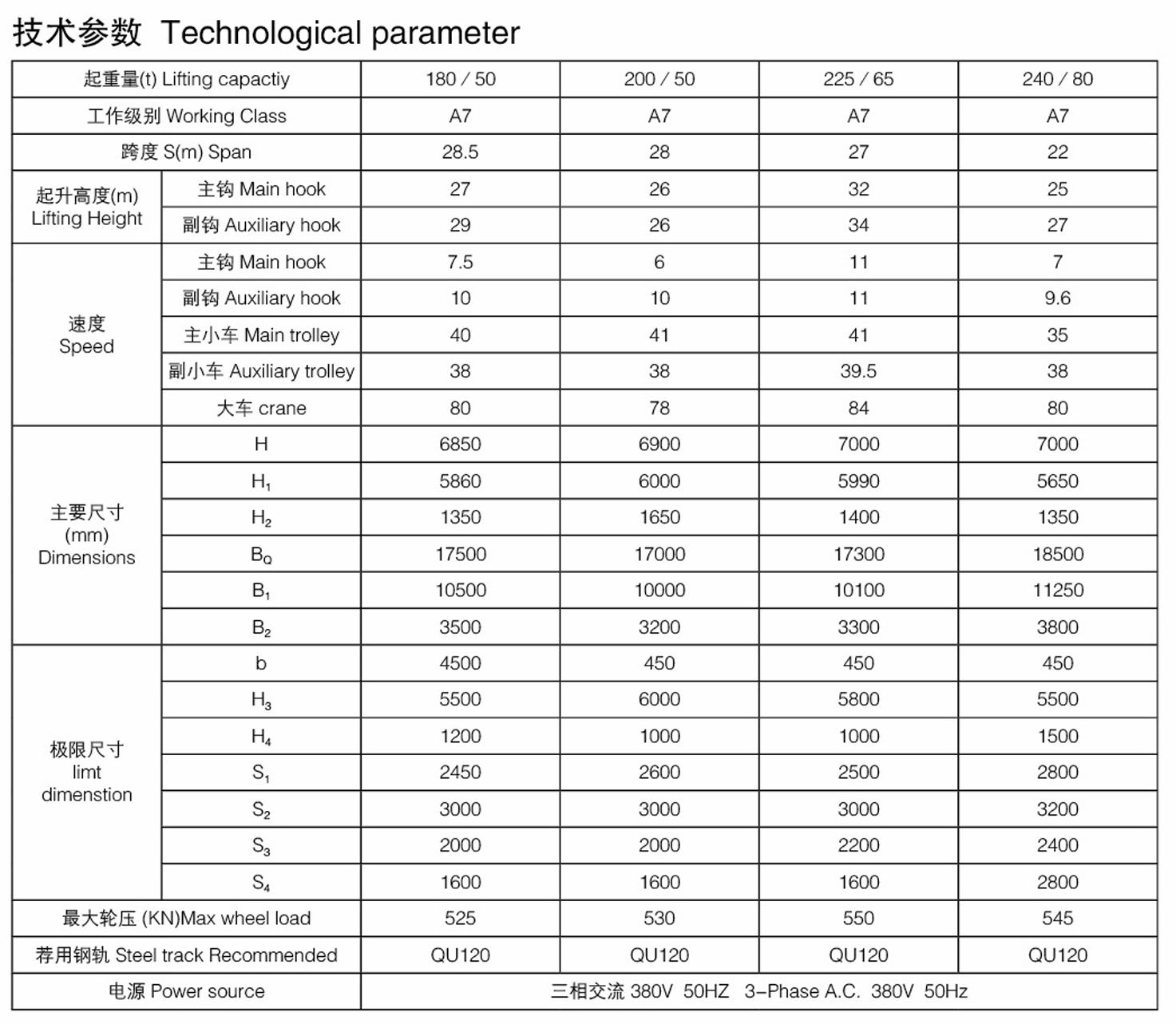

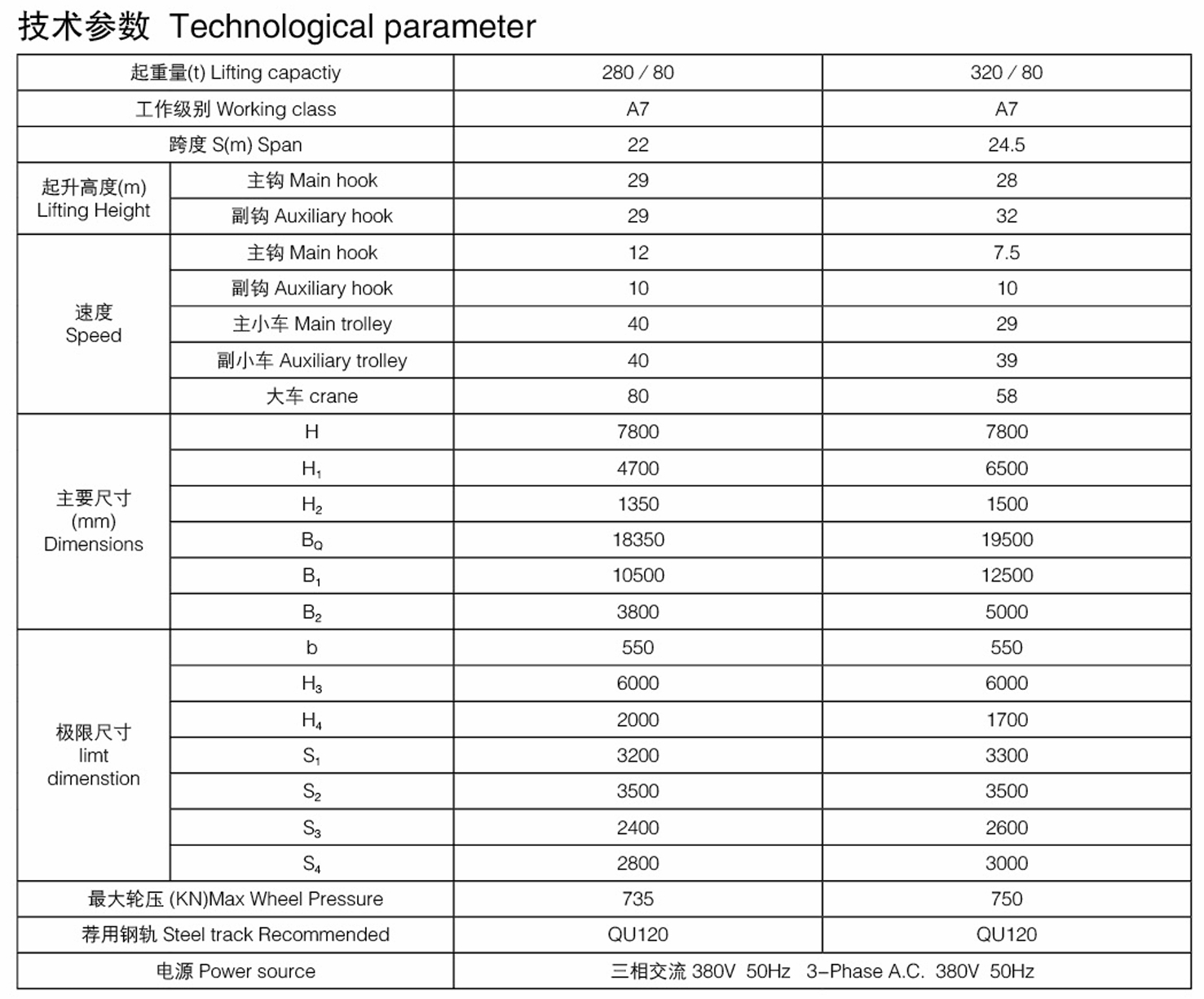

| Paraiméadar | Luach / Raon |

| Cineál Crane | Crane muirearaithe thar ceann |

| Dearadh Struchtúrtha | Ceithre-Girder le Trolleys Twin |

| Cumas ardaithe | Up to 500 tons (customized) |

| Meicníocht ardaithe | Trolley dúbailte le tiomáint sioncrónaithe |

| Timpeallacht Iarratais | Teas ard, miotail leáilte, dualgas 24/7 |

| Cosaint Teasa | Inslithe teirmeach, scáth lasaí |

| Soláthar Cumhachta | AC 3-chéim, voltas saincheaptha |

| Córas Rialaithe | Cabin + Optional Remote |

| Iontrálaíocht | Brac cúltaca, tiománaí dúbailte, teorainneacha |

| Deimhniú | GB / ISO / CE-chomhlíonta |

Líon an fhoirm thíos isteach chun rochtain láithreach a fháil ar chatalóg na gcráin agus labhair lenár bhfoireann theicniúil le haghaidh athmholadh