Sistema Cartae Aluminium Coil Electrica Transferentia

Sistema Cartae Aluminium Coil Electrica Transferentia

Precision Transport for Coil Handling – Engineered by Henan Mine

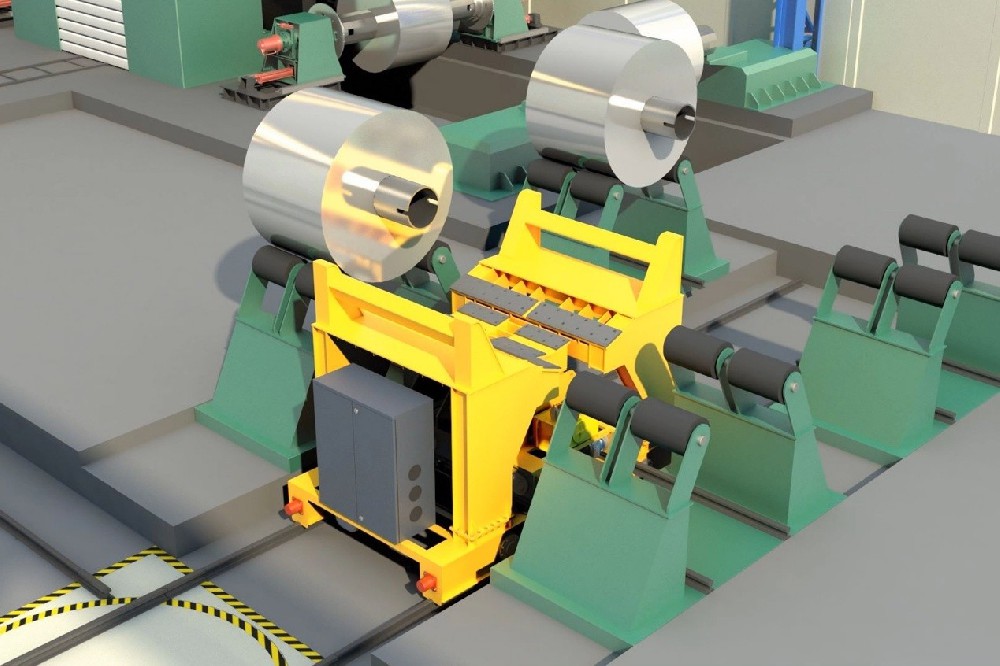

The Aluminum Coil Electric Transfer Cart System de Henan Mine nbsp; is a fully integrated coil transport solution designed to meet the specific needs of aluminum processing plants and rolling mills. Built to streamline coil movement, reduce handling risks, and improve production flow, this system plays a key role in modernizing aluminum coil logistics.

Featuring a parent-child cart configuration, this system ensures safe, accurate, and automated transport of finished aluminum coils between production lines, buffer storage areas, and send zones. Whether installed in a newly automated facility or retrofitted into an existing workshop, it delivers operational continuity and material protection at every stage.

| Parent Cart | Mounted on rails, with saddle + conveyor system;Child Cart |

| Capacitate elevationis | 5 – 60 tons (customizable per coil weight and dimensions) |

| Velocitate viae | Up to 60 m/min (adjustable via frequency inverter) |

| Positioning precision | ±2 mm with sensor-based alignment |

| Genia | Embedded steel rail or overhead-guided line |

| drive-with-type | Electric motor + gear reducer with soft-start control |

| Power Supply | Cable drum / low-voltage rail / battery (site-dependent) |

| Systemae securitate | Obstacle detection, overload protection, emergency stop |

| Compliance | ISO, GB, CE-certified components |

Fill in the form below to get instant access to the cranes catalog and speak to our technical team for recoomendations