Suw Kurtarma Crany

Suw Kurtarma Crany

Gerçeklik. Resistent. Helikopter Kurtarma Ewezamy - Henan Min tarapyndan

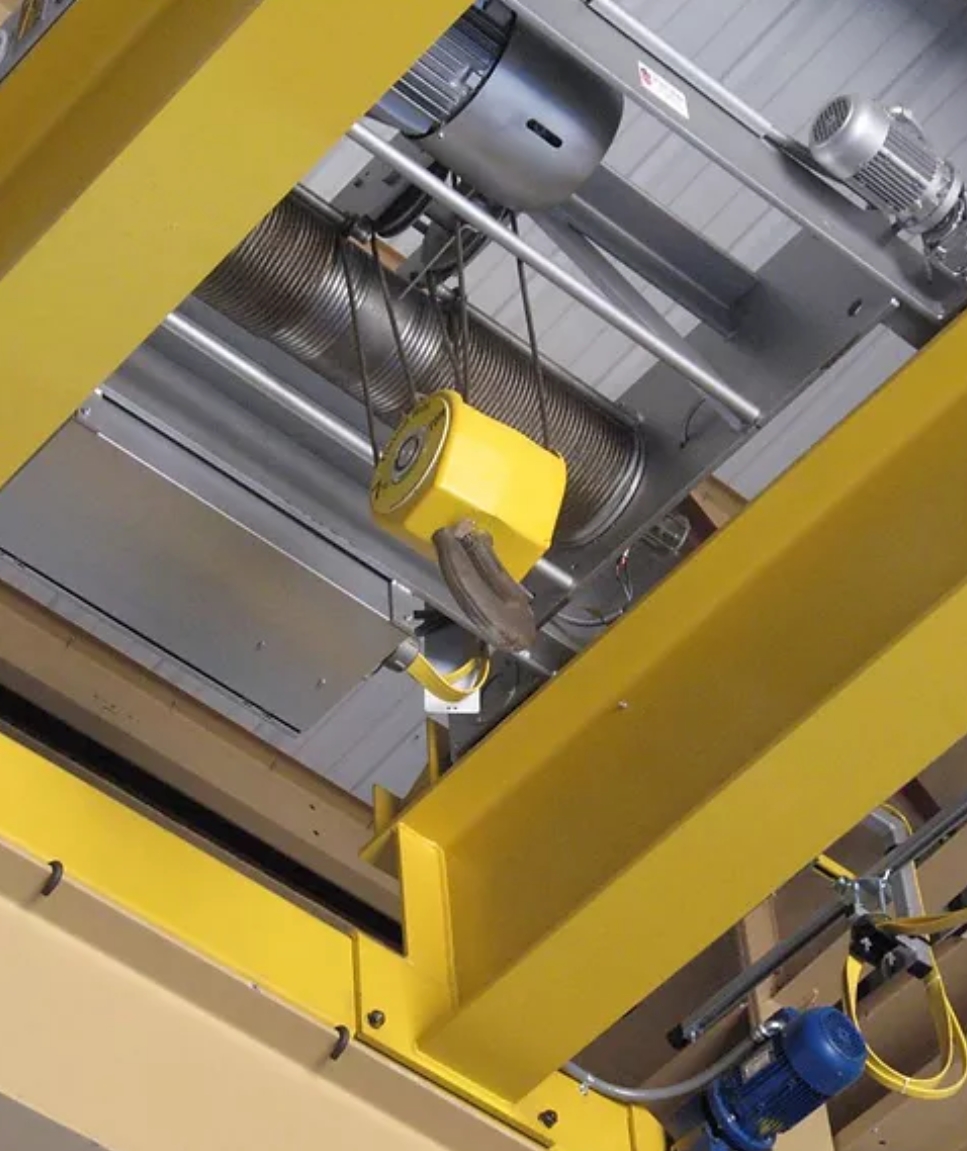

Henan Min tarapyndan janlaşdyran we üretilen suw kurtarmagynyň kranyny, helikopter kurtarmagynyň merkezleri üçin pioneerli okuw sanatynyň maksady. Günbatar teminatçylaryň uzak duran teknik monopolyny döwürmekde bu cran deniz kurtaryş şartlarynyň doly täsirli, realistik simülasy ýagdaýynda ýokary howlar, rotor ýuwygy, turbulent suw we tupança ýaly şertleri bar.

Iň isleýän okuwçy ortamlaryň käbirlerinde barlanýar, hakyky dünýä ajaýyp wagtlar üçin kurtarma profesionallaryny taýýarlamak üçin hasaplanýar—gelişmiş kontrol, güvenlik we simulasyon özellikleri bilen. AB we Halkara güvenlik standartlary bilen guruldy, diňe dogrudylyk däl, ýokary riskli eğitim operasiýasynda ýok-ýok ynamlylyk saýlamaýar.

| Görniş Opşenler: | Anil duran funksiýasy bilen 360 sany gaýd etmek mümkin |

| Etrap Görkezilişi | Simüle edilen kyn deňzinler, ýagşy baglaýyşlar, güýçli howlar we töwletler altynda işleýär |

| Sykmak | ISO, GB we AB enjamlaryň howpsuzlyk standartlary bilen tanyşdyrylmagy mümkin edildi. |

| Emnyýet sistemi | Çoklu dereje ýalňyşlyk diagnostiki, reýl-wagtyň alamatlary we gatlak gorkeýşenler protokollary |

| Kontrol Sistemi | Precision point-positioning + programmable rescue trajectory simulation |

| Crane Hili | Dinamik ýuwçylyk sistemleri bilen görkezilýän aýratyn tekniýerler |

| Ýer | Koroziýa garşy we howa-garşyrlanylan elektronika |

| Güç Maglumaty Mümkin Et | Customized for stable operation in training base environments (optional UPS integration) |

Häzirki resim katalogyna gollanmak üçin aşakda formy dolduruň we täzeliklerimiz üçin tekniki toparymyza gürleşiň.