Aluminum Coil električni sistem karticala

Aluminum Coil električni sistem karticala

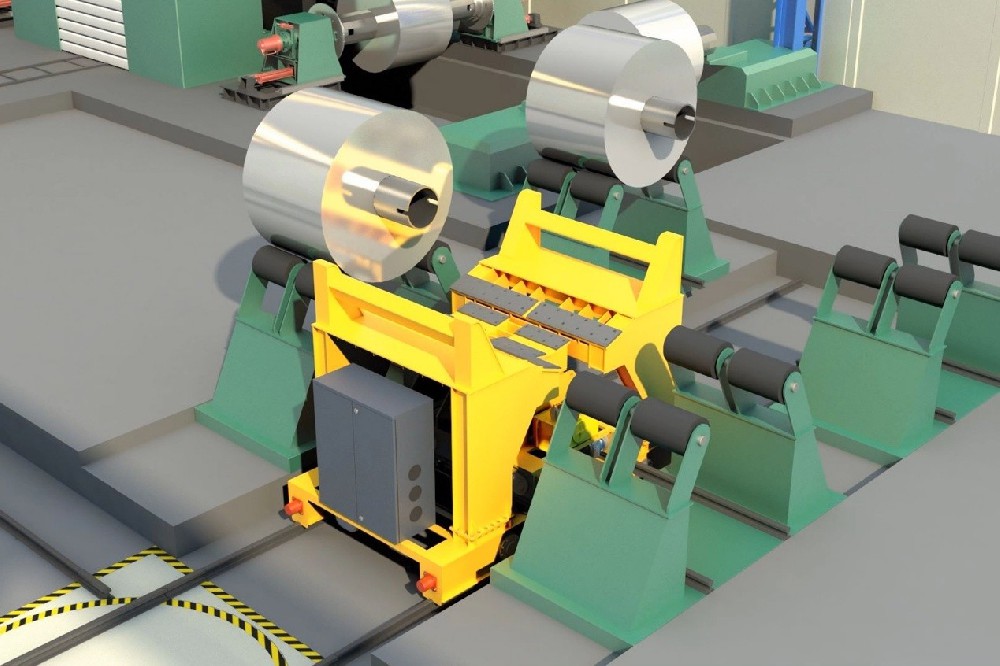

Precizion Transport za rušenje koleja – Enginovan od Henan Mine

Sistem karticama aluminijumskih kolejnih električnih prebacivanja iz Henan Mine nbsp; je potpuno integrisano rješenje kolača, dizajnirano da ispuni specifične potrebe biljaka aluminijuma za procesiranje i svijetlo. Ukrađen na streamliniranje pokreta koline, smanjuje rizike za rukovanje i poboljša tok proizvodnje, ovaj sistem igra ključnu ulogu u modernizaciji aluminijumske ložice.

Na kojem se pružaju konfiguracija roditelja i deteta, ovaj sistem osigurava bezbjednu, tačnu, i automatsku prijevoz kompletnih aluminijumskih kolača između linija proizvodnje, oblasti skladišta bufera i zone prijenosa. - Da li se instalira u novoj automatskoj fabrici ili se obnovila u postojeću radionici, isporučuje operativnu kontinuitet i materijalnu zaštitu na svakoj fazi.

| Konfiguracija sistema:Roditeljska karta | Mounted on rails, with saddle + conveyor system;Child Cart |

| Povraćanje kapaciteta | 5 – 60 tons (customizable per coil weight and dimensions) |

| Brzina putovanja | Up to 60 m/min (adjustable via frequency inverter) |

| Precisitet položaja | ±2 mm sa poravnanjem na osnovu senzora |

| Tip traga | Uhvaćena čelična željeznica ili prevodena linija |

| Tip vožnja | Electric motor + gear reducer with soft-start control |

| Sposobnost moći | Cable drum / low-voltage rail / battery (site-dependent) |

| Sistemi bezbednosti | Otkriće nasilja, zaštita prekopterećenja, zaustavljanje hitnih slučajeva |

| Suosjećanja | ISO, GB, sertifikovane komponente CE |

Napunite u obliku ispod kako bi dobili instant pristup katalogu crane i razgovarali sa našim tehničkim tim za rekomenacije