Quatro vigas guindaste de carregamento fundido

Quatro vigas guindaste de carregamento fundido

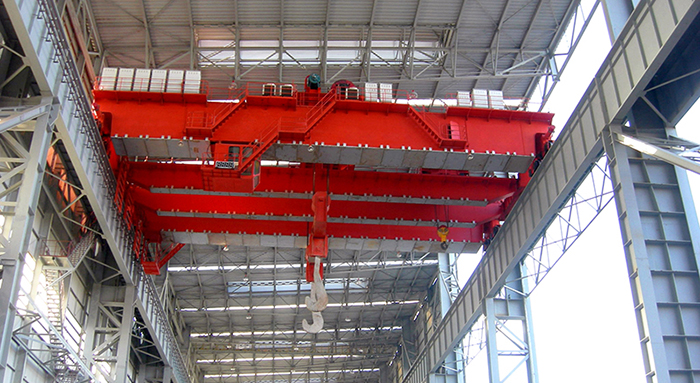

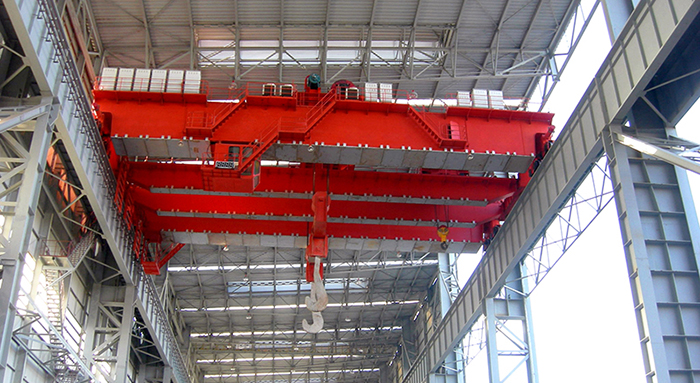

High-Temperature Lifting Solutions for Electric Arc Furnace (EAF) Charging

