- What types of gantry cranes are there, and what are the characteristics of each type?

-

ran Zi:2025-07-23 10:43:00ed b:

Gantry cranes are a type of crane where the bridge is supported on ground rails or foundations via legs on both sides, widely used in ports, yards, workshops, and other scenarios. They can be divided into various types based on structural form, application, and operation mode, each with unique characteristics, as follows:

1. Classified by Structural Form

(1) Full Gantry Crane

Structural features: The two ends of the bridge are supported on ground rails through rigid legs on both sides. The legs are door-shaped, forming a fully enclosed "gantry" structure.

Applicable scenarios: Suitable for open yards, ports, and other areas requiring large-scale operations, covering the entire space between the two rails.

Advantages: Wide operating range, strong stability, and ability to carry large weights (from tens of tons to thousands of tons). 2) Semi-Gantry CraneStructural features: One end of the bridge is supported on rails via rigid legs, while the other end is directly supported on the ground or a concrete foundation of a factory building (no leg or only a flexible leg).

2) Semi-Gantry CraneStructural features: One end of the bridge is supported on rails via rigid legs, while the other end is directly supported on the ground or a concrete foundation of a factory building (no leg or only a flexible leg).

Applicable scenarios: Often used when there are obstacles (such as buildings, other equipment) on one side of the site, or when it is necessary to save the cost of rails on one side (e.g., workshop edges, warehouse).

Advantages: High flexibility, adaptable to irregular sites, and balances a certain operating range with cost control. 2. Classified by Application

(1) Container Gantry Crane

Features: Designed specifically for container loading and unloading, with retractable or luffing spreaders that can quickly grab and transport standard containers (20-foot, 40-foot, etc.).

Subtypes:

Rubber-Tired Gantry Crane (RTG): Uses tires for movement, suitable for flexible scheduling in yards, no need for rail laying, but has high requirements for ground bearing capacity.

Rail-Mounted Gantry Crane (RMG): Runs along rails, with a fixed operating range and stronger stability, suitable for efficient operations in large ports or yards.

Advantages: High degree of automation (capable of unmanned operation), fast loading and unloading efficiency, and precise container stacking.

2. Classified by Application

(1) Container Gantry Crane

Features: Designed specifically for container loading and unloading, with retractable or luffing spreaders that can quickly grab and transport standard containers (20-foot, 40-foot, etc.).

Subtypes:

Rubber-Tired Gantry Crane (RTG): Uses tires for movement, suitable for flexible scheduling in yards, no need for rail laying, but has high requirements for ground bearing capacity.

Rail-Mounted Gantry Crane (RMG): Runs along rails, with a fixed operating range and stronger stability, suitable for efficient operations in large ports or yards.

Advantages: High degree of automation (capable of unmanned operation), fast loading and unloading efficiency, and precise container stacking. (2) Shipbuilding Gantry Crane

