Guhindura izina

Guhindura izina

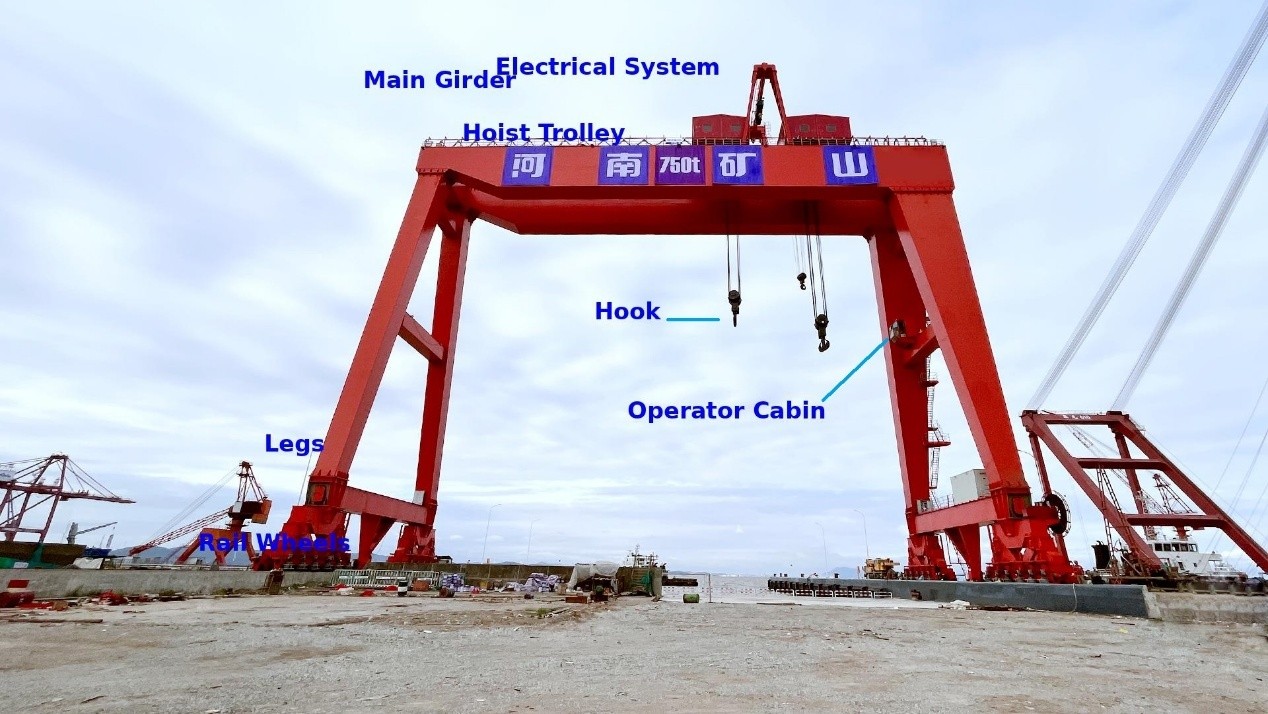

Ubushobozi bwo gukoreshwa. kugirango Kuri

KURI 20 IMYAKA in i, Kuri:, hasi,, na nibyo Kinini -.

MAHARAKUBIRI ni ya: Imbaraga, na. 20 Bya in Cyangwa 7 ku a iyi ni Kuri

i ku, Cyangwa. buri ni Kuri - OYA Igerageza Ibisabwa.

| Agaciro | |

| Umumaro | 5 - 1000 |

| Span | 18 - Metero |

| Ubuhagarike | 6 / 9 / 12 meters Cyangwa Kunozwa |

| A3 – A8 (continuous, heavy-duty) | |

| -, 50-, | |

| Ibisabwa | -25℃ to +45℃, humidity ≤85% |

| Amagenzura | /// |

in i Ifishi% S: munsi Kuri Kubona By' ako kanya Kuri i Agatabo na Kuri ya: