Crane qolka nadiifka ah ee otomaatiga ah ee qaraxda

Crane qolka nadiifka ah ee otomaatiga ah ee qaraxda

Kor u qaadista saxda ah ee xilligii Semiconductor

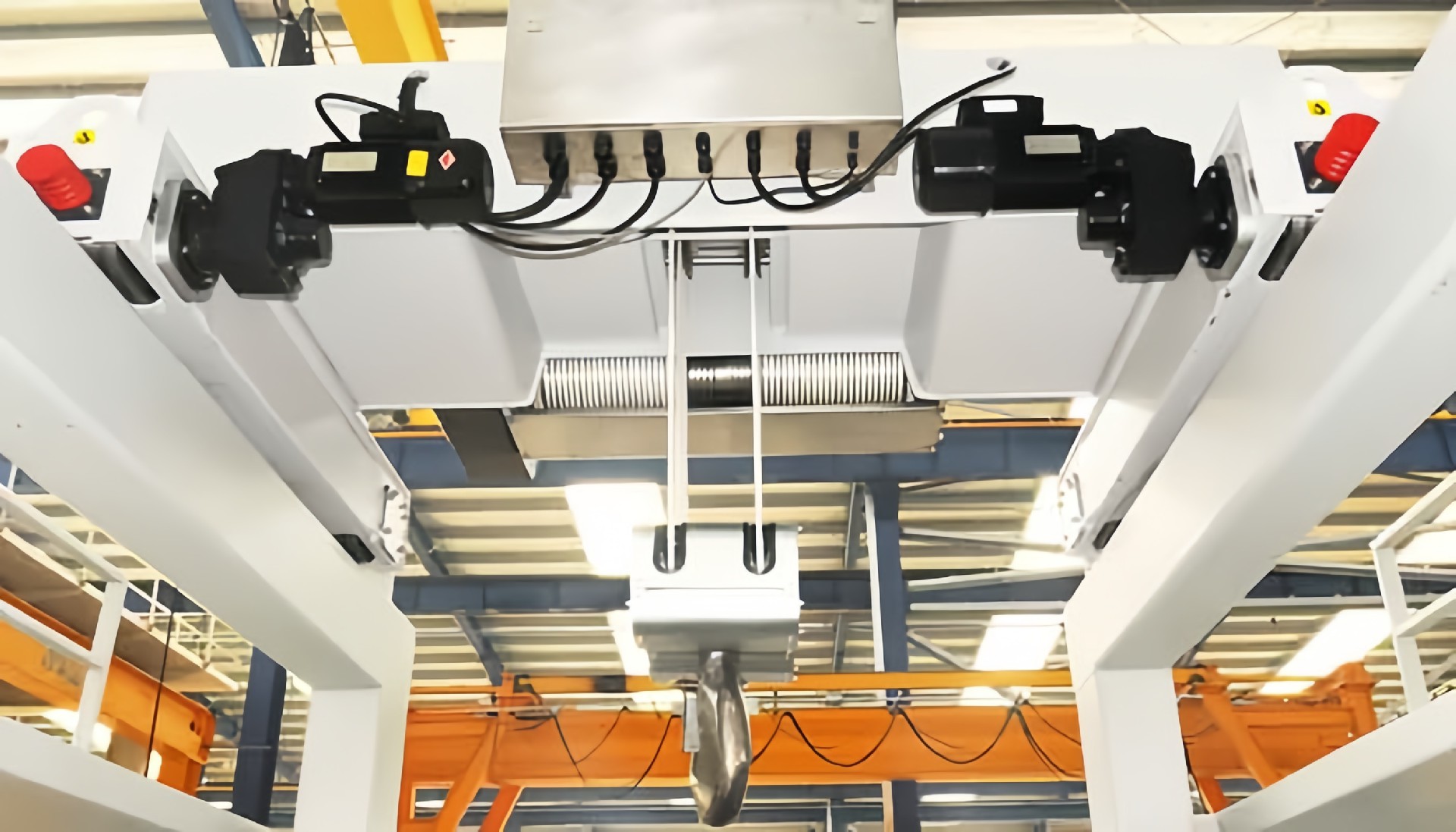

The Henan Mine Explosion-Proof Cleanroom Crane is a high-precision, fully automated lifting system built to meet the strictest cleanliness and safety standards in advanced semiconductor production and microelectronics assembly. Engineered for ISO Class 4 (Class 7 GB) cleanroom environments and certified to dIICT4 explosion-proof standards, this crane is designed to safely handle materials in flammable gas zones without compromising air purity or production efficiency.

Iyadoo la adeegsanayo otomaatiga kombiyuutarka dhexe, goobta laser, iyo qaybaha birta aan lahayn ee si buuxda loo xidhay, waxay bixisaa kor u qaadista xawaaraha sare, wasakheynta la'aan; iyadoo lagu kalsoonaan karo oo aan la isbarbar dhigin.

| Qalabka | Qeybta |

| Qolalka nadiifka ah | ISO Class 4 (GB Class 7) |

| Qiimeynta qaraxda | ee dIICT4 |

| Nidaamka Xakamaynta | Nidaamka kombiyuutarka ee otomaatiga ah ee dhexe |

| Nidaamka goobta | Laser barcode positioning (trolley & bridge) |

| Habka hawlgalka | Manual / Automatic (switchable & interlocked) |

| Nooca Motor | Mootor aan fiilooyin lahayn, oo qaraxda ka adkeysta, oo ilaalinta sare leh |

| Qalabka | Birta aan lahayn, ka hortagga daaweynta, ka hortagga daaweynta ee la xidhay |

| Qalabka & amp; Qalabka | Qalabka isku shaqeeya, ee la xiray; joogtada laba-xidhka ah |

| Badbaadada degdegga ah | E-joogitaanka fog, qabashada khaladka korontada |

Qalabka Xaaladaha xanuunka macaamiisha Xalli

| Xarunta xanuunka | Xalka macdanta Henan |

| Khatarta wasakheynta qolalka nadiifka ah | ✅& xiriir: Naqshadeynta si buuxda loo xidhay, qaybaha waafaqsan ISO Class 4 |

| Joogitaanka gaaska guba/qaraxa | ✅& xiriir: Qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka qalabka |

| Maareynta gacanta ee hoos u dhaca geedi socodka semiconductor | ✅& xiriir: Automation buuxda oo leh xakamaynta dhexe iyo goobta saxda ah |

| Waqtiga joogitaanka sababtoo ah dayactirka iyo guuldareynta | ✅& xiriir: Qalabka aan dayactir lahayn, sanduuqyada gearka ee la xiray, nidaamka joogitaanka qaladka |

| Meelaha culeyska ee aan joogto ahayn ee waxyeello ku yeelaya qaybaha jilicsan | ✅& xiriir: Gawaarida iyo buurtada lagu hoggaamiyo laser-ka oo leh saxnaanta heerka mm |

Buuxi foomka hoose si aad si degdeg ah u hesho buugga cranes-ka oo la hadlo kooxdeena farsamada si aad u hesho talooyin