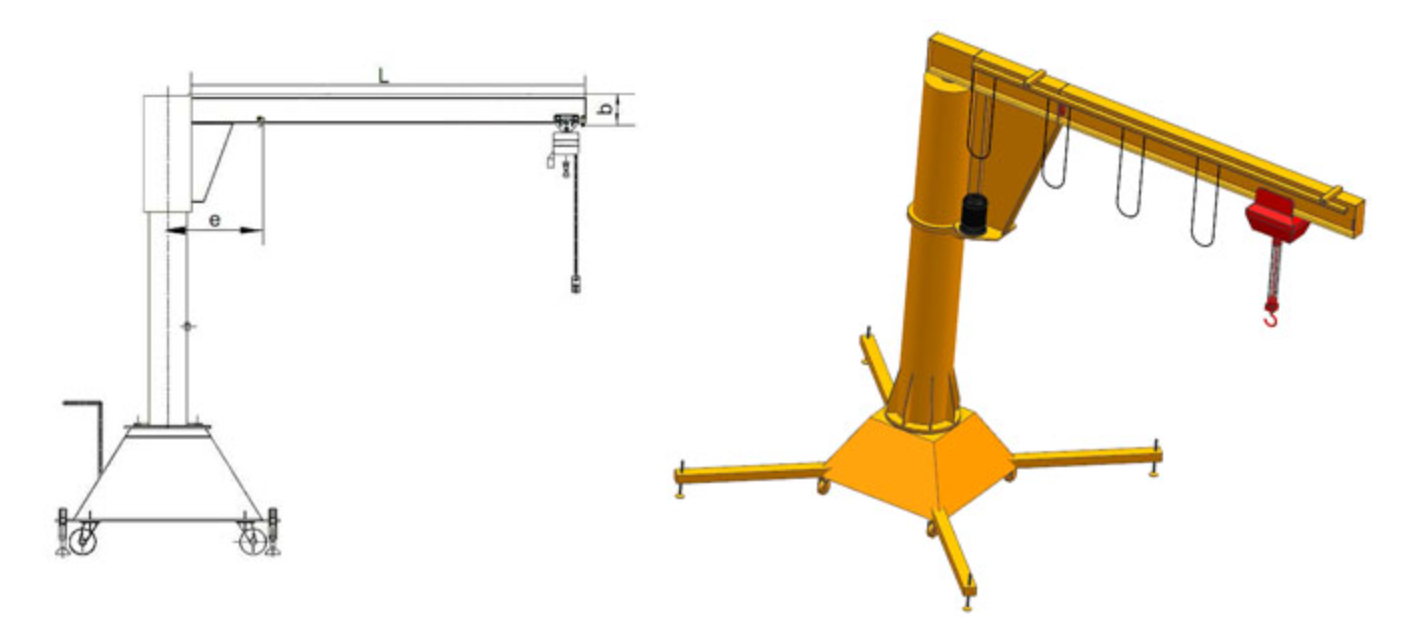

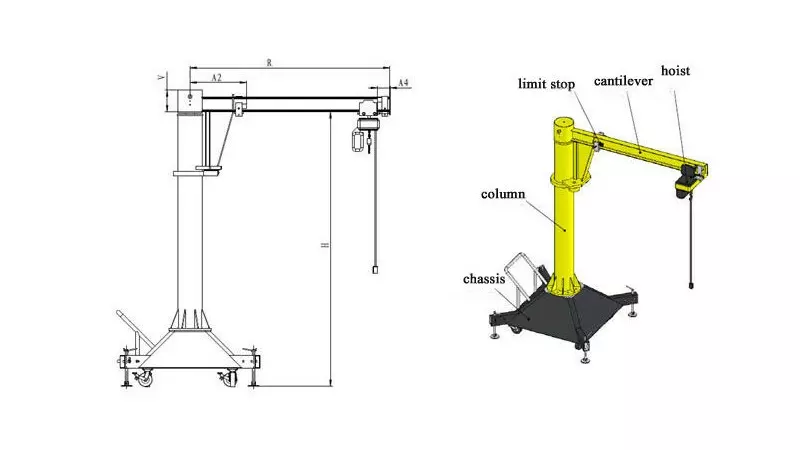

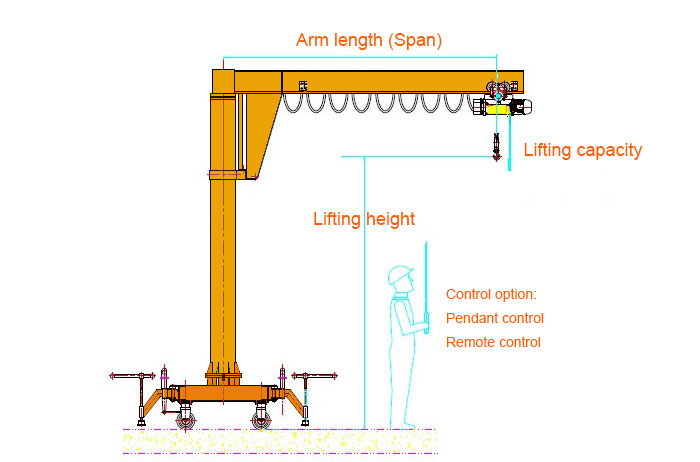

Prenosni nosilni žerjav

Prenosni nosilni žerjav

Izpolnite spodnji obrazec za takojšen dostop do kataloga žerjavov in se pogovorite z našo tehnično ekipo za popravke