防爆自动化洁净室起重机

防爆自动化洁净室起重机

半导体时代的精密起重

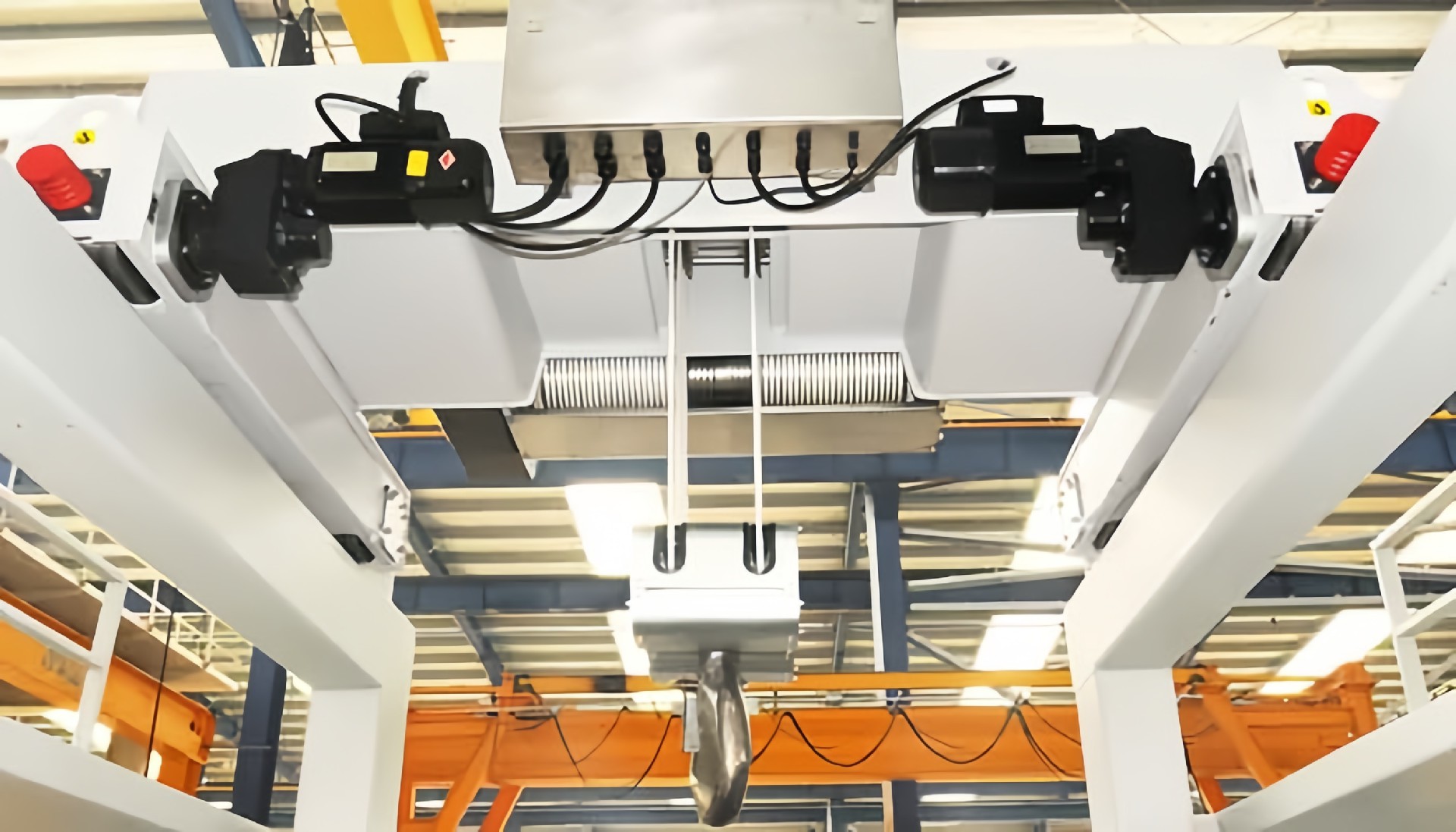

The Henan Mine Explosion-Proof Cleanroom Crane is a high-precision, fully automated lifting system built to meet the strictest cleanliness and safety standards in advanced semiconductor production and microelectronics assembly. Engineered for ISO Class 4 (Class 7 GB) cleanroom environments and certified to dIICT4 explosion-proof standards, this crane is designed to safely handle materials in flammable gas zones without compromising air purity or production efficiency.

凭借集中的计算机自动化、激光定位和完全密封的不锈钢部件,它提供了高速、无污染的提升;具有无与伦比的可靠性。

| 参数 | 规格 |

| 洁净室级 | ISO Class 4 (GB Class 7) |

| 防爆等级 | dIICT4 |

| 控制系统 | 集中式自动化计算机系统 |

| 定位系统 | Laser barcode positioning (trolley & bridge) |

| 操作模式 | Manual / Automatic (switchable & interlocked) |

| 马达型式 | 无风扇、防爆、高防护电机 |

| 材料 | 不锈钢,防静电,密封耐腐蚀 |

| 轴承和;制动器 | 自润滑密封轴承;双密封制动器 |

| 应急安全 | 远程紧急停止,电源故障保持 |

;客户痛点–已解决

| 痛点 | 河南矿山解决方案 |

| 洁净室污染风险 | ✅ ;全密封设计,符合ISO 4级标准的组件 |

| 存在易燃/易爆气体 | ✅ ;经认证的dIICT4防爆起重机结构 |

| 手动操作减缓半导体工艺 | ✅ ;全自动化,集中控制,精确定位 |

| 因维护和故障而停机 | ✅ ;免维护轴承、密封齿轮箱、故障暂停系统 |

| 负载定位不一致,损坏易碎部件 | ✅ ;激光引导小车和桥架行程,精度达到毫米级 |

填写下表,立即访问起重机目录,并与我们的技术团队联系以获得建议