Štyri-nosník Cast nabíjací žeriav

Štyri-nosník Cast nabíjací žeriav

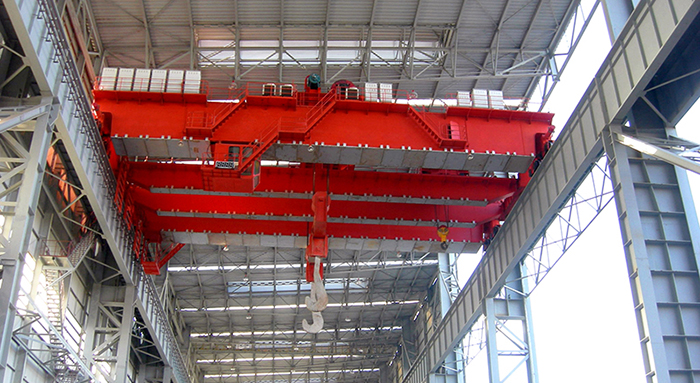

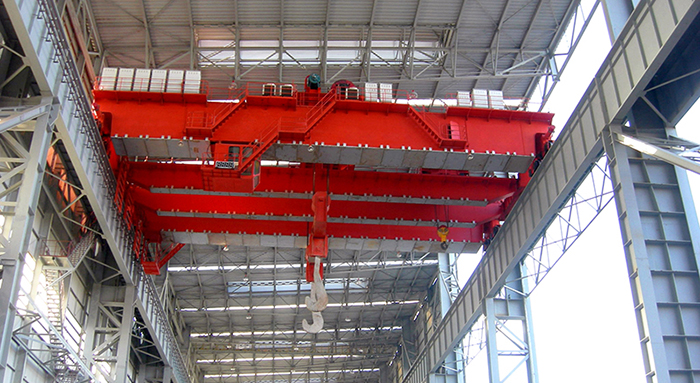

High-Temperature Lifting Solutions for Electric Arc Furnace (EAF) Charging

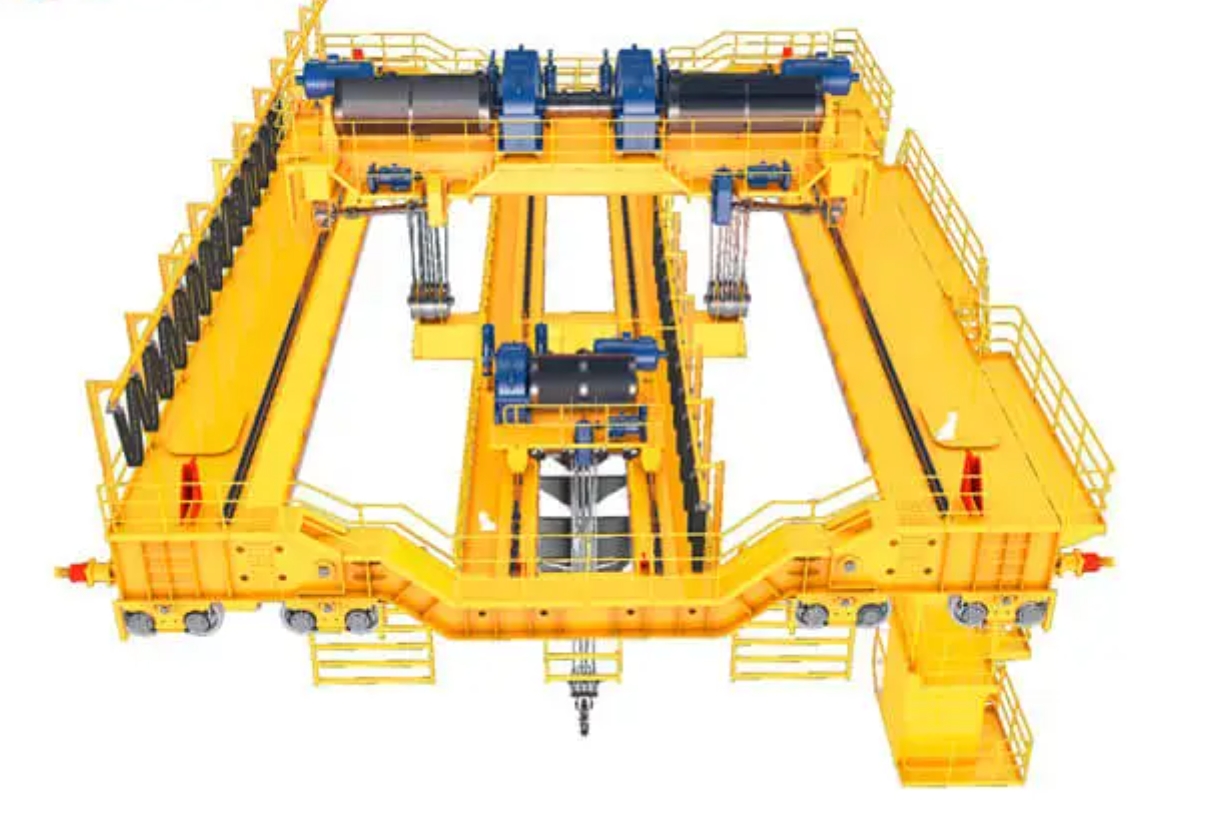

