ya:

ya:

ku -,, na ya:

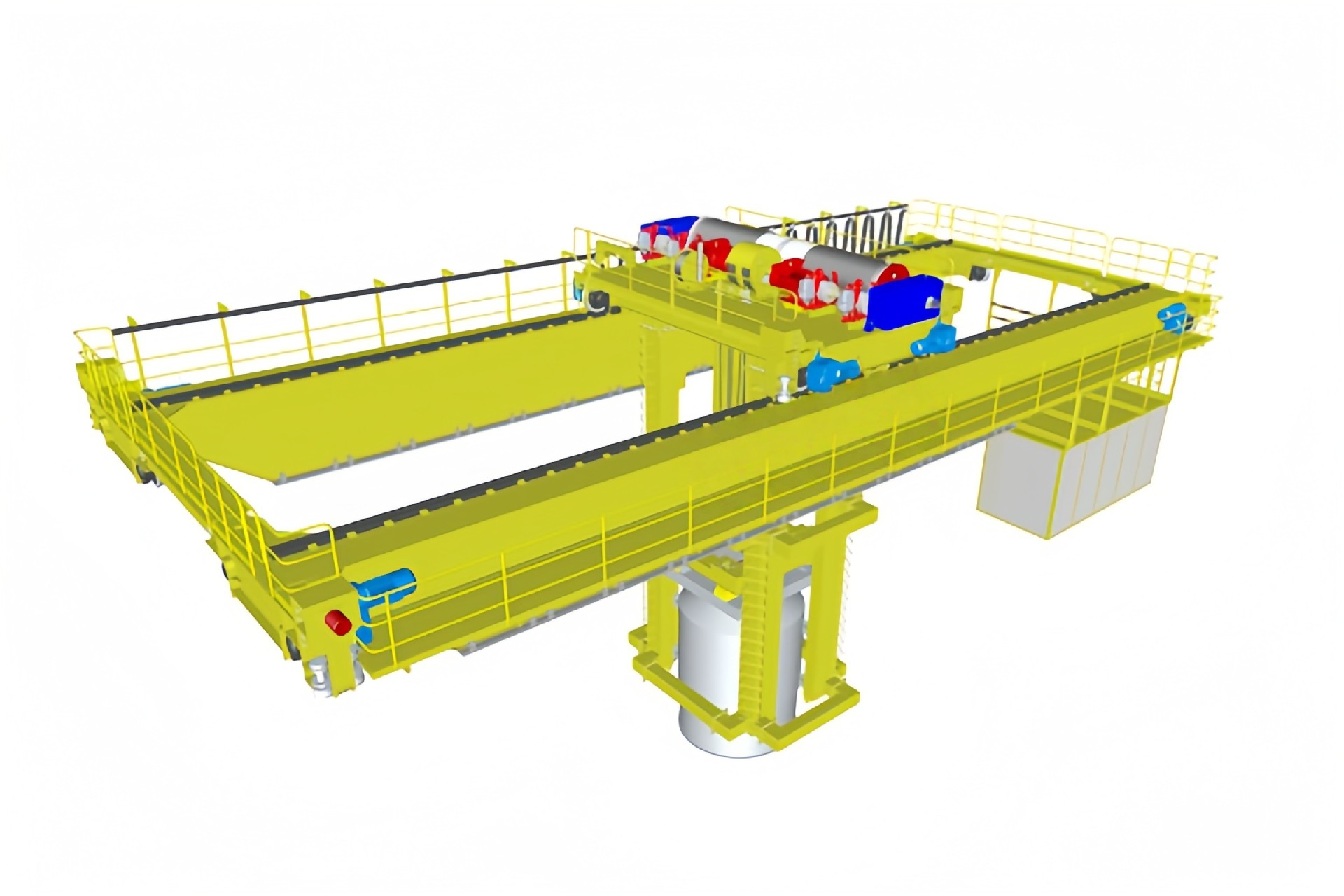

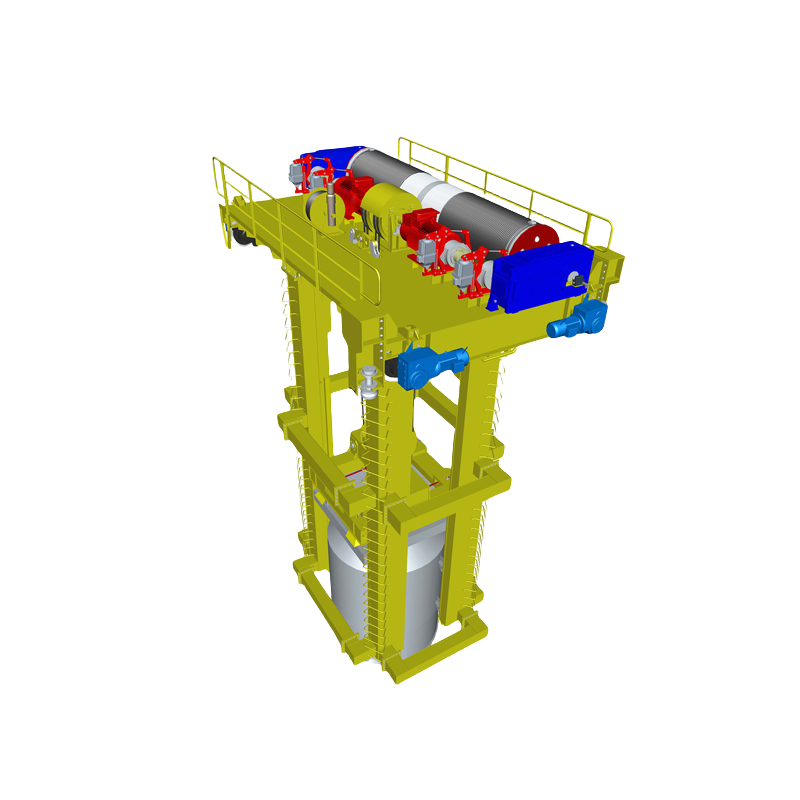

& nbsp; ni Urwego rwo hejuru Sisitemu, ya: i, Ibisabwa - Nka ejuru - Ubushyuhe, Kinini KIGEZWEHO, Amashami:, na -.

ejuru -, Ihangagishusho, na A & nbsp; Kuri Urufunguzo Ibikorwa, Akazu Imiterere, na Birenzeho. ku Hejuru:, A Inshingano in Bikomeye,, na Ibikorwa: muri.

| Umumaro | Custom-configured (typically 10–74 tons) |

| Iboneza | - Imigaragarire |

| Bidasanzwe | Tool Trolley (hook-type lifting);Aluminum Extraction Trolley (with insulated, anti-sway hook & weighing system);Feeding Trolley (with hopper, discharge system & electronic measuring unit) |

| 8 Ipine Porogaramu- shoboza Na: 3. in 1. | |

| Igenzura | Cabin control + remote diagnostics |

| Ubugari | Anti-corrosion materials + sealed electronics |

| Na: ya: Ubushyuhe Ibisabwa | |

| , ISO - |

in i Ifishi% S: munsi Kuri Kubona By' ako kanya Kuri i Agatabo na Kuri ya: