Sistem Keranjang Pemindahan Elektrik Gegulungan Aluminium

Sistem Keranjang Pemindahan Elektrik Gegulungan Aluminium

Pengangkutan ketepatan untuk pengendalian gegelung Dijurutera oleh Henan Mine

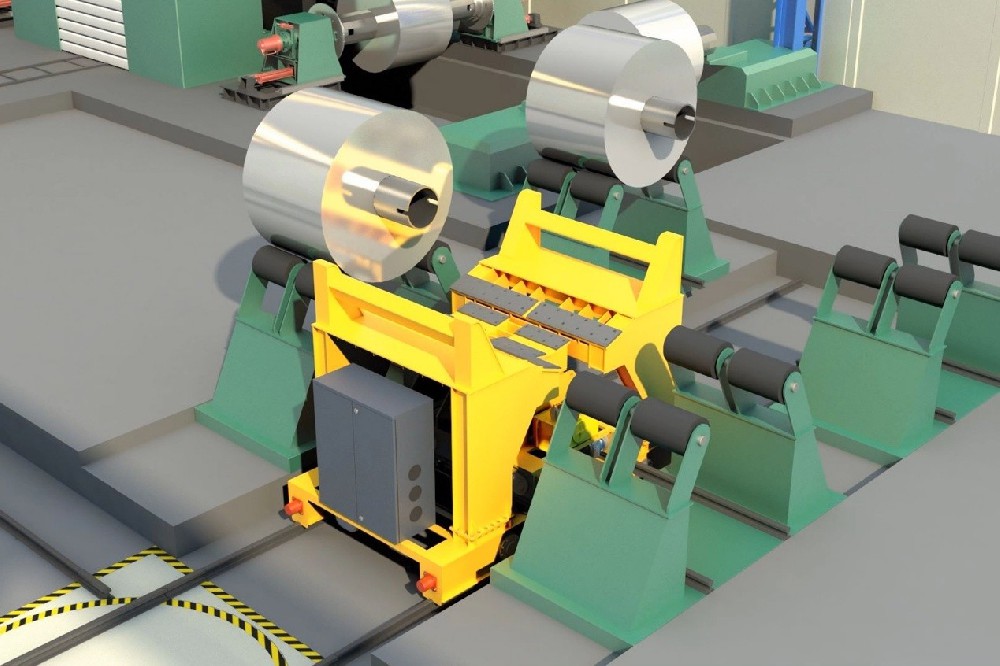

Sistem Kereta Pemindahan Elektrik Gegulungan Aluminium & nbsp; daripada Henan Mine adalah penyelesaian pengangkutan gegelung bersepadu sepenuhnya yang direka untuk memenuhi keperluan khusus kilang pemprosesan aluminium dan kilang gulung. Dibina untuk menyederhanakan pergerakan gegelung, mengurangkan risiko pengendalian, dan meningkatkan aliran pengeluaran, sistem ini memainkan peranan utama dalam memodenkan logistik gegelung aluminium.

Mempunyai konfigurasi kereta ibu bapa-anak, sistem ini memastikan pengangkutan yang selamat, tepat, dan automatik gegelung aluminium siap antara barisan pengeluaran, kawasan penyimpanan penyangga, dan zon penghantaran. Sama ada dipasang di kemudahan automatik yang baru atau dilengkapi ke bengkel sedia ada, ia memberikan kesinambungan operasi dan perlindungan bahan pada setiap peringkat.

| Konfigurasi Sistem: Keranjang Ibu bapa | Mounted on rails, with saddle + conveyor system;Child Cart |

| Kapasiti Angkat | 5 – 60 tons (customizable per coil weight and dimensions) |

| Kelajuan Perjalanan | Up to 60 m/min (adjustable via frequency inverter) |

| Ketepatan Kedudukan | ±2 mm dengan penyelarasan berasaskan sensor |

| Jenis trek | Kereta api keluli tertanam atau garis bimbingan atas |

| Jenis pemacu | Electric motor + gear reducer with soft-start control |

| Bekalan Kuasa | Cable drum / low-voltage rail / battery (site-dependent) |

| Sistem Keselamatan | Pengesanan halangan, perlindungan beban berlebihan, hentian kecemasan |

| Pematuhan | Komponen ISO, GB, CE yang disahkan |

Isi borang di bawah untuk mendapatkan akses segera ke katalog kren dan bercakap dengan pasukan teknikal kami untuk rekomendasi semula