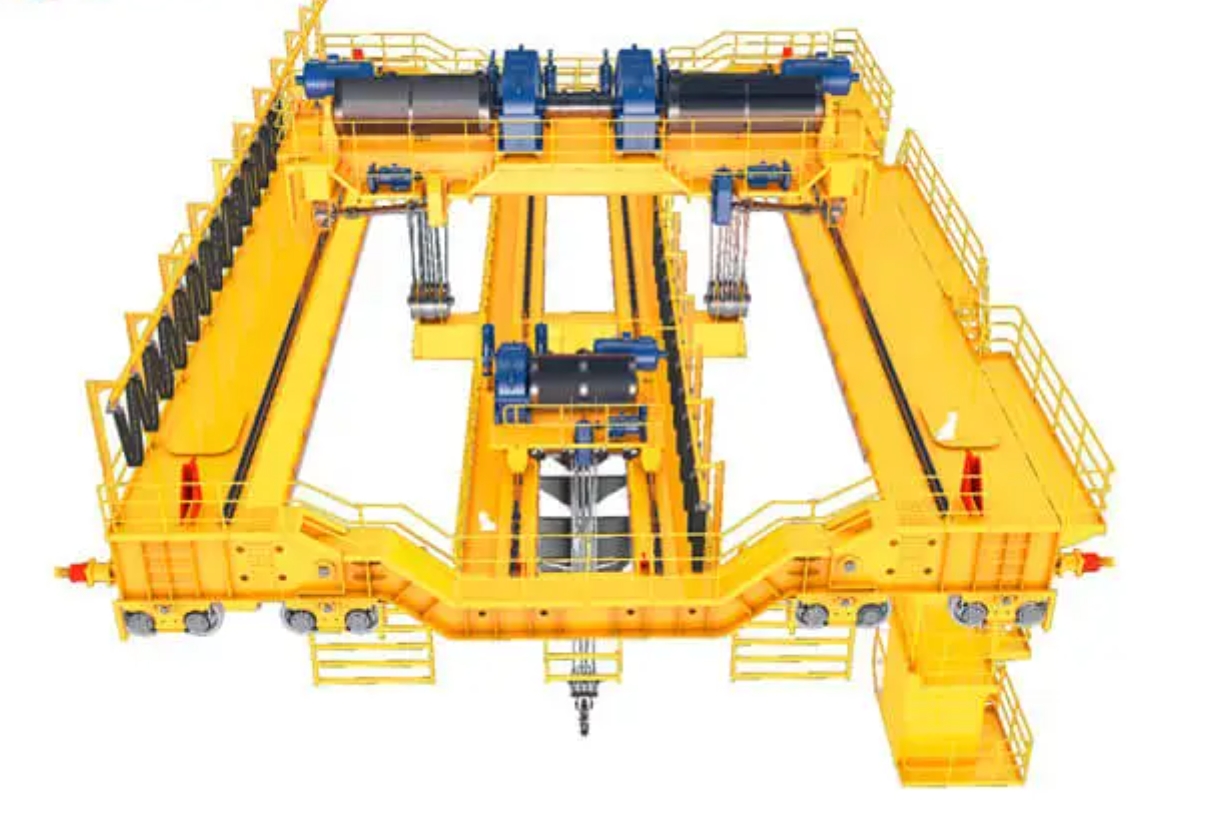

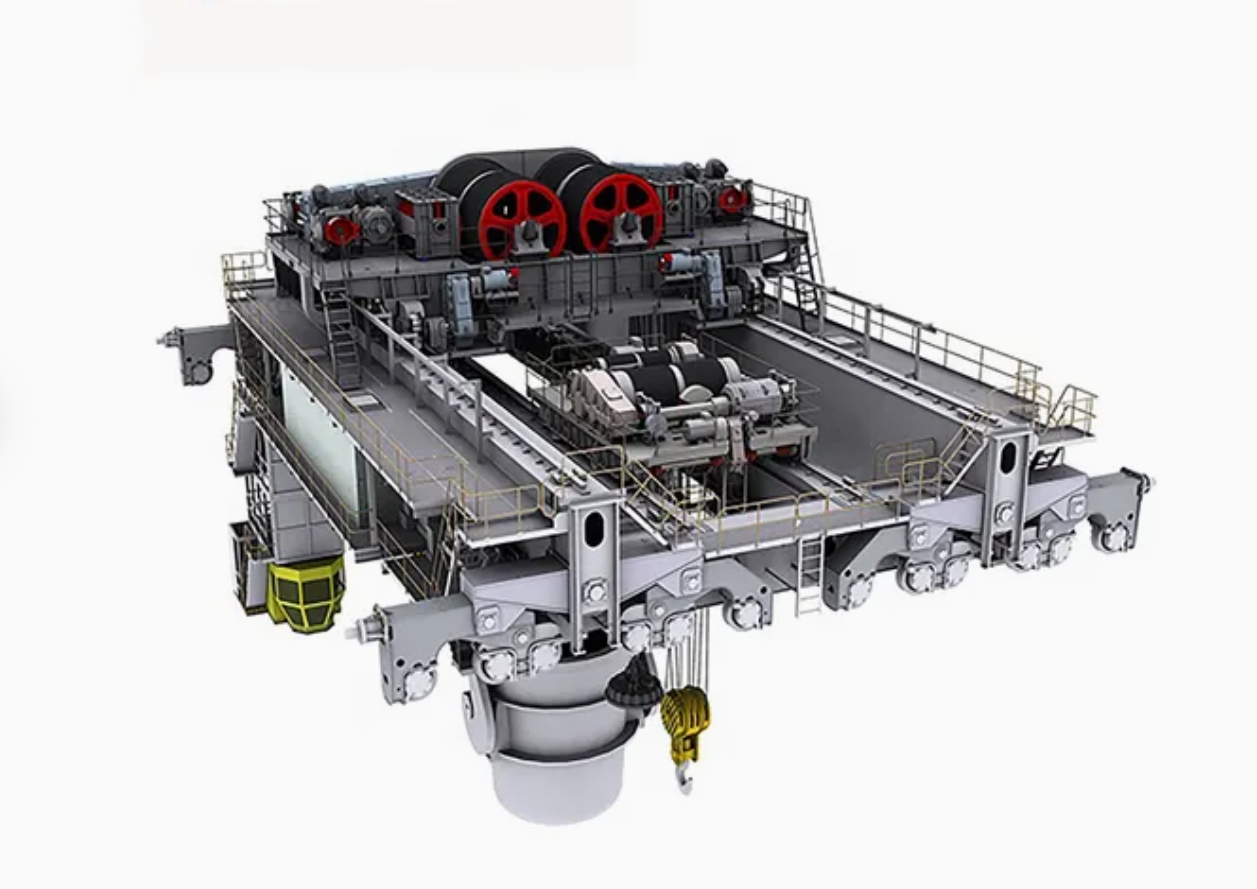

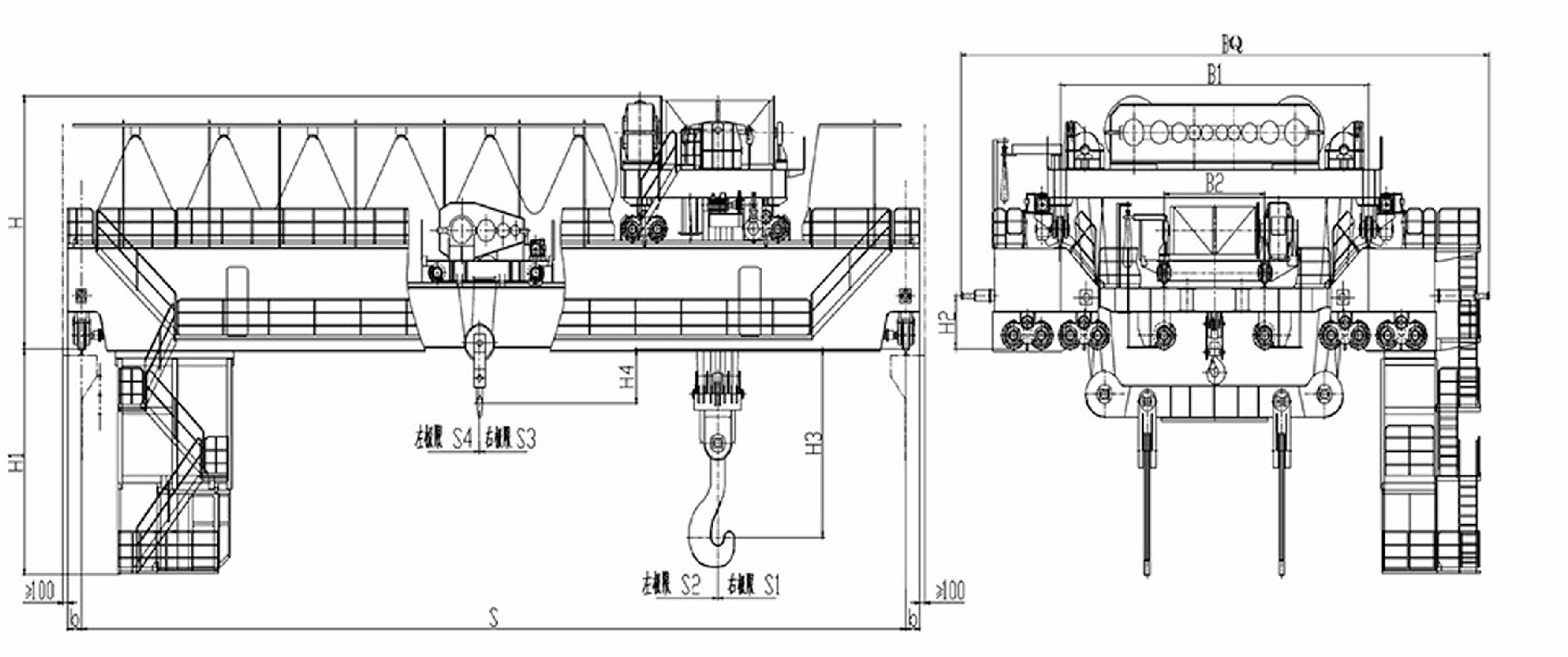

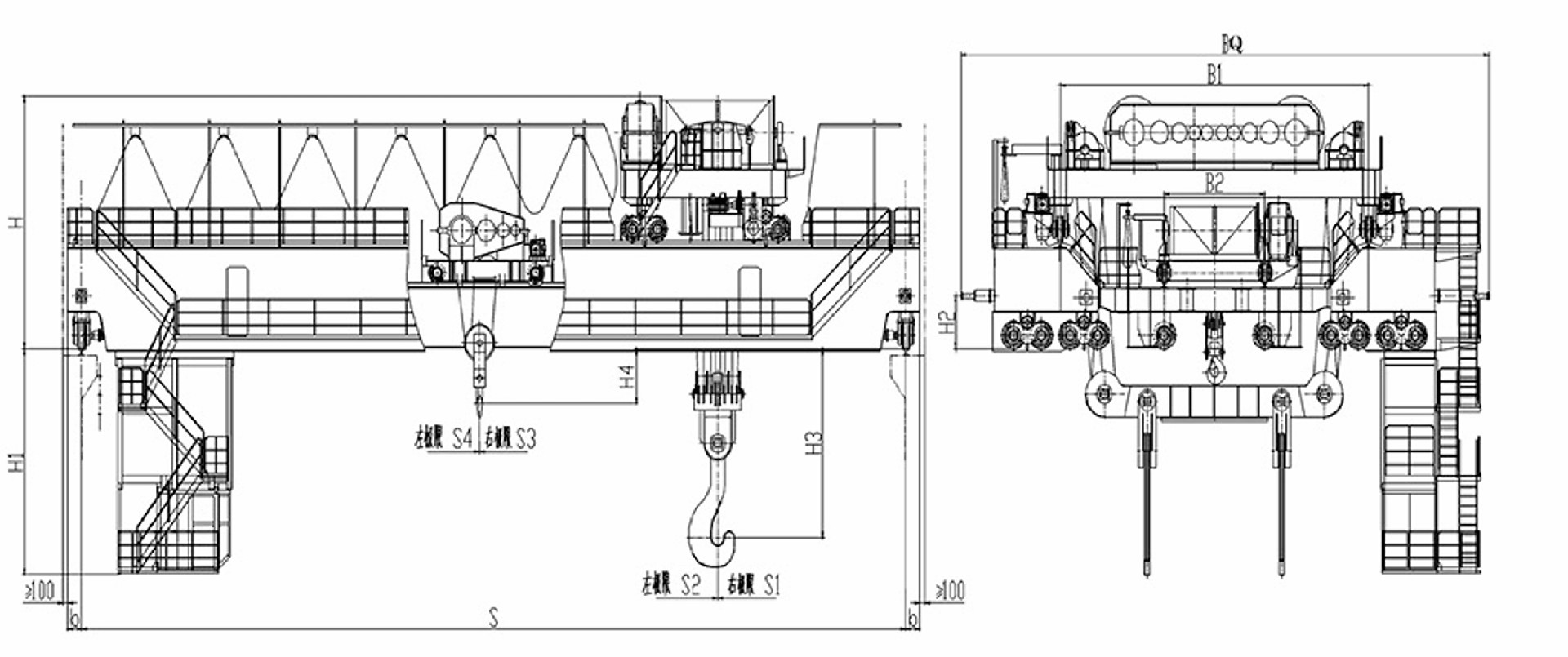

Henan Mine’s charging crane is a core component in steelmaking facilities, purpose-built for feeding electric arc furnaces (EAF) with scrap or molten metal. Designed for continuous operation under extreme heat, this overhead crane is also capable of delivering hot metal to the ladle furnace (LF) or continuous casting machine (CCM). Engineered with a four-girder configuration, it provides exceptional stability, lifting accuracy, and long service life.

Em muitas fábricas, esta guindaste também serve como backup para guindastes de manuseio de palha, garantindo a continuidade da produção em cenários críticos.