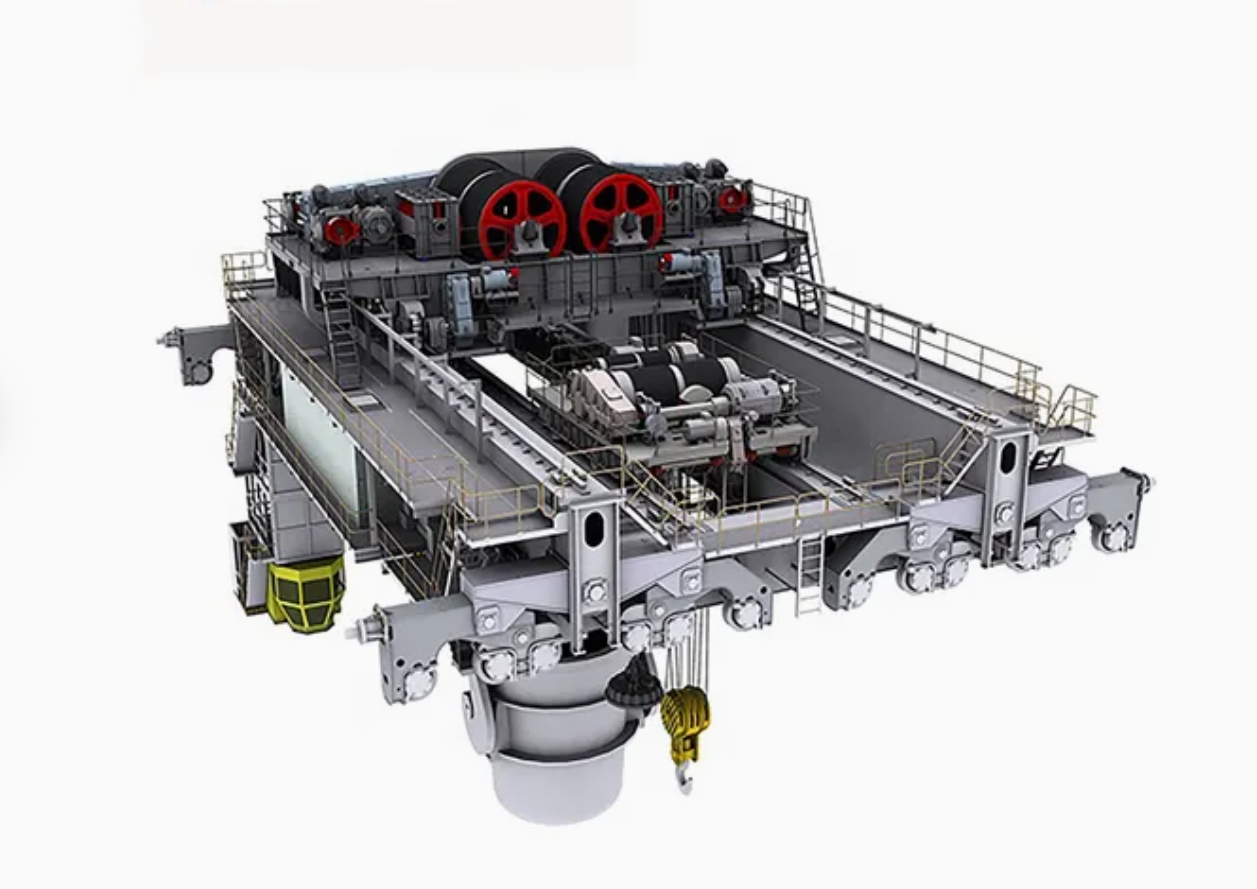

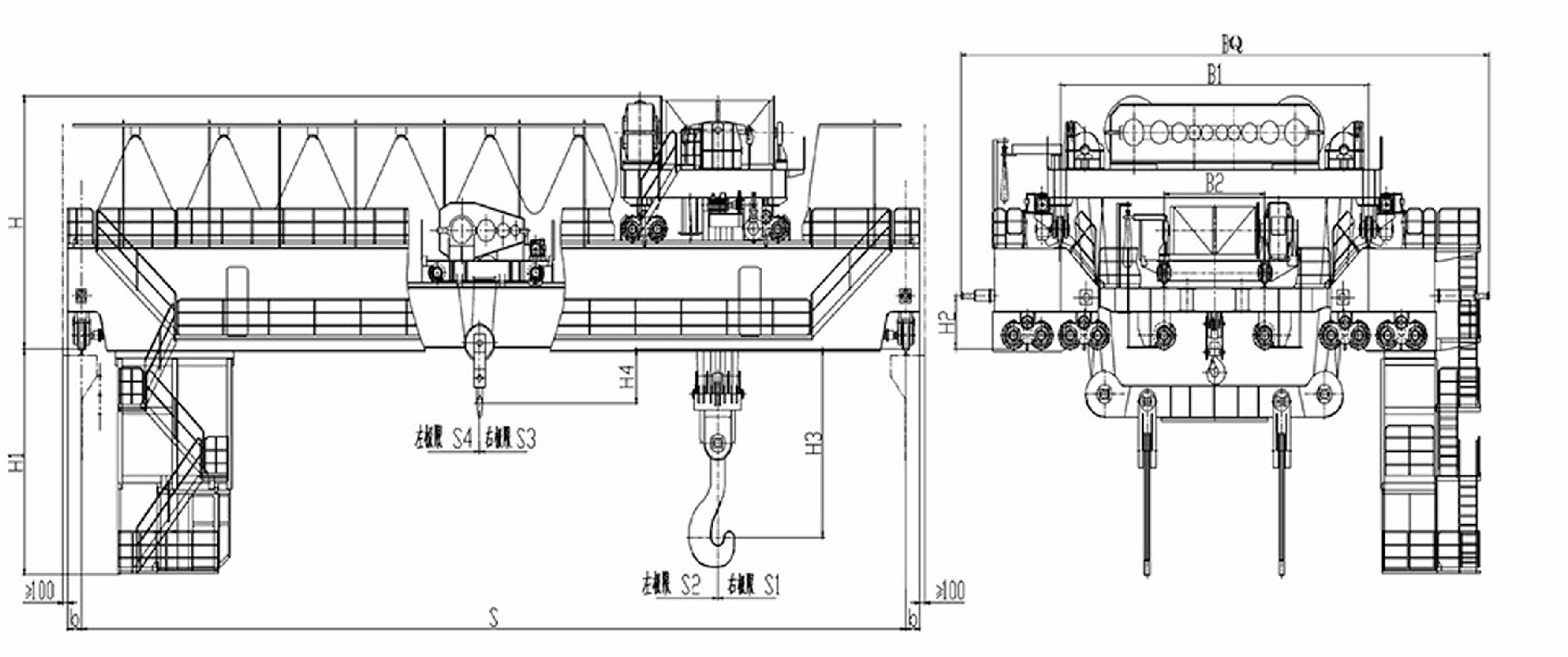

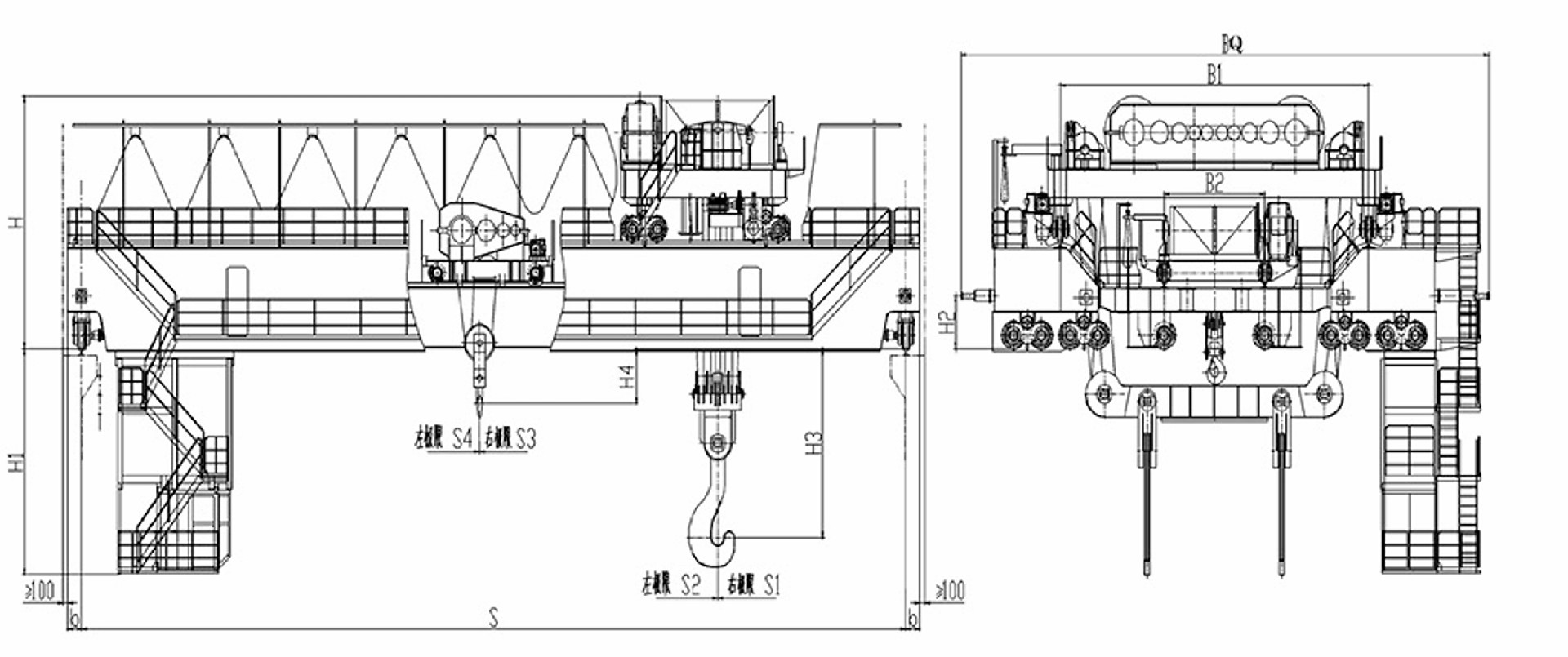

Henan Mine’s charging crane is a core component in steelmaking facilities, purpose-built for feeding electric arc furnaces (EAF) with scrap or molten metal. Designed for continuous operation under extreme heat, this overhead crane is also capable of delivering hot metal to the ladle furnace (LF) or continuous casting machine (CCM). Engineered with a four-girder configuration, it provides exceptional stability, lifting accuracy, and long service life.

V mnohých závodoch slúži tento žeriav aj ako záloha pre žeriavy na manipuláciu s lopatkami, čím sa zabezpečuje kontinuita výroby v kritických scenároch.

