- What is a Double Girder Gantry Crane? The Complete Guide.

-

ian Nao:2025-09-01 14:25:52jis pok:

What is a Double Girder Gantry Crane? The Complete Guide.

For enterprises in metallurgy, construction, logistics, ports, and other sectors, efficiency and safety are paramount. Among various crane types, the double girder gantry crane stands out for its exceptional stability, high load capacity, and versatility. Compiled by Henan Mine Crane's sales experts with 30 years of industry experience, this article provides a detailed explanation of the double-girder gantry crane's definition, structure, and core advantages. It also offers solutions addressing common buyer concerns such as model selection and cost control. Operating on ground-laid rails, it enables horizontal movement within large-scale work areas.

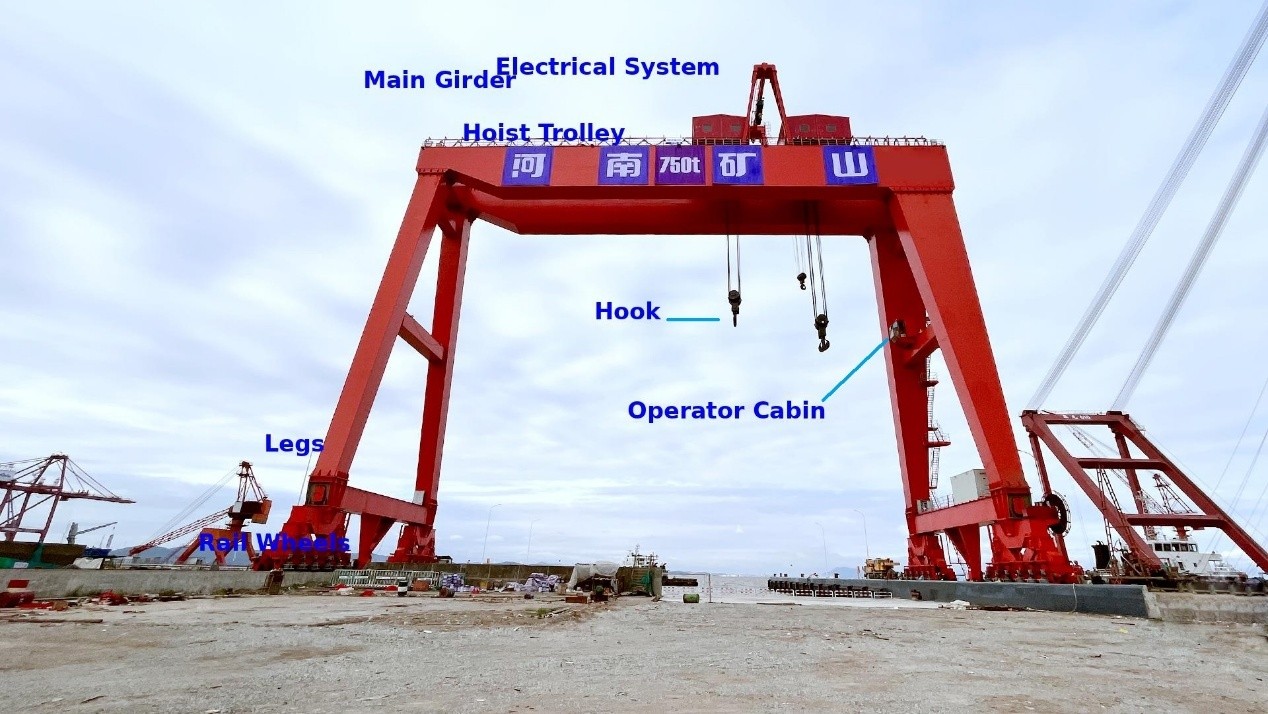

Its core components include:

Unlike bridge cranes, double-girder gantry cranes operate independently, making them particularly suitable for construction sites, open-air stockyards, ports, and similar environments.

Control System: Standard PLC or manual control; high-end models support remote operation and automated running

Safety Devices: Essential safety components including overload protection, limit switches, emergency brakes, and anti-sway devices

Double Main Girders: Typically constructed from high-strength steel, offering high load capacity with minimal deformation

Support Legs: Provide structural stability, equipped with adjustable bases to accommodate uneven ground

Trolley and Hoisting Mechanism: The trolley travels along the main girders, while the hoisting mechanism handles vertical lifting

II. Core Advantages of Double-Girder Gantry Cranes

| Feature | Double Girder Gantry Crane | Single Girder Gantry Crane |

| Lifting Capacity | 5–550 tons (supports ultra-heavy loads) | 1–20 tons (limited to light/medium loads) |

| Span Range | 10.5–31.5 meters (covers larger workspaces) | 5–20 meters (narrower coverage) |

| Stability & Durability | Double girders distribute weight evenly; 15–20 year lifespan | Single girder prone to deformation; 8–12 year lifespan |

| Customization | Supports add-ons (grabs, electromagnetic container spreaders) | Limited accessory compatibility |

| High-Frequency Use | Ideal for ≥100 cycles/day (robust drive system) | Suitable for ≤50 cycles/day (light-duty only) |

Three Core Values for Enterprises:

High Cost-Effectiveness: Durable components reduce maintenance costs, with 10-year maintenance expenses 20%-30% lower than single-girder models

Heavy-Load Versatility: Capable of handling containers, steel coils, large machinery, and other heavy loads—essential for steel mills, ports, and similar applications

Expandable Performance: Adaptable to specialized environments, facilitates upgrades for automation or explosion-proof capabilities.

III. Common Issues and Solutions

We provide end-to-end solutions for double-girder gantry cranes, from model selection to cost management.

Common Issue 1: How to Select Appropriate Equipment Parameters?

Uncertainty regarding required crane capacity and lifting height.

Solution:

Calculate lifting capacity: Add a 10%-20% safety margin to the heaviest load weight.

FAQ 2: Which industries are best suited for double-girder gantry cranes?

Double-girder gantry cranes excel in high-load and long-span applications, with core industries including:

Container Terminals & Ports: Handling 20-40 ft containers with customized lifting attachments

Steel mills, metallurgy: Transporting molten steel ladles with optional high-temperature resistant components

Infrastructure projects, construction: Lifting heavy components like precast beams and bridge pier modules

Logistics warehouses: Stacking steel or machinery, saving 70% storage space.

Case Study: After installing our 80-ton double-girder gantry crane, a Vietnamese port increased container handling efficiency by 45% compared to previous operations.

FAQ 3: What factors influence procurement costs? Concerns about budget overruns or hidden fees.

Solution: Clarify cost structure and optimize selection:

Core Parameters: Lifting capacity accounts for approx. 30% of cost; span approx. 20%—key influencing factors.

Configuration Levels:

Basic model, manual control: Starting price $5,000–10,000 USD; Mid-to-high-end models with PLC + automation: $10,000–$30,000 price range;

Value-added services: Avoid hidden costs like installation and transportation by selecting suppliers with transparent quotations.

Henan Mining Commitment: Equipment + installation + training provided with detailed itemized quotes—no hidden fees.

Frequently Asked Question 4: How to reduce long-term maintenance costs?

Solutions:

Select premium components: Henan Mine Crane exclusively uses Schneider Electric components and Siemens motors, reducing failure rates by 80%.

IV. Henan Mine Crane's One-Stop Solution for Double-Girder Gantry Cranes

Turnkey Service: Includes on-site installation, operator training, and 24/7 global after-sales support via 20 overseas service centers

Cost Advantage: Factory-direct pricing, 15%-20% lower than intermediary rates

If my operation requires “lifting capacity ≥5 tons, covering large spaces, or sustained high-frequency operation,” can it meet my needs?

— The answer is yes. Double-girder gantry cranes not only boost efficiency and reduce safety risks but also deliver long-term cost optimization.

For customized solutions:

WhatsApp: 18836207779

Website: www.cranehenanmine.com

Email: Lsabella@cranehenanmine.com