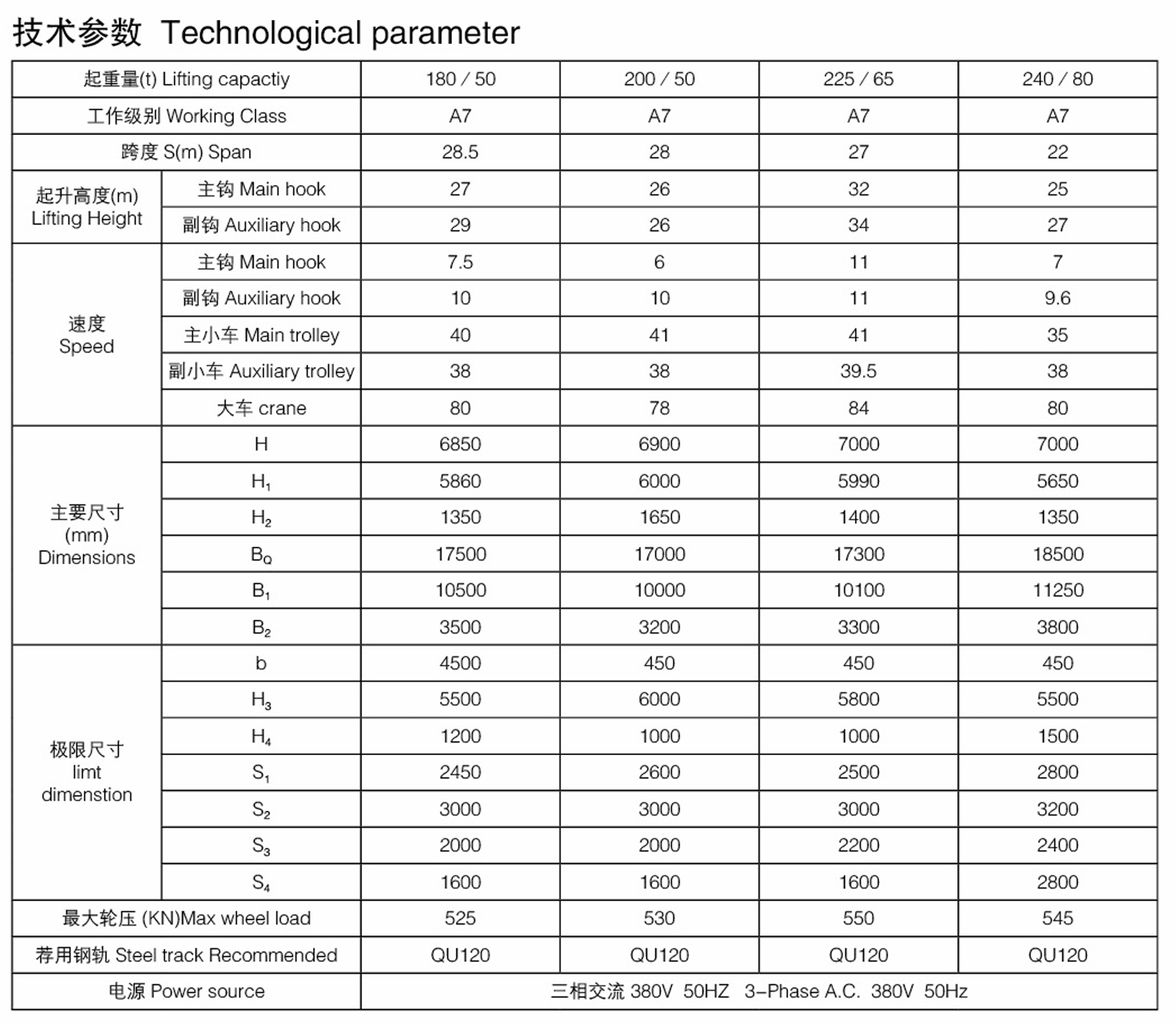

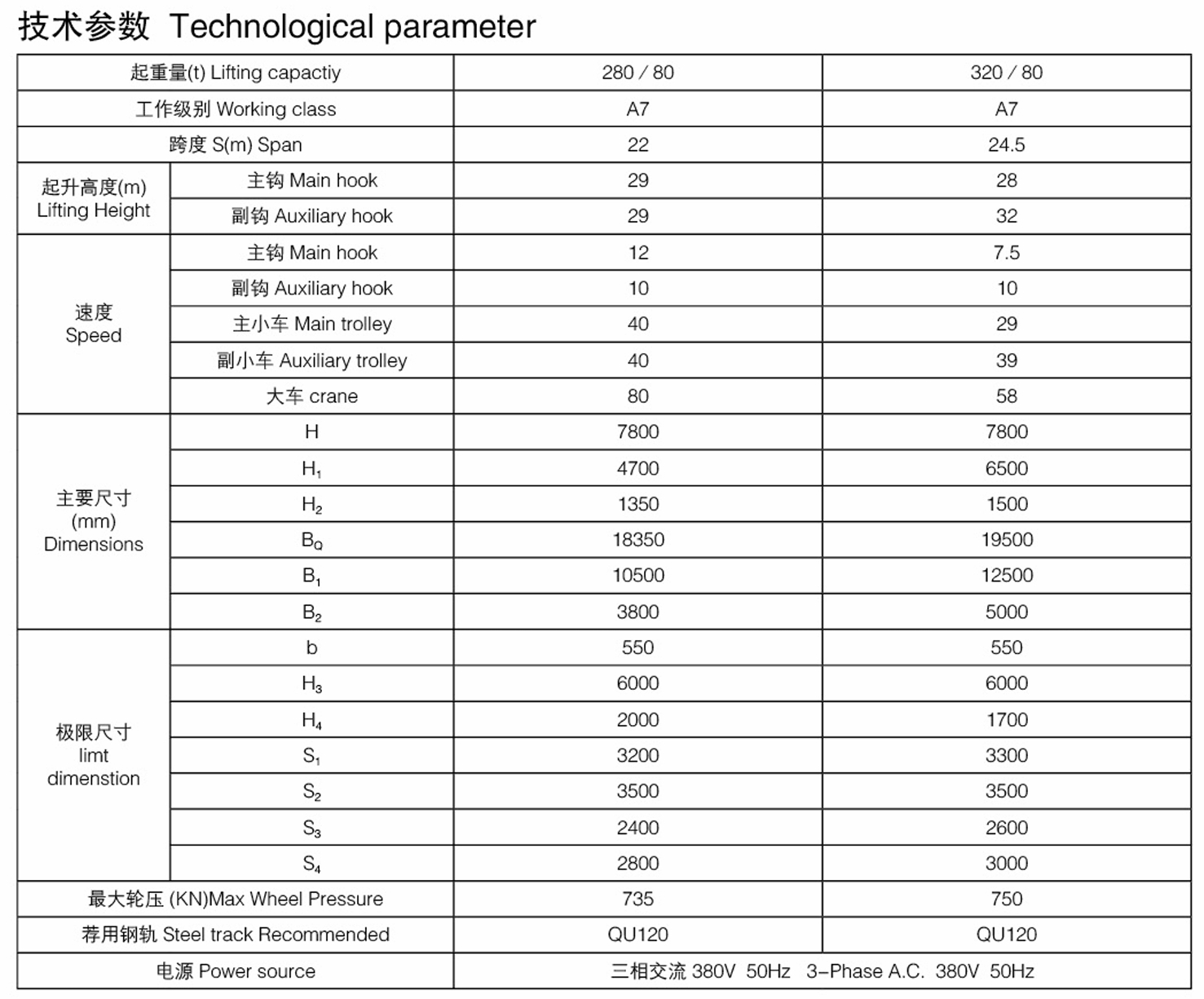

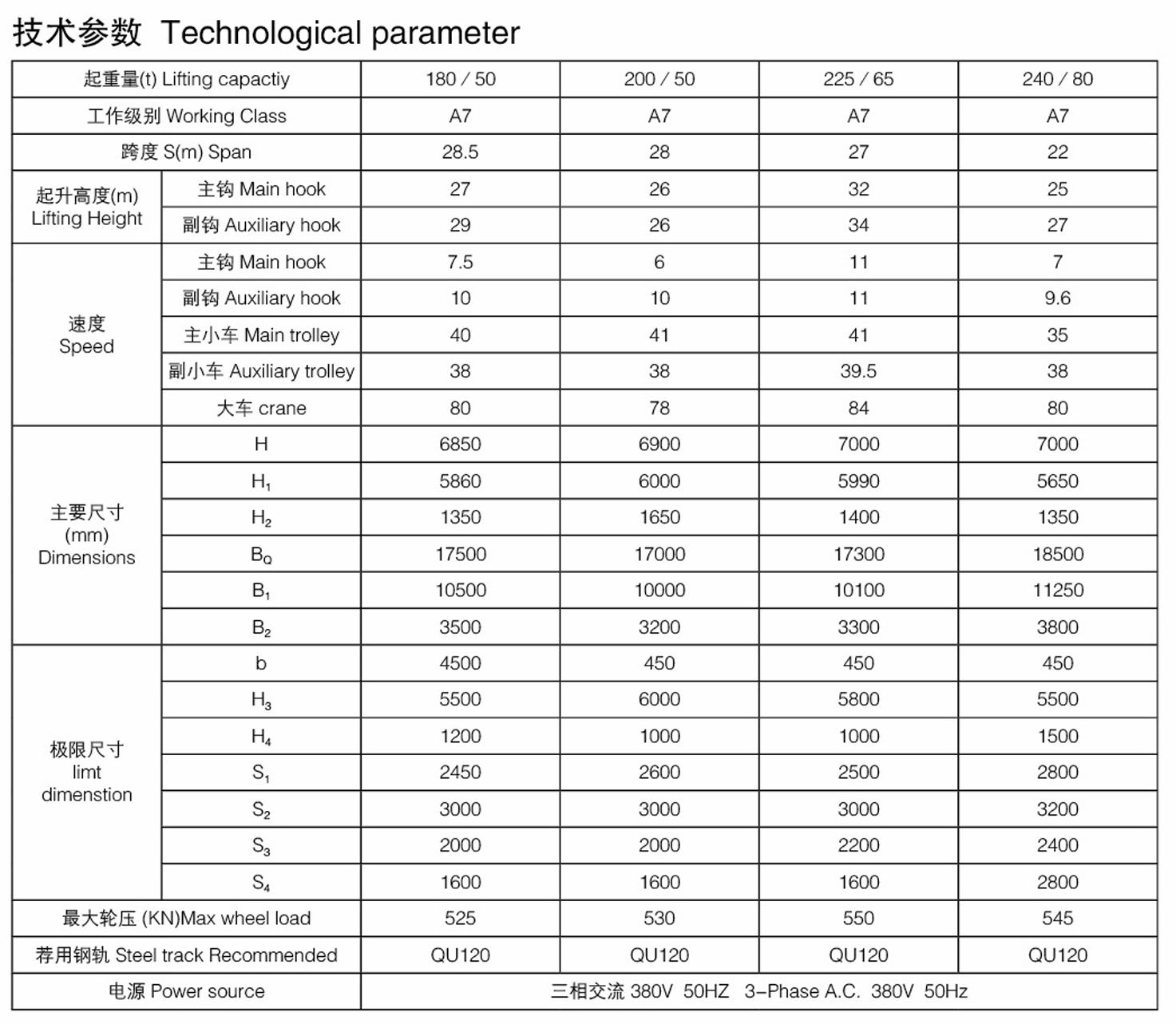

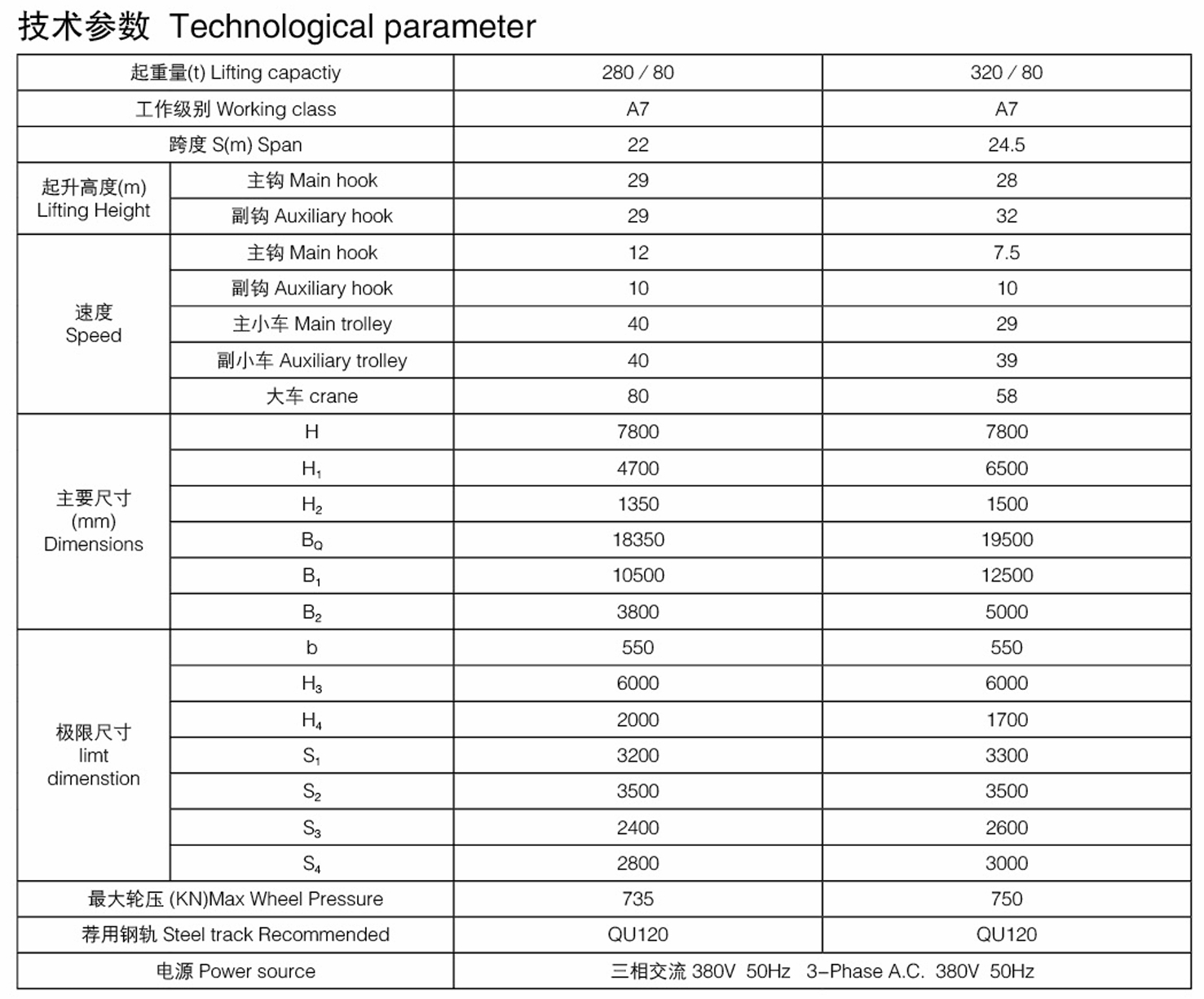

| Parâmetro | Valor / Intervalo |

| Tipo de guindaste | guindaste carregamento overhead |

| Projeto Estrutural | Quatro vigas com carrinhos gêmeos |

| Capacidade de elevação | Up to 500 tons (customized) |

| Mecanismo de elevação | Dual-carrinho com acionamento sincronizado |

| Aplicação Ambiente | Alto calor, metal fundido, serviço 24/7 |

| Proteção térmica | Isolamento térmico, blindagem contra chamas |

| Fonte de alimentação | AC de 3 fases, tensão personalizada |

| Sistema de Controle | Cabin + Optional Remote |

| Redundância | Freio de reserva, transmissões duplas, limiteres |

| Certificação | GB / ISO / CE-conforme |

Preencha o formulário abaixo para obter acesso instantâneo ao catálogo de guindastes e fale com nossa equipe técnica para recomendações