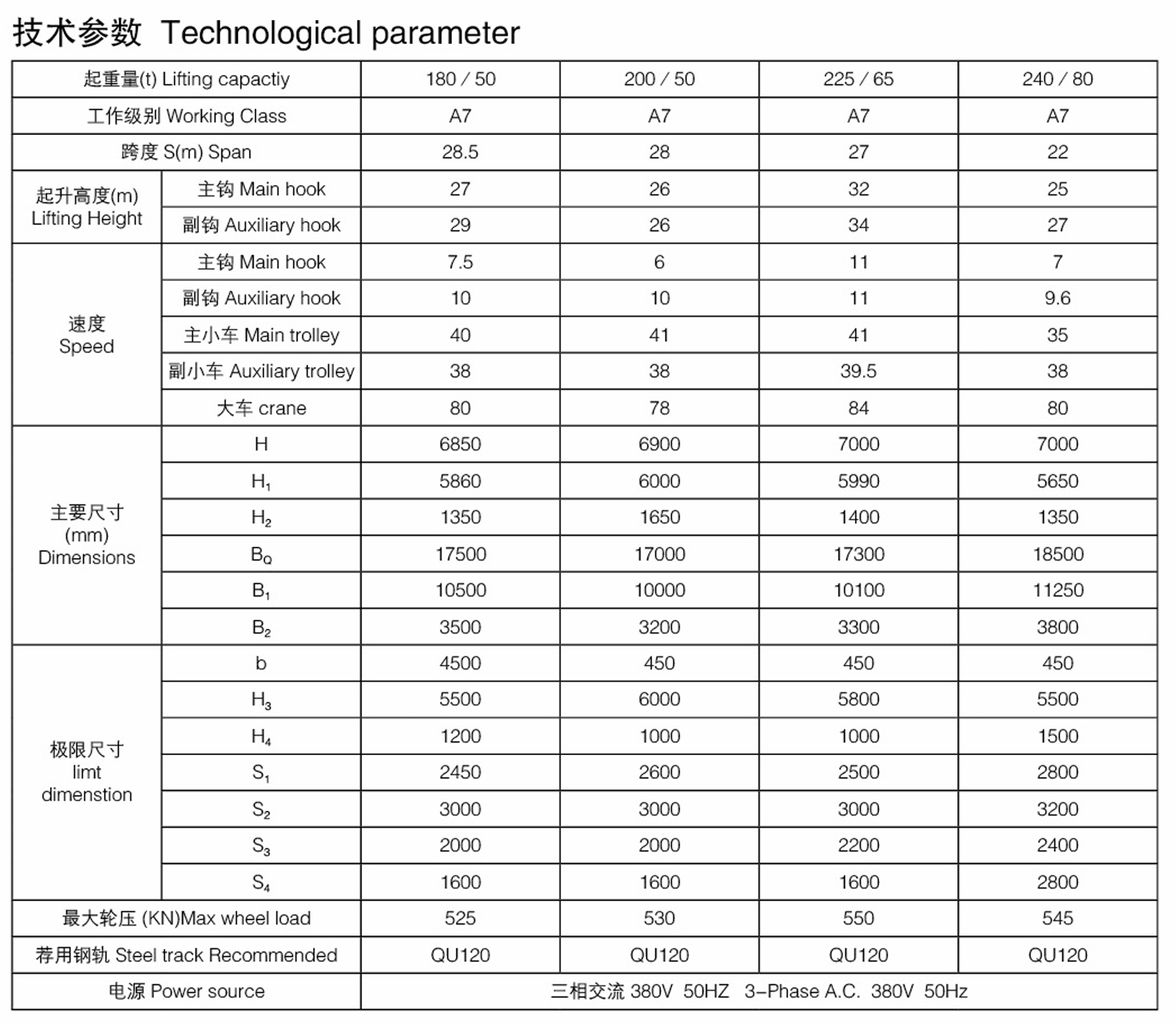

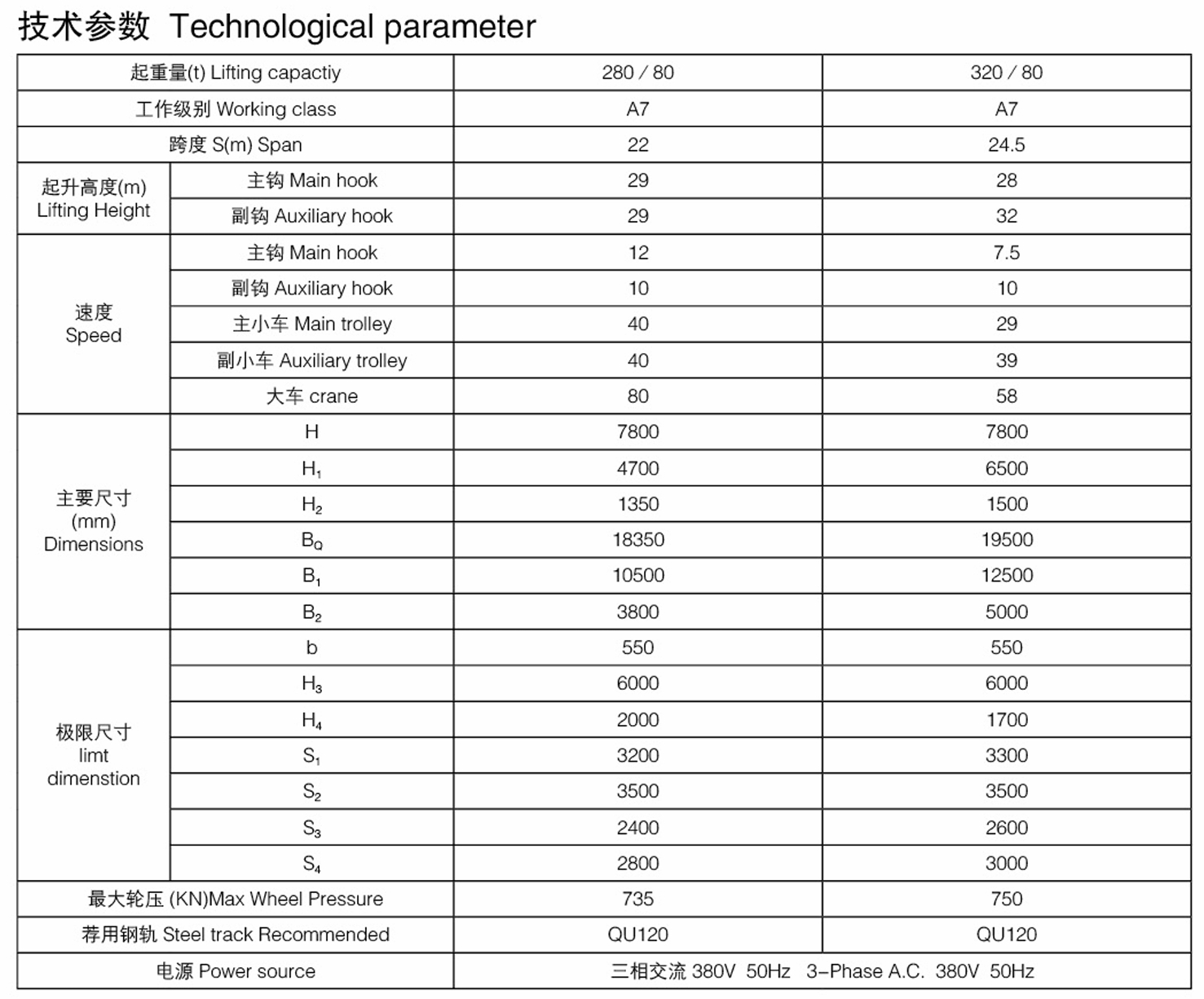

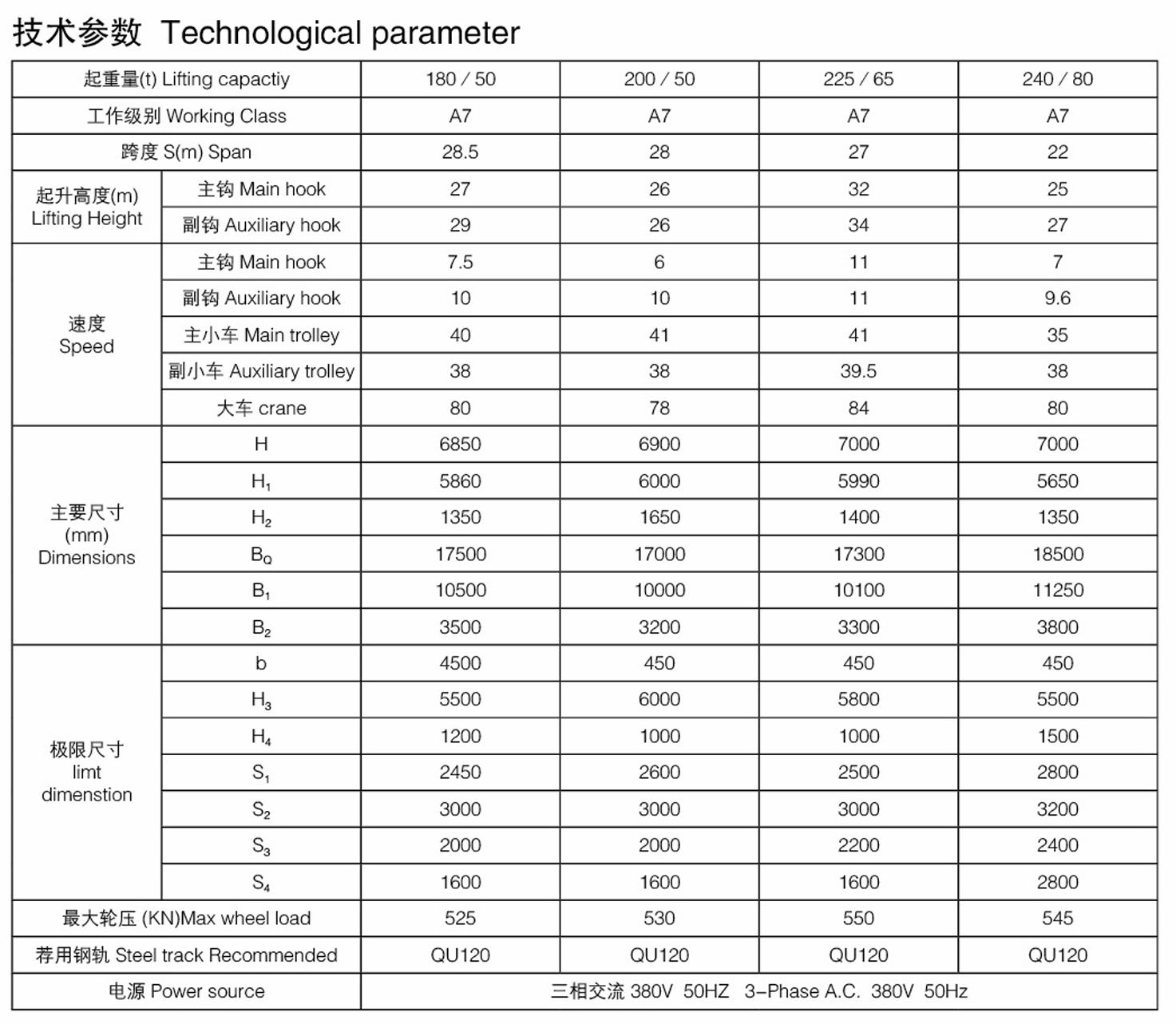

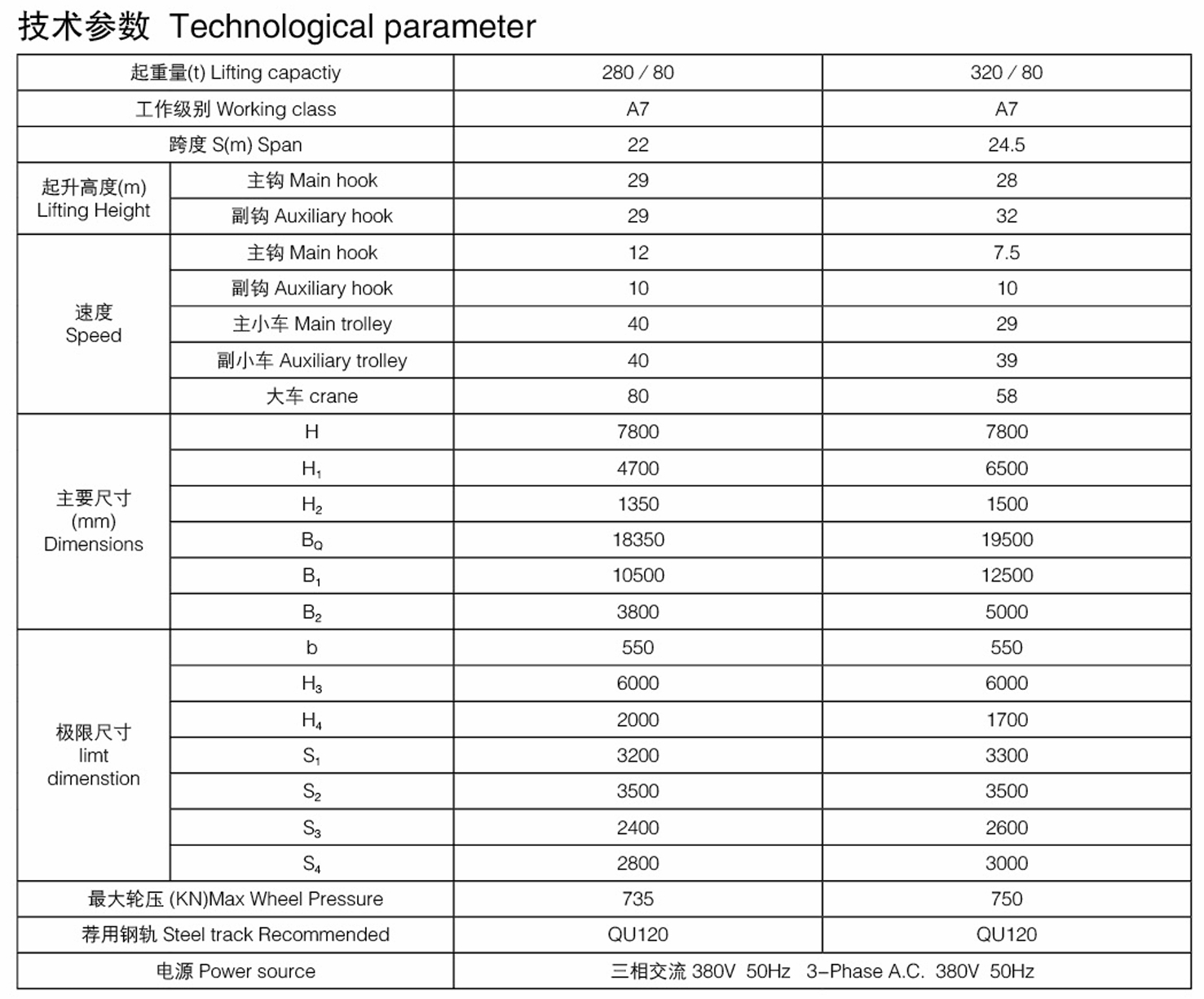

| Parametre | Hodnota / Rozsah |

| Typ žeriavu | Nadmorský nabíjací žeriav |

| Konštrukčný dizajn | Štyri nosníky s dvojitými vozíkmi |

| Zdvíhacia kapacita | Up to 500 tons (customized) |

| Zdvíhací mechanizmus | Dvojitý vozík so synchronizovaným pohonom |

| Aplikačné prostredie | Vysoké teplo, roztavený kov, 24/7 služba |

| Tepelná ochrana | Tepelná izolácia, plameňová ochrana |

| Napájanie | 3-fázový AC, prispôsobené napätie |

| riadiaci systém | Cabin + Optional Remote |

| redundancia | Zálohové brzdy, dvojité pohony, obmedzovače |

| Certifikácia | GB / ISO / CE v súlade |

Vyplňte nižšie uvedený formulár, aby ste získali okamžitý prístup k katalógu žeriavov a porozprávali sa s naším technickým tímom o odporúčaniach