Aluminium Coil Elektresch Transfer Cart System

Aluminium Coil Elektresch Transfer Cart System

Präzisiounstransport fir Coil Handling Entwéckelt vun Henan Mine

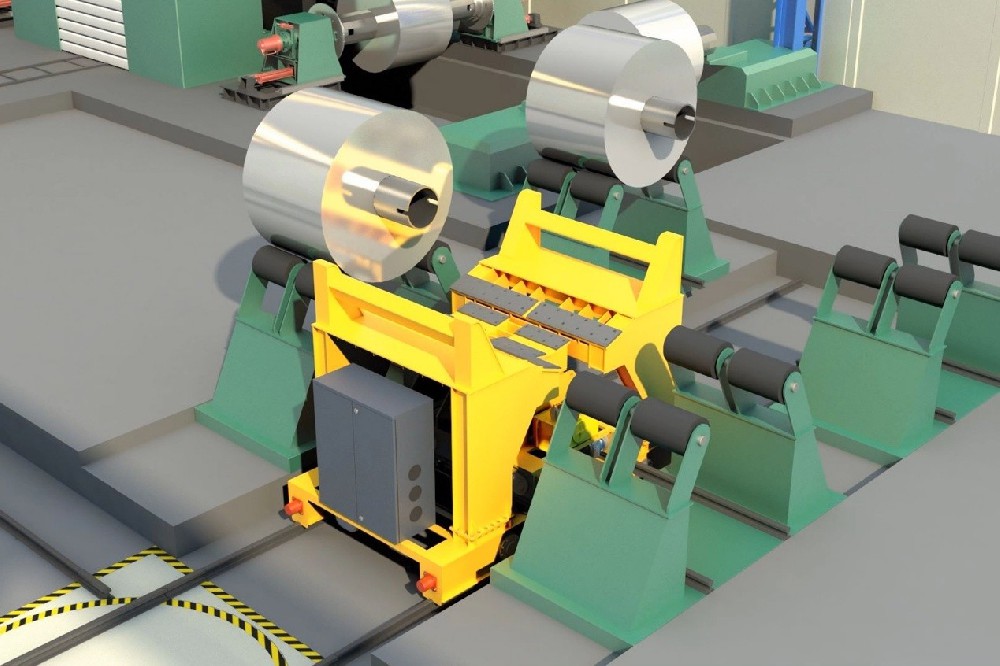

D'Aluminium Coil Electric Transfer Cart System aus Henan Mine ass eng voll integréiert Spulentransportléisung entwéckelt fir de spezifesche Besoine vun Aluminiumveraarbechtungsanlagen a Walzmachinen gerecht ze ginn. Gebaut fir d'Spulenbewegung ze rationaliséieren, d'Handhabungsrisiken ze reduzéieren an de Produktiounsfluss ze verbesseren, spillt dëse System eng Schlësselroll bei der Moderniséierung vun der Aluminiumspulenlogistik.

Mat enger Elteren-Kand-Wagen-Konfiguratioun garantéiert dëse System e séchere, präzise an automatiséierte Transport vu fäerdege Aluminiumspulen tëscht Produktiounslinnen, Pufferlagerberäicher an Versandzonen. Egal ob et an enger neier automatiséierter Ariichtung installéiert ass oder an eng existent Atelier ëmgebaut ass, et liwwert d'Operatiounskontinuitéit an de Materialschutz an all Etapp.

| Systemkonfiguratioun:Elteren Wagen | Mounted on rails, with saddle + conveyor system;Child Cart |

| Liftkapazitéit | 5 – 60 tons (customizable per coil weight and dimensions) |

| Reesgeschwindegkeet | Up to 60 m/min (adjustable via frequency inverter) |

| Positiounsgenauegkeet | ±2 mm mat sensorbaséierter Ausrichtung |

| Typ vun der Spur | Embedded Steel Rail oder overhead-guided Line |

| Drive Typ | Electric motor + gear reducer with soft-start control |

| Stroumversuergung | Cable drum / low-voltage rail / battery (site-dependent) |

| Sécherheetssystemer | Hindernisser Detektioun, Iwwerlaaschtungsschutz, Noutstop |

| Konformitéit | ISO, GB, CE-zertifizéiert Komponenten |

Füllt de Formulaire hei ënnen aus fir direkt Zougang zum Krankatalog ze kréien an schwätzt mat eisem technesche Team fir Rekommendatiounen