- Gantry Cranes: From definition to selection, this is the all-round assistant for industrial lifting.

-

Release Time:2025-12-12 13:49:44Share:

Gantry Cranes: From definition to selection, this is the all-round assistant for industrial lifting.

Lifting operations are really important in lots of different industries, like industrial production, logistics, warehousing, port terminals, construction sites and so on. They're basically the connection between all the different production processes. Gantry cranes are really important pieces of kit because they can be used for lots of different things and they can bear a lot of weight. But a lot of people often have questions like, "What even is a gantry crane?", "Which one is best for the job?", and "How do you pick the right one?" This article gives you all the info you need on gantry cranes, from the basics to the practical. You'll learn how to get to grips with the main ideas and figure out exactly what equipment you need.

I. Core Answer: So, what actually is a gantry crane?

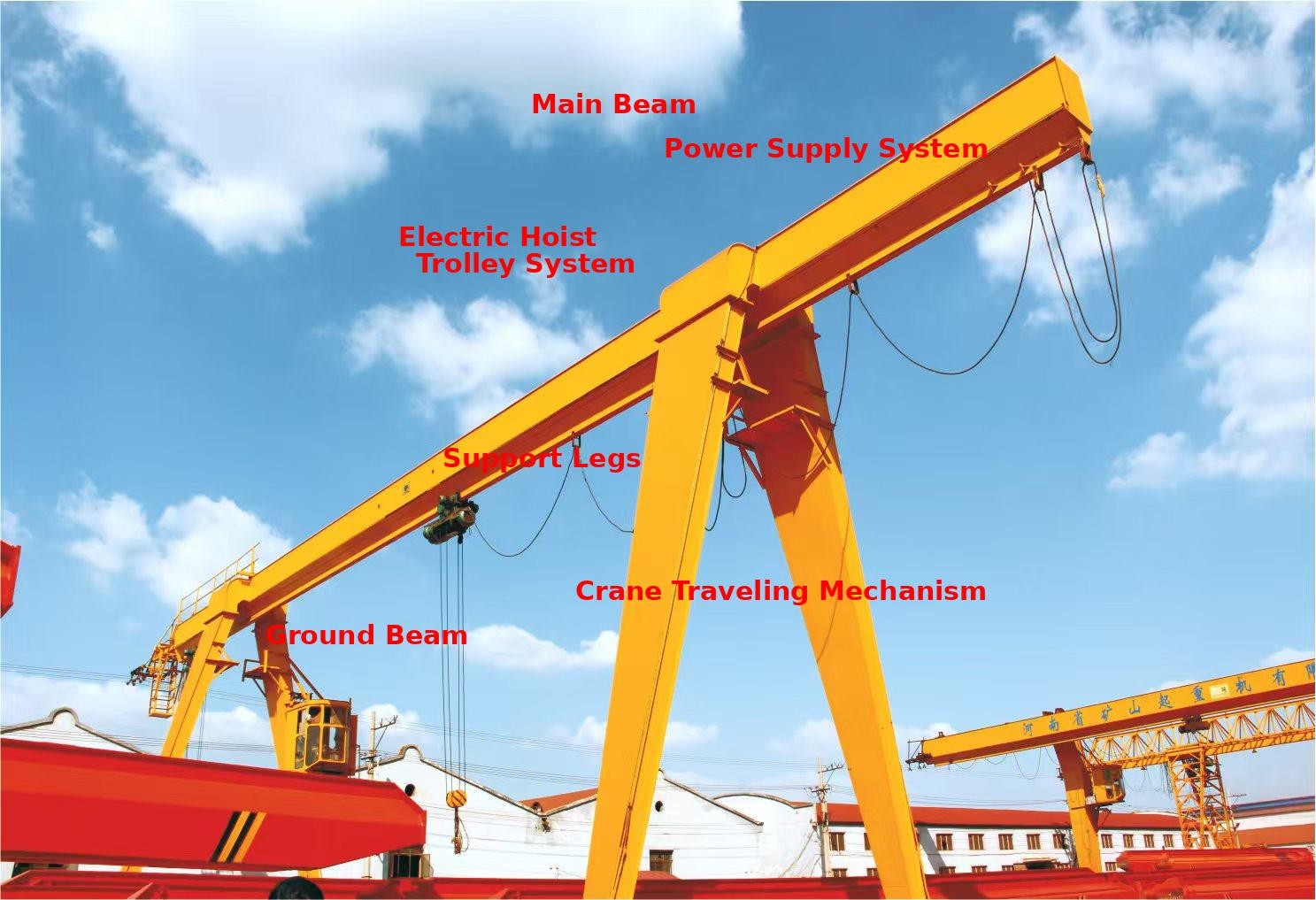

A gantry crane, also called a portal crane, is a special piece of kit that uses a portal frame structure to lift and transport heavy loads. The main parts of the machine are the main beam, outriggers, hoisting mechanism, travel mechanism, and control system. Gantry cranes are a bit different from bridge cranes because they don't need to be attached to the factory steel structures. They move along the ground rails, giving you free rein to work anywhere outside the factory. This means they can be used on their own in open-air yards or as part of production processes along workshop edges. That's why "general-purpose gantry cranes" and "outdoor gantry cranes" are often searched for in the industry.

The gantry crane's main selling point is its "full-space operational capability" – the main beam spans the work area, with outriggers on both sides supported by ground rails. The trolley moves along the main beam, working with the hoisting mechanism to lift, lower, and move loads horizontally, creating a three-dimensional working space. They can lift anything from 0.5 to 500 tons and are used for all kinds of things, from moving light cargo to hoisting heavy equipment. This makes them essential for "industrial gantry cranes" and "heavy-duty gantry cranes."

II. Detailed Classification: Here's the lowdown on the main types and uses of gantry cranes, all customised to fit your needs.

Gantry cranes come in all sorts of types, and they're all different in how they're built and how they perform. It's really important to be precise about how you categorise things, especially when it comes to selection. Here, we'll go through the different types of gantry cranes and when to use them, based on three main things: how they're built, what they're used for, and how they're controlled. This should help you find the right one quickly.

1. Classification by Structural Form: This is how we figure out how well something performs and how well it works with other things.

Single-girder gantry cranes: They've got a simple structure, are lightweight and low-cost, and they come in a box-type or I-beam girder. Lifting capacities usually range from 0.5 to 50 tons, with duty classes A1-A5. It's perfect for light-duty lifting jobs like in small cargo yards, workshop auxiliary areas, and for handling building materials. 'Single-girder gantry crane selection' and 'small single-girder gantry crane' are typical long-tail keywords.

A crane with two girders. It's got two parallel box girders for better bending and torsional resistance, a high load capacity (10-500 tons) and duty classes A3-A8. It's perfect for heavy-duty lifting jobs like handling steel billets in mills, container loading/unloading at ports, and large equipment maintenance. There's a lot of interest in "double-girder gantry crane procurement" and "heavy-duty double-girder gantry crane."

Semi-Gantry Crane: It's got support legs on one side only, with the other side supported by factory columns or wall-mounted rails. It's got the working range of a gantry crane and the space efficiency of a bridge crane. It's perfect for lifting in factory extension areas or confined spaces, like the interface between machinery workshops and cargo yards. The main application terms include 'semi-gantry crane applications' and 'workshop semi-gantry cranes'.

Mobile Gantry Cranes: These cranes don't need fixed tracks because they use tyre-mounted chassis, which lets them move around easily and operate outside of track constraints. Great for lifting stuff temporarily and for building sites and emergency power repairs. People often search for things like "mobile gantry crane rental" and "portable gantry crane".

2. By Application Purpose: Let's talk about specialised work requirements.

Gantry cranes that can be used for all kinds of jobs: Just the basics, no special custom features. It's great for scenarios where there's no need for high-temperature, corrosive, or explosion-proof requirements, like in carton packaging and steel/profile material handling. These are the best low-cost gantry cranes out there, usually rated A1-A5.

- Metallurgical Gantry Cranes: These cranes are engineered for metallurgical industries, so they can handle high temperatures, dust and impacts. They've got high-temperature-resistant motors and insulated protective covers, so they can handle molten steel ladles, ingots and other heavy loads. Their duty cycle is A6 minimum. The cranes are called a "metallurgical workshop gantry crane" and a "high-temperature-resistant gantry crane" because they're designed for specific tasks.

Explosion-proof gantry cranes are a must. It's perfect for areas where there's a risk of fire or explosion, like in chemical, pharmaceutical, and oil and gas industries. All the parts have explosion-proof designs so there's no chance of sparks. They're classified by explosion-proof ratings, like ExdⅡBT4 and ExdⅢCT6. There's a lot of demand for "chemical explosion-proof gantry cranes" and "explosion-proof gantry crane selection."

- Container Gantry Cranes: These cranes have special container spreaders that let them move stuff around really accurately, with lifting capacities of between 40 and 100 tons. They're mostly used in ports and container yards, and their main uses are "container gantry cranes" and "dock gantry cranes."

Shipbuilding Gantry Cranes: These cranes can lift really high (more than 50 metres) and handle ship sections and large marine equipment. They've got anti-sway devices, so they can handle the tricky conditions at shipyards. 'Shipbuilding gantry crane' and 'large span gantry crane' are typical long-tail keywords.

3. By Control Method: Getting to grips with how things are done and what's needed.

- Ground-Operated Gantry Cranes: You can control it using ground-level cabs or remote handles, so it's really easy to use. It's perfect for areas where you need to be able to get to the crane easily, like small cargo yards. It's cheaper and there's a steady demand for "ground-operated gantry crane".

- Gantry cranes that are operated by overhead cranes: We've made sure to include an operator cabin on the main beam, giving you a great, unobstructed view of the work area. These cranes are perfect for lifting in big, complicated environments like ports and steel mills. They're also known as "overhead-operated gantry cranes."

- Smart Remote-Controlled Gantry Cranes: It's great for wireless remote operation or PLC automation, so you can run things without having to be there and it'll make things safer. This is the way things are going for "intelligent gantry cranes," which are perfect for high-risk, high-frequency operations.

III. Scientific Selection: 5 steps to getting your Gantry Crane procurement right and avoiding common mistakes

Gantry cranes are expensive to buy and last a long time. If you get the selection wrong, you can end up with inefficiency, safety hazards or even idling equipment. With our years of industry experience, we can make sure you get the right stuff by picking the 5 core dimensions that are key to "safety, efficiency, and operational suitability."

1. So, first things first: let's define the core parameters to lay the foundations for selecting the right options.

The core parameters will tell you straight away if the equipment meets the operational requirements. Try to get clear on three things: Firstly, let's look at the lifting capacity. Decide on the maximum weight that can be lifted in one go, plus add a margin of 10–20% (so for a 50-ton cargo, choose equipment that can lift 60 tons). This will help to prevent damage or accidents caused by overloading.

(b) Span and Lifting Height: Span should match the width of the operational area (e.g. yard width, workshop span). The lifting height needs to be enough to reach "ground level to the highest storage point/working height + 1.5 metres safety margin" to avoid collisions with buildings, pipelines or other equipment.

3) Duty Cycle: Just pick based on when they're open: Light Duty (2 hours max) – A1-A4; Medium Duty (2-4 hours) – A5; Heavy Duty (4-8 hours) – A6-A7; Extra Heavy Duty (8+ hours) – A8. Try not to go overboard or waste resources.

2. Matching Work Conditions: Try not to fall into the "one size fits all" trap.

Different operating conditions mean you need different types of equipment. When you're picking one of these, bear these points in mind:

1) If you're in a high-temperature environment, like in a metallurgy or foundry, you'll need a crane with a motor that can handle at least 200°C and a cooling system.

2) If you're in a flammable or explosive area, like in a chemical plant or oil/gas site, you'll need an explosion-proof crane that can deal with the specific risks of the area.

3) If you're doing outdoor work, like at a port or cargo yard, you'll need wind-resistant equipment, like rail clamps or anchoring systems, and a rain cover to protect against the elements.

4) If you're handling containers, you'll need to think about the hook type (fixed or telescopic) and whether it's compatible with the container truck alignment.

5) If you're in a narrow space, go for a semi-gantry crane to save on space.

3. Site Survey: Making sure the equipment works together

How easy it is to install and operate a gantry crane depends on the site conditions. Before you start buying things, make sure you do a thorough survey: Firstly, the ground load-bearing capacity: The ground under the gantry legs has to be able to support the equipment's weight plus the weight it's lifting. Reinforce with concrete when needed (e.g., pour reinforced concrete foundations for heavy equipment); 2) Rail installation: Make sure there's enough space for the fixed rail installation and maintenance, and avoid putting it in places where it might get in the way of transport routes or other equipment. 3) Spatial constraints: The width and height of the working area have to meet operational requirements, especially making sure there's a minimum clearance of ≥0.5 metres between the main beam and overhead obstacles (like pipelines and lighting fixtures). Things to consider when it comes to the power supply: Make sure you know the voltage (380V/660V/10kV) and the current type (AC/DC) to avoid problems with the motor power.

4. Just make sure you stick to the safety configurations, as we need to keep up our operational standards.

When it comes to lifting operations, safety is always our top priority. We can't compromise on the safety configurations of our equipment. Premium gantry cranes need to have full protective devices: hoisting mechanisms need load limiters (triggering overload alarms and shutdowns) and height limiters (preventing over-hoisting); travel mechanisms need travel limiters (preventing over-travel collisions) and buffers. It's also really important to have emergency stop buttons and overload protection. If you're working on high-risk applications (like metallurgy or in explosion-proof environments), you'll need to make sure you've got supplementary video monitoring, torque limiters and emergency manual control modules. This is all to comply with the "Safety Regulations for Lifting Machinery" (GB/T 6067.1).

5. Choosing reliable manufacturers is key to making sure you get quality and service.

The quality of the equipment and the after-sales service have a big impact on the user experience. When picking manufacturers, focus on three main things: First things first: what are the qualifications? Make sure you focus on manufacturers who have the right "Special Equipment Manufacturing Licenses" and "Installation, Modification, and Maintenance Licenses" to make sure the equipment meets national standards; and then there are the case studies to think about too. Ask for some successful case studies from similar industries (e.g. select manufacturers with steel mill experience for metallurgical applications) to check the suitability of the equipment; 3) Service: Just to let you know, we can confirm the availability of on-site surveys, custom designs and installation/commissioning services. Make sure you're clear about maintenance cycles, how long it takes to get spare parts, and how long it takes to fix something if something goes wrong (we recommend ≤24 hours). This will make sure that customers get the service they paid for.

IV. So, to sum things up: How to get the most out of your gantry crane

When it comes to picking the right gantry crane for your industrial lifting needs, it's not just about grabbing the first one that you see. It's a long-term investment in making sure your production is as efficient as possible and that your operations are safe. So, from working out what a gantry crane is to getting to grips with how to classify them based on their structure, how they're used and how they're controlled, and then making smart decisions based on five key things — like core parameters, how they're used, how the site is laid out, safety and who made them — each step helps businesses avoid picking the wrong gantry crane and make sure they're compatible.

If you're struggling with "gantry crane selection challenges" or need customised equipment solutions that are right for your specific working conditions, get in touch with professional manufacturers at any time for one-on-one consultation services. Gantry cranes can be your best friends when it comes to upping your production game and keeping things safe and sound.