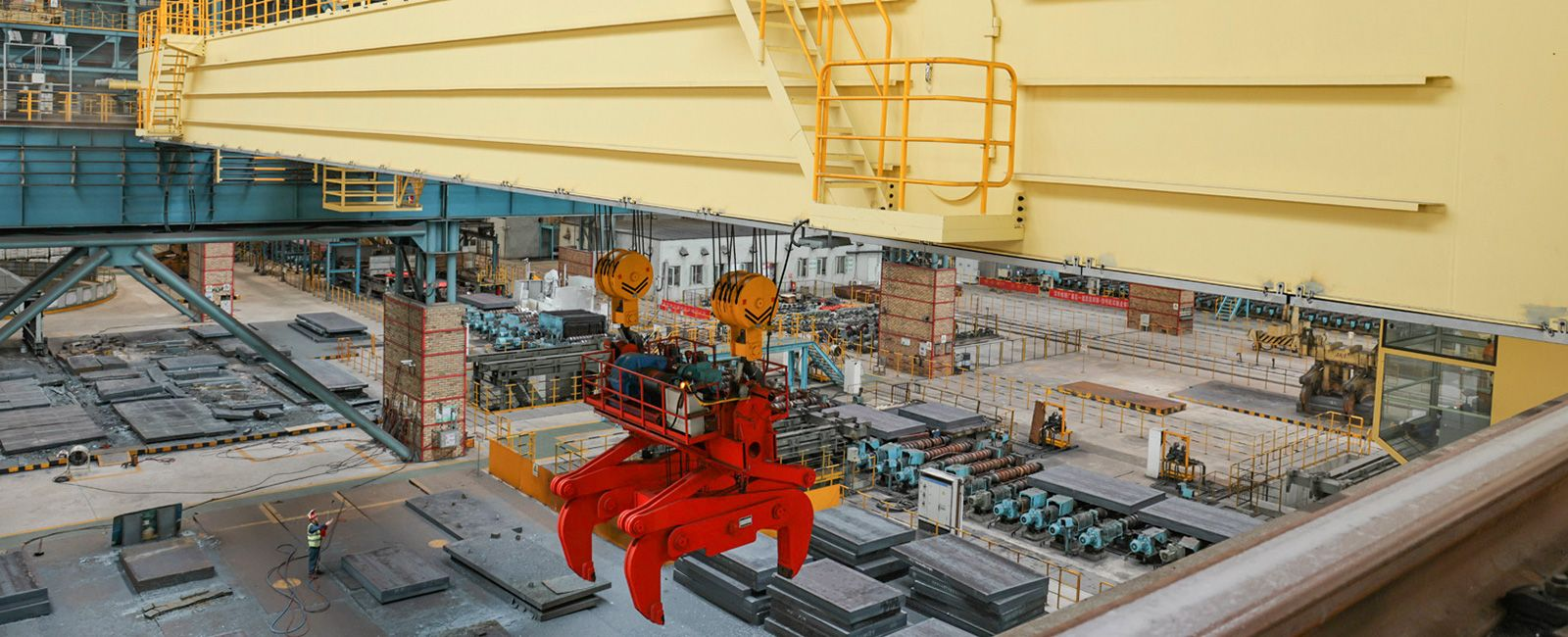

Features: Large in size and with extremely high lifting capacity (up to thousands of tons), mainly used for hoisting heavy components such as hull sections and engines during ship construction.

Structure: Usually a double-main-beam full gantry structure with a large span (up to over 100 meters), featuring precise control functions in multiple directions such as trolley, crab, and hoisting.

Advantages: Extremely strong load-bearing capacity, stable operation, and can meet the high-precision requirements for hoisting heavy components in the shipbuilding industry.

(2) Shipbuilding Gantry Crane

Features: Large in size and with extremely high lifting capacity (up to thousands of tons), mainly used for hoisting heavy components such as hull sections and engines during ship construction.

Structure: Usually a double-main-beam full gantry structure with a large span (up to over 100 meters), featuring precise control functions in multiple directions such as trolley, crab, and hoisting.

Advantages: Extremely strong load-bearing capacity, stable operation, and can meet the high-precision requirements for hoisting heavy components in the shipbuilding industry. (3) General-Purpose Gantry Crane

Features: Versatile, capable of handling various materials such as steel, equipment, and bulk goods, with diverse spreader forms (e.g., hooks, grabs, electromagnetic).

Applicable scenarios: Factory workshops, warehouses, open yards, etc., especially suitable for frequent loading, unloading, and handling of small and medium-sized goods.

Advantages: Strong versatility, can replace spreaders according to needs, and flexible in operation.

(3) General-Purpose Gantry Crane

Features: Versatile, capable of handling various materials such as steel, equipment, and bulk goods, with diverse spreader forms (e.g., hooks, grabs, electromagnetic).

Applicable scenarios: Factory workshops, warehouses, open yards, etc., especially suitable for frequent loading, unloading, and handling of small and medium-sized goods.

Advantages: Strong versatility, can replace spreaders according to needs, and flexible in operation. (4) Hydropower Station Gantry Crane

Features: Designed specifically for hydropower stations, used for hoisting large equipment such as turbines and generators, as well as opening and closing gates.

Special requirements; Need to adapt to the humid and dusty environment of hydropower stations, some also need to have explosion-proof and anti-corrosion functions, with high requirements for operation accuracy.

Advantages: High reliability, can operate stably for a long time under complex working conditions, ensuring the normal operation of hydropower stations.

3. Classified by Operation Mode

(1) Rail-Mounted Gantry Crane

Features: Runs along rails laid on the ground, with a fixed direction of trolley movement, and the operating range is limited by the length of the rails.

Advantages: Stable operation, strong load-bearing capacity, suitable for large-volume, high-intensity operations in fixed areas (e.g., port yards).

(4) Hydropower Station Gantry Crane

Features: Designed specifically for hydropower stations, used for hoisting large equipment such as turbines and generators, as well as opening and closing gates.

Special requirements; Need to adapt to the humid and dusty environment of hydropower stations, some also need to have explosion-proof and anti-corrosion functions, with high requirements for operation accuracy.

Advantages: High reliability, can operate stably for a long time under complex working conditions, ensuring the normal operation of hydropower stations.

3. Classified by Operation Mode

(1) Rail-Mounted Gantry Crane

Features: Runs along rails laid on the ground, with a fixed direction of trolley movement, and the operating range is limited by the length of the rails.

Advantages: Stable operation, strong load-bearing capacity, suitable for large-volume, high-intensity operations in fixed areas (e.g., port yards). (2) Rubber-Tired Gantry Crane

Features: Uses tires as running devices, can move freely on flat ground without rails, with extremely high flexibility.

Advantages: Strong site adaptability, can quickly adjust the operating position, suitable for small and medium-sized yards or scenarios requiring temporary scheduling, but the lifting capacity is relatively lower than that of rail-mounted ones.

(2) Rubber-Tired Gantry Crane

Features: Uses tires as running devices, can move freely on flat ground without rails, with extremely high flexibility.

Advantages: Strong site adaptability, can quickly adjust the operating position, suitable for small and medium-sized yards or scenarios requiring temporary scheduling, but the lifting capacity is relatively lower than that of rail-mounted ones. Summary

Different types of gantry cranes meet the specific needs of different industries (such as ports, shipbuilding, hydropower, manufacturing) through differentiated designs in structure, application, and operation mode. The selection should be comprehensively considered based on factors such as the operating environment, load requirements, and flexibility needs to ensure efficient and safe material handling.

Summary

Different types of gantry cranes meet the specific needs of different industries (such as ports, shipbuilding, hydropower, manufacturing) through differentiated designs in structure, application, and operation mode. The selection should be comprehensively considered based on factors such as the operating environment, load requirements, and flexibility needs to ensure efficient and safe material handling.