Crane Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry

Crane Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry Gantry

Bagi mereka yang memerlukan kebolehpercayaan. Dibina untuk tugas berat, dibina untuk terakhir.

Dengan lebih daripada 20 tahun dalam industri kren, Henan Mine tahu dengan tepat apa yang penting kepada pelanggan: prestasi yang stabil, masa henti yang rendah, penyelenggaraan yang mudah, dan keupayaan tugas berat yang sebenar.

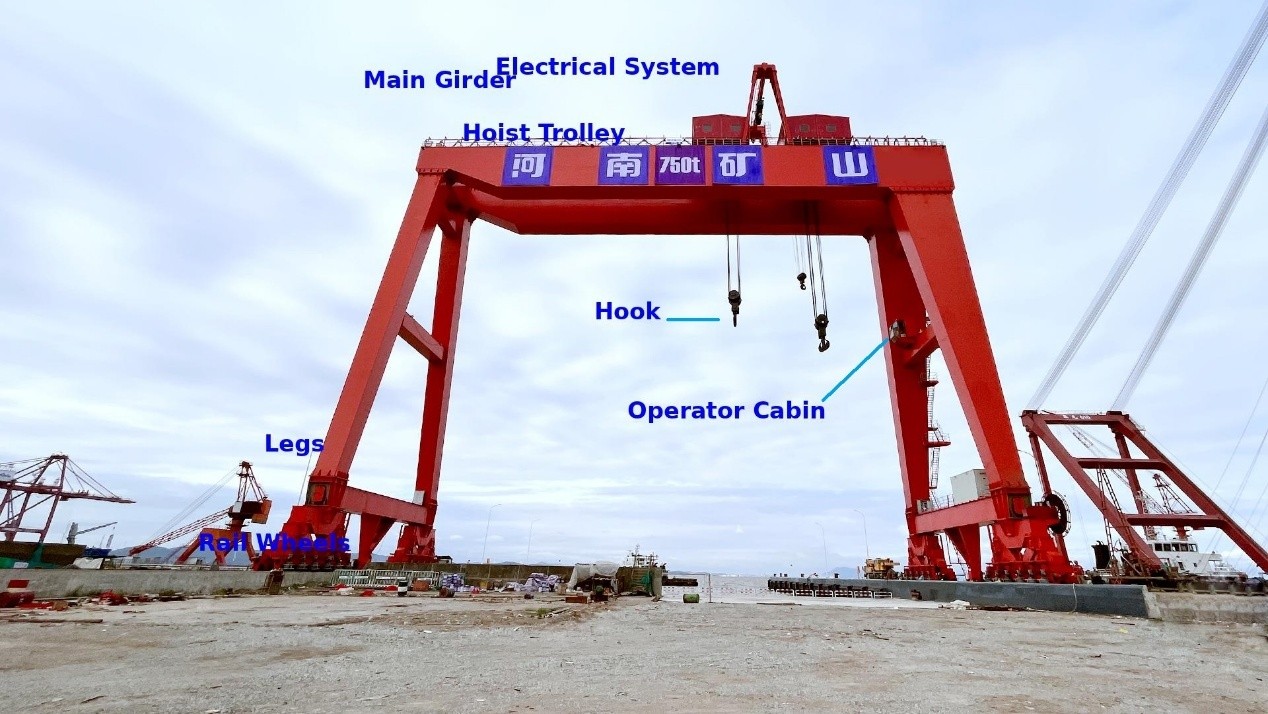

Kren gantri ganda kami & nbsp; direka untuk perusahaan yang beroperasi di bawah beban kerja yang intensif, persekitaran yang mencabar, dan tarikh akhir yang tidak memaafkan. Sama ada anda mengangkat 20 tan keluli struktur di luar angin, atau berjalan 24/7 di stesen makanan relau, kren ini direka untuk berfungsi tanpa kompromi.

Kami telah melihat kegagalan yang disebabkan oleh struktur yang kurang besar, pendawaian yang tidak konsisten, atau angkat yang kurang berprestasi. Itulah sebabnya setiap kren lombong Henan dibina mengikut spesifikasi perindustrian dunia sebenar, bukan hanya keadaan ujian.

| Spesifikasi | nilai |

| Kapasiti beban | 5 - 1000 tan |

| Melayu | 18 - 36 meter |

| Tinggi mengangkat | 6/9/12 meter atau disesuaikan |

| Tugas Kerja | A3 – A8 (continuous, heavy-duty) |

| Bekalan Kuasa | 220-690V, 3ph, 50-60Hz |

| Syarat persekitaran | -25℃ to +45℃, humidity ≤85% |

| Kawalan | gantung / jauh tanpa wayar / kabin |

Isi borang di bawah untuk mendapatkan akses segera ke katalog kren dan bercakap dengan pasukan teknikal kami untuk rekomendasi semula