- What's a smart crane for distilleries?

-

Release Time:2025-12-08 17:28:52Share:

What's a smart crane for distilleries?

In the fermentation and storage workshops of strong-aroma and soy-sauce-aroma liquor producers, 500-kilogram clay jars, 2-ton stainless steel barrels, and stacked piles of fermentation starter material are constantly being moved around. But problems like small workshop spaces, flammable and explosive alcohol vapours, and fragile jars often mean that traditional lifting equipment doesn't work well. Mistakes when positioning can cause jars to crash into each other and break, and there are safety problems with motor sparks. Plus, it's just not efficient to use it manually.

I. Core Definition: The Distillery Smart Crane

The distillery smart crane is not just an ordinary crane with a few extra features. It's a smart lifting device that's been customised for the specific conditions you find in distilleries, like flammable and explosive environments, humidity, heavy loads and precision handling. It's built on top of lifting machinery and includes explosion-proof systems, intelligent positioning modules, remote control systems and fault warning systems. This makes it easy to lift and place materials like wine jars, barrels, and fermentation cakes, while also making things safer and reducing the need for manual labour thanks to smart technology. It's great for all sorts of operations, like fermentation areas, storage cellars and bottling lines.

Its main difference from regular distillery cranes is that it's both "intelligent and explosion-proof". Normal equipment relies on people to do the positioning manually, which often leads to more than 5% of jars breaking. On the other hand, the Distillery-Specific Intelligent Crane uses laser positioning to line things up to within millimetres, which means less breakage – less than 0.1% in fact. At the same time, explosion-proof motors and sealed electronic control systems get rid of any safety worries in places where there might be alcohol vapour, so they're the top choice for breweries when it comes to upgrades.

II. A Complete Guide to Brewing Smart Cranes

When it comes to brewing smart cranes, it's all about understanding the specific needs of the brewery. These cranes are split into different categories, each one suited to a particular task, like moving koji, lifting wine jars, or helping out with bottling. Knowing the right crane for the job is crucial, so let's dive in and get to know these cranes a bit better.

1. Classification by function and purpose

Wine jar transport intelligent crane for distilleries: It's made especially for clay and porcelain jars, with curved anti-slip lifting attachments to stop the jars from slipping when you're lifting them up. Integrated load cells show you the real-time jar weight, making it perfect for transporting jarred liquor in sauce-aroma liquor distillery storage warehouses. It can lift anything from 0.5 to 5 tons, so you can be sure of a tight connection between racks and transport carts.

Wine Yeast Handling Intelligent Crane: It's got adjustable grab attachments so it can handle different sizes of yeast stack. The graded lifting speed control (fast empty hook, slow loaded hook) stops the yeast from scattering. This is often used in places where strong-aroma liquors are fermented, to help transfer yeast from storage to fermentation tanks efficiently.

Wine plant filling line auxiliary intelligent crane. It's a compact, single-girder design that's great for narrow filling workshop spaces. His main job is loading and unloading stainless steel barrels. It links up with the filling equipment using smart linkage systems to boost productivity on the brewery filling line.

Smart Cranes for Raw Material Handling in Breweries: They're designed for brewing ingredients like sorghum and wheat, and they've got hydraulic grabs for rapid bulk material pickup and unloading. Integrated dust covers stop ingredients getting spread around, making them great for loading and unloading in big warehouses where brewery raw materials are stored.

2. Classification by Structural Form

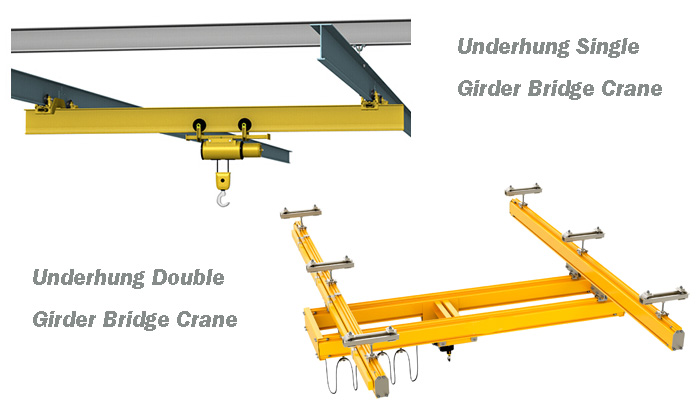

Single-girder intelligent crane for distilleries: It's got a single main girder structure, which makes it lightweight and compact. You can customise the span from 8 to 16 metres, and the lifting capacity ranges from 1 to 10 tons. It's perfect for narrow distillery workshops and small storage spaces, like moving liquor jars in artisanal baijiu workshops. It can manoeuvre easily between columns.

Winery Double-Girder Intelligent Crane: The dual-girder load-bearing design makes it really stable. It can lift between 5-20 tons. Span: 12-25 metres. It's perfect for big-time operations in big winery fermentation and storage workshops, like moving 2-ton stainless steel barrels over long distances. The double-girder design makes it pretty stable when you're lifting it.

Mobile Intelligent Crane for Distilleries: It doesn't need any fixed tracks, it's got a tyre-mounted chassis with an intelligent steering system. It can move between fermentation areas, storage cellars and bottling workshops. The Temporary Mobile Intelligent Crane for Distilleries is perfect for the needs of small and medium-sized distilleries, no matter where they are.

Winery L-Shaped Intelligent Crane: One side of the outriggers is installed flush against the wall, saving floor space. It can be used in areas next to walls in wineries. It makes it easy to move wine vats from racks on the wall to transport vehicles, so you don't have to worry about stuff hitting the walls.

3. Classification by Intelligent System

Precision Positioning Intelligent Crane for Wineries It combines laser positioning and visual recognition systems, with a positioning accuracy of ±2mm. It automatically aligns jars with rack slots during placement. This setup is used by lots of high-end baijiu distilleries, and it really cuts down on the number of jars getting damaged.

Winery Remote-Controlled Intelligent Crane: It supports dual-mode operation via 5G remote control or local operation. Operators can do the whole process—lifting, moving, and positioning—from the central control room, so they don't have to go into damp, alcohol-filled cellars. This system is often used in winery cellar intelligent cranes to make sure that people are safe.

Wine Cellar Fault-Alert Intelligent Crane: Real-time sensors keep an eye on how worn out the wire rope is, how hot the motor is, and how well the brakes are working. If something unusual happens, you'll get an immediate alert on your phone. This system reduces unexpected downtime for high-frequency operation intelligent cranes in wineries.

Winery Data-Integrated Intelligent Crane: Puts info about the type of material, weight and when it's been transferred into winery ERP systems, and automatically logs it. Then it can generate operational reports. Large-scale winery intelligent cranes improve production efficiency by using data to make management decisions.

4. Classification by explosion-proof rating

Ex d IIB T4-rated Distillery Smart Crane: It's perfect for places like fermentation zones and low-alcohol storage warehouses. Its explosion-proof motor and control box can handle flammable/explosive environments caused by alcohol vapour, making it the go-to choice for most distilleries. These general-purpose explosion-proof smart cranes for distilleries meet this rating.

This Distillery Smart Crane is Ex d IIC T6-rated, which means it's got a higher explosion-proof rating. So it's perfect for those high-risk scenarios, like storing high-proof liquor in warehouses and alcohol blending workshops. It resists high-concentration alcohol vapours. High-proof liquor distilleries use smart cranes to make sure they get this type.

III. The main benefits of Distillery Smart Cranes

Distillery Smart Cranes are great because they deal with all the problems distilleries have by offering advantages that are especially good when compared to traditional equipment.

1. Explosion-Proof Safety

The standard setup includes explosion-proof motors, buttons and sealed cables. And with anti-electric leakage and anti-spark designs, they're safe to use even in places where there's a lot of alcohol. When we put it into action at a liquor company in Henan, it totally got rid of the "motor sparks" that traditional cranes were producing, and passed the special inspection by the safety guys.

2. Precision damage reduction

Laser positioning and variable-frequency speed control make sure you can lift and place wine vats smoothly and precisely. So, after the company started using the Precision Positioning Intelligent Crane for Distilleries, the damage rate to their liquor transport went down from 8% to 0.05%. That's meant savings of almost one million yuan a year in lost liquor and ceramic vats.

3. Smart efficiency

With remote control and automatic operations, one operator can handle two devices at once. This increases efficiency by 60% compared to manual methods. When we put this system into place at a brewery, it cut the time it took to load a stainless steel keg from 10 minutes to just 3 minutes per keg. This meant that the brewery could increase its daily production capacity by 30%.

4. It's durable and moisture-resistant

The main beams and legs have galvanized and anti-corrosion coating treatment. Electrical control boxes meet IP65 protection standards, meaning they can handle cellar humidity. The lifespan of the equipment is between 8 and 15 years (for traditional cranes), which means maintenance costs can be reduced by 45%.

IV. Here are some typical application scenarios:

Strong-aroma liquor distilleries: Use Ex d IIB T4-rated smart cranes for moving koji in fermentation zones and 5-ton precision-positioning smart cranes for handling liquor jars in storage areas. This will make sure that koji transfer and liquor jar lifting operations are safe and efficient.

Liquor distilleries that use soy aromas: Use remote-controlled wine jar smart cranes in cellars to stop staff going into humid environments; use single-girder smart cranes on filling lines to load stainless steel barrels quickly.

Brewery: Warehouses use grapple cranes to handle raw materials, while bottling lines use data-linked cranes to integrate with production systems for automated transfer.

We're running some small-scale liquor workshops. Go for 2-ton mobile distillery intelligent cranes, which are flexible and can be used in different areas without needing to install fixed tracks first, so you don't have to spend as much money up front.

V. Key things to think about when choosing intelligent cranes for distilleries

Work out what you need the cranes to do: So, to avoid over-engineering, you just need to work out the core parameters based on stuff like 'maximum lifting capacity' (e.g. 1-ton model for 500kg wine jars), 'workshop span' (e.g. 12-meter span for 10-meter workshops) and 'application scenario' (go for explosion-proof models for fermentation zones).

Please can you check that Explosion-Proof and Smart Certifications have been verified? Some of the manufacturers we work with have Explosion-Proof Electrical Equipment Certification and Special Equipment Manufacturing Licenses. It's really important that smart systems provide field test reports that show how accurate they are and that they work properly.

Focus on local services: Try to pick manufacturers with service centres locally or nearby. Henan wineries should check out Henan KuanShan Winery Smart Cranes, which offer a 2-hour emergency response to fix equipment quickly and prevent production issues.

So, to sum things up: Smart Cranes for Distilleries – Vital Upgrades for Wine Businesses

The main selling point of smart cranes for distilleries is their special design. Their explosion-proof construction makes them safe, smart technology makes them more efficient, and they can be customised to fit any site. They really hit the nail on the head in terms of the industry's main problems, like the risk of breakage from heavy loads, the potential hazards of flammable materials, and narrow spaces causing blockages. From moving fermentation starters to lifting fermentation vats, from fermentation zones to bottling lines, the different types of equipment are exactly right for the job, becoming essential for scaled production.

As a top global supplier of cranes, Henan Mine Crane has a wide range of products from 5 to 500 tons. We'll provide custom designs based on site drawings, load characteristics and environmental parameters. Our full lifecycle services offer all-in-one solutions, from site surveys and design planning to installation and commissioning, plus regular maintenance.

Email:infocranehenanmine.com