Insulated Kulisha Overhead Crane kwa ajili ya Electrolytic Aluminium

Insulated Kulisha Overhead Crane kwa ajili ya Electrolytic Aluminium

Iliyoundwa na Henan Mine Salama, Sahihi, na Ilijengwa kwa Mazingira Magumu

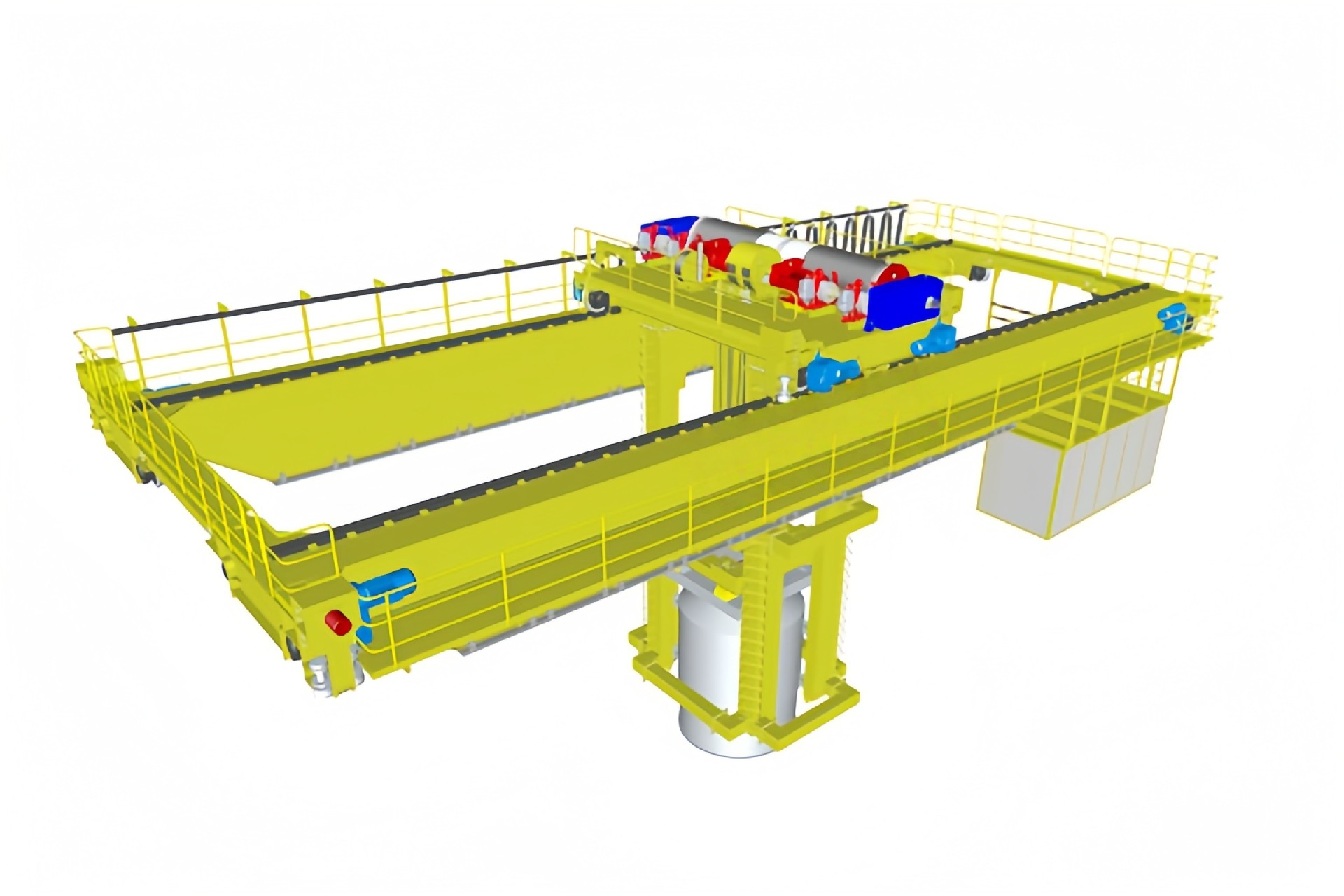

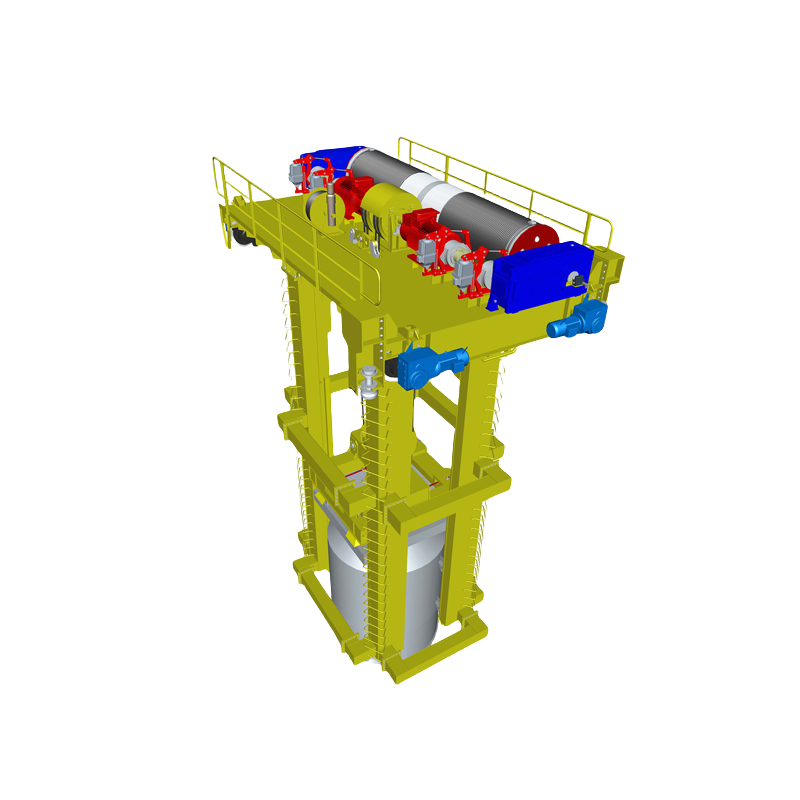

Henan Mine Insulated Kulisha Overhead Crane & nbsp; ni mfumo wa juu wa kuinua juu, hasa iliyoundwa kwa ajili ya sekta ya alumini ya umeme, ambapo hali kali za uendeshaji - kama vile chumvi iliyovunjika ya joto la juu, sasa nzito, mashamba ya sumaku yenye nguvu, na anga za kutu - zinahitaji ufumbuzi maalum sana.

Crane hii inachanganya teknolojia ya insulation ya voltage ya juu, kubuni ya kupambana na sumaku, na trolley ya kulisha ya kujitolea; kutekeleza kazi muhimu za uzalishaji ikiwa ni pamoja na kulisha alumini fluoride, kuchukua alumini iliyovunjika, kushughulikia muundo wa seli, na zaidi. Inaaminika na wazalishaji wa juu wa alumini, ina jukumu kuu katika kuhakikisha shughuli za kuendelea, salama, na moja kwa moja ndani ya mimea ya kulevya.

| Uwezo wa Kuinua | Custom-configured (typically 10–74 tons) |

| Configuration ya Crane | Tatu-boriti, tatu-trolley mpangilio |

| Trolleys maalum | Tool Trolley (hook-type lifting);Aluminum Extraction Trolley (with insulated, anti-sway hook & weighing system);Feeding Trolley (with hopper, discharge system & electronic measuring unit) |

| Utaratibu wa Kusafiri | 8-gurudumu, mbili-gari na shaft-imewekwa 3-katika-1 reducers |

| Njia za Udhibiti | Cabin control + remote diagnostics |

| Ushirikiano wa Mazingira | Anti-corrosion materials + sealed electronics |

| Waendeshaji Cabin | Vifaa na viwanda HVAC kwa hali ya joto kali |

| Viwango vya Usalama | GB, ISO, CE-kufuata |

Jaza fomu hapa chini ili kupata upatikanaji wa haraka kwa cranes orodha na kuzungumza na timu yetu ya kiufundi kwa ajili ya recommendations