- Grab Crane Selection Guide for Waste Treatment Plants: Right stuff for the job, making waste treatment plants run like clockwork

-

Release Time:2025-11-04 11:37:08Share:

Grab Crane Selection Guide for Waste Treatment Plants: Right stuff for the job, making waste treatment plants run like clockwork

Waste treatment plants are a busy place, so it's important to have the right materials and equipment to keep things running smoothly. Grab cranes are really important for dealing with all sorts of materials, like huge amounts of raw mixed waste, sorted recyclables, fermented biomass, and high-calorific-value derived fuels (RDF/SRF). It's like a giant arm for the industrial workplace, handling demanding tasks like loading, unloading, transferring, stacking and feeding. Picking a high-performance grab crane that's just right for the job can really boost how efficiently the plant runs, keep costs down, and make things safer.

I. Let's take a closer look at how things are going at the waste processing plant.

If you're looking for a grab crane for a waste processing plant, you need to understand its demanding environment and unique requirements:

Complex Material Characteristics: Waste is made up of all sorts of different components, and they can vary a lot in terms of density, and some of them can corrode and generate combustible gas.

Extreme Environmental Conditions: It's humid all year round, there are corrosive acidic gases, a lot of dust and big temperature changes.

High-Intensity, Precision-Critical Operations: You'll need to be using it 24/7 for grabbing, lifting, moving and precise material placement/stacking tasks.

Strict safety requirements: This equipment needs to be really reliable and safe, especially when it's being used in places where there could be explosive gases.

II. Here's a full rundown of the main grab crane types out there.

To deal with all kinds of waste handling needs, the market has loads of different grab crane options. Here are some of the most common types of waste treatment facilities:

By Grab Drive Method:

Electric Wire Rope Grab Cranes: This is the most common type in waste management. The grab's opening and closing is driven by an independent hoisting wire rope drum. This is a reliable structure that's easy to maintain and great at dealing with complex, bulky mixed waste.

Hydraulic Grab Cranes: These cranes use hydraulic systems to open and close their grabs, either integrated or external. They've got a lot of closing force, you can control them really well, and they're great at handling materials. They're perfect for compacted, heavy materials or anything that needs a lot of crushing force. They're small but they need a lot of maintenance because of their hydraulic systems.

By Structural Type:

Gantry Grab Cranes: These cranes have a gantry structure that spans the tracks, and they usually cross the rails along both sides of a yard. Their wide coverage makes them perfect for stacking, retrieving and mixing operations in large waste yards or storage pits. Models with rotating mechanisms are more flexible.

Bridge Grab Cranes: The bridge girder of these cranes runs on tracks supported by columns on both sides of the facility, with a trolley moving horizontally along the girder. They're perfect for precise loading, unloading and feeding operations in fairly confined spaces. Bridge grab cranes are great for making the most of small spaces.

By Application and Function:

Waste Handling Cranes: It's specifically designed for waste storage pits in incineration plