Isoléiert Fütterungskran fir elektrolytescht Aluminium

Isoléiert Fütterungskran fir elektrolytescht Aluminium

Entworf vun Henan Mine Sécher, präzis, a gebaut fir haart Ëmfeld

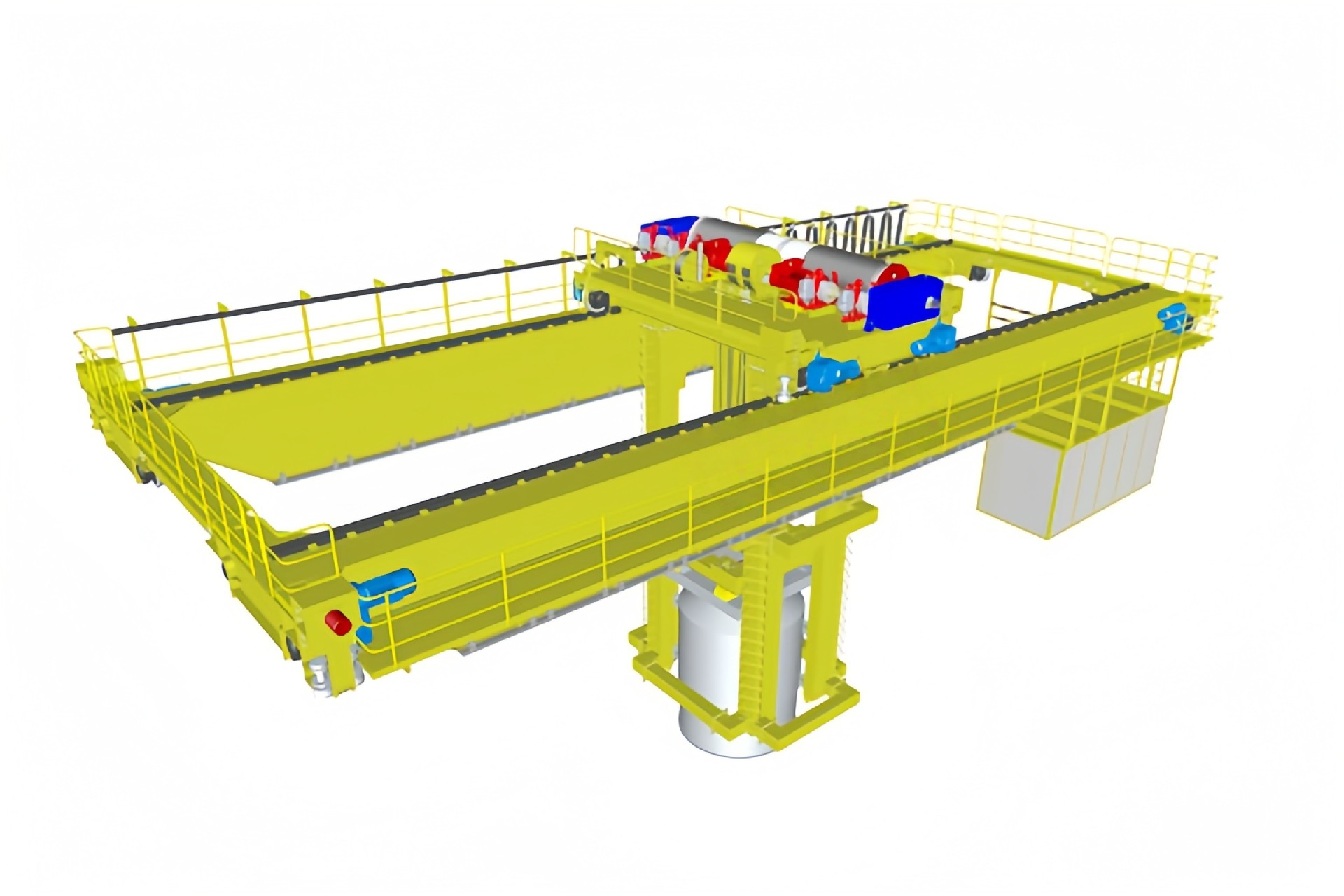

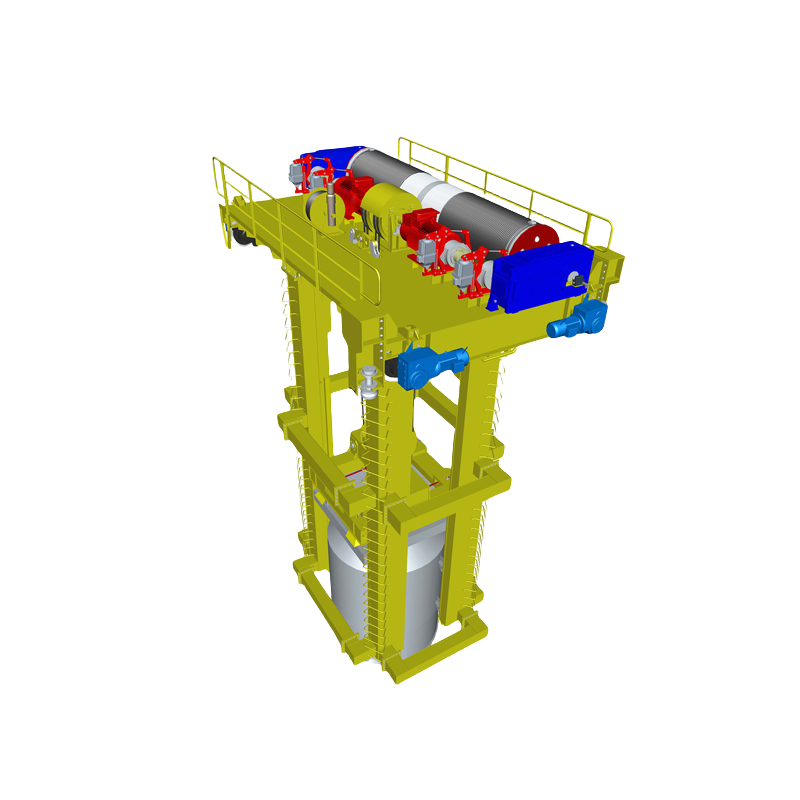

D'Henan Mine Isoléiert Feeding Overhead Crane ass e fortgeschratt Heftsystem, speziell fir d'elektrolytesch Aluminiumindustrie entwéckelt, wou extrem Betribsbedingungen - wéi héich Temperatur geschmolzen Salz, schwéiere Stroum, staark Magnetfelder a korrosiv Atmosphären - héich spezialiséiert Léisungen erfuerderen.

Dëse Kran kombinéiert Héichspannungsisolatiounstechnologie, anti-magnetesche Design an e speziellen Fütterungstrolley; fir Schlësselproduktiounsaufgaben auszeféieren, dorënner Aluminiumfluorid-Fütterung, geschmolzene Aluminiumextraktioun, Handhabung vun der Zellstruktur a méi. Vertrauen vun Top Aluminiumproduzenten, spillt et eng zentral Roll fir kontinuéierlech, sécher an automatiséiert Operatiounen ze garantéieren an der Schmelzplanter.

| Nominale Liftkapazitéit | Custom-configured (typically 10–74 tons) |

| Krankonfiguratioun | Dräi-Beam, dräi-Trolley Layout |

| Speziell Trolleys | Tool Trolley (hook-type lifting);Aluminum Extraction Trolley (with insulated, anti-sway hook & weighing system);Feeding Trolley (with hopper, discharge system & electronic measuring unit) |

| Reesmechanismus | 8-Rad, Dual-Drive mat Schaft-montéierte 3-an-1 Reduktoren |

| Kontrollmodus | Cabin control + remote diagnostics |

| Ëmweltbeständegkeet | Anti-corrosion materials + sealed electronics |

| Operateur Kabin | Ausgestattet mat industrieller HVAC fir extrem Temperaturbedingungen |

| Sécherheetsnormen | GB, ISO, CE-konform |

Füllt de Formulaire hei ënnen aus fir direkt Zougang zum Krankatalog ze kréien an schwätzt mat eisem technesche Team fir Rekommendatiounen