Mlipuko-uthibitisho Automated Cleanroom Crane

Mlipuko-uthibitisho Automated Cleanroom Crane

Usahihi lifting kwa ajili ya Semiconductor Era

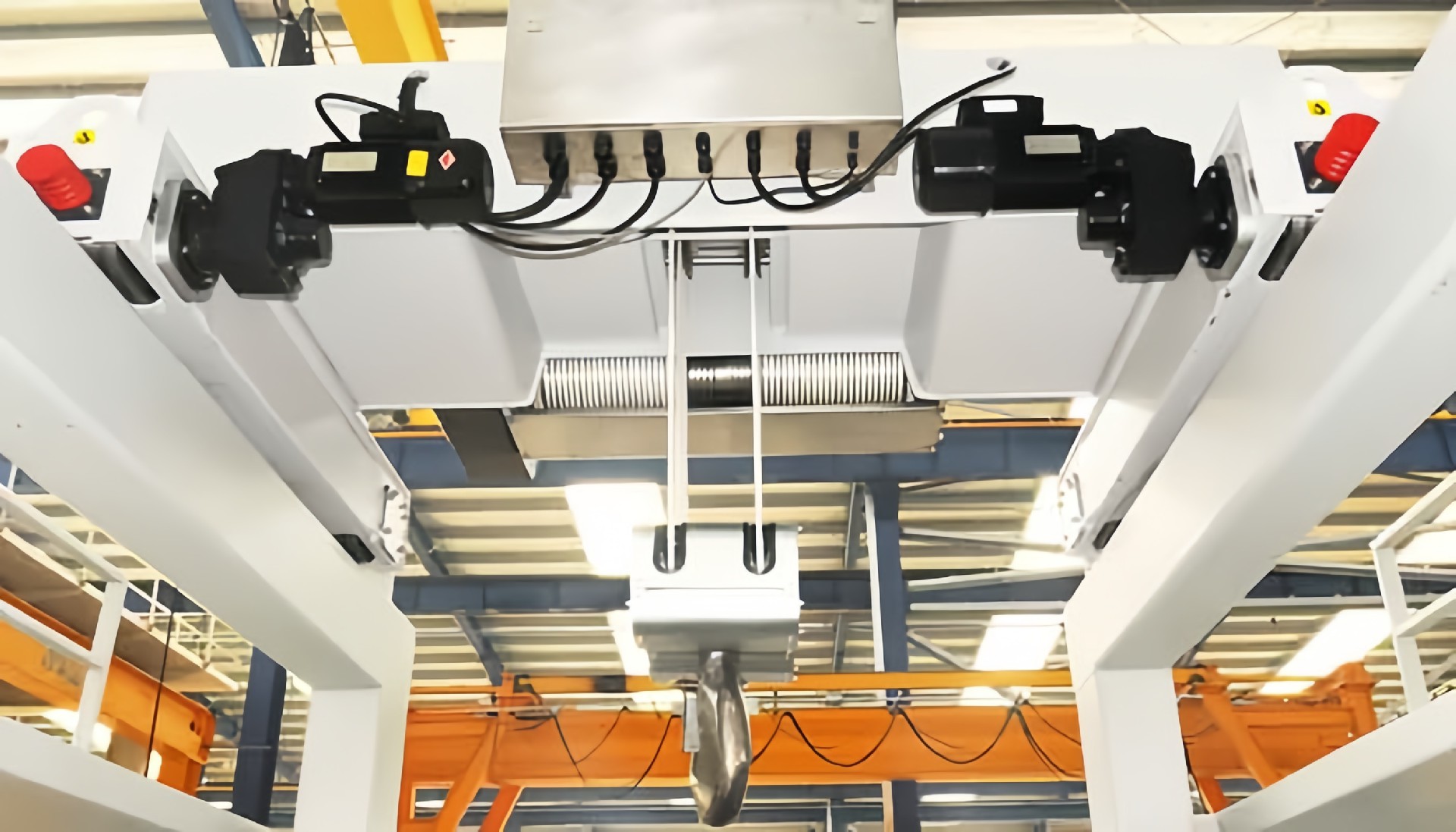

The Henan Mine Explosion-Proof Cleanroom Crane is a high-precision, fully automated lifting system built to meet the strictest cleanliness and safety standards in advanced semiconductor production and microelectronics assembly. Engineered for ISO Class 4 (Class 7 GB) cleanroom environments and certified to dIICT4 explosion-proof standards, this crane is designed to safely handle materials in flammable gas zones without compromising air purity or production efficiency.

Pamoja na automatisering kompyuta ya kati, laser nafasi, na kikamilifu muhuri, vipengele vya chuma cha pua, inatoa kasi ya juu, uchafuzi-bure kuinua kwa uaminifu usiolinganishwa.

| Vipimo | Maelezo |

| Cleanroom daraja | ISO Class 4 (GB Class 7) |

| Rating ya uthibitisho wa mlipuko | ya dIICT4 |

| Mfumo wa Udhibiti | Mfumo wa kompyuta wa moja kwa moja |

| Mfumo wa kuweka nafasi | Laser barcode positioning (trolley & bridge) |

| Njia za Uendeshaji | Manual / Automatic (switchable & interlocked) |

| Aina ya Motor | Fanless, mlipuko-ushahidi, high ulinzi motor |

| Vifaa | chuma cha pua, kupambana na static, muhuri kutu-sugu |

| Bearings & amp; Mabreki | Self-lubricating, kufungwa bearings; brakes mbili muhuri |

| Usalama wa dharura | Remote E-kuacha, nguvu-kosa kushikilia |

Kuhusu Wateja Pain Points SOLUTED

| Maumivu Point | Suluhisho la migodi ya Henan |

| Hatari ya uchafuzi katika vyumba safi | ✅& mfano; Kubuni iliyofungwa kikamilifu, vipengele vya darasa la 4 vya ISO |

| Kuwepo kwa gesi zilizovuka / zilizolipuka | ✅& mfano; Kuthibitishwa dIICT4 mlipuko-ushahidi crane muundo |

| Manual kushughulikia kupunguza michakato semiconductor | ✅& mfano; Automation kamili na udhibiti wa kati na nafasi sahihi |

| Kuzima kwa sababu ya matengenezo na kushindwa | ✅& mfano; Bearings bure matengenezo, gearboxes muhuri, kosa kuweka mfumo |

| Unconsistent mzigo nafasi kuharibu vipengele dhaifu | ✅& mfano; Laser-kuongozwa trolley na daraja kusafiri na mm-kiwango usahihi |

Jaza fomu hapa chini ili kupata upatikanaji wa haraka kwa cranes orodha na kuzungumza na timu yetu ya kiufundi kwa ajili ya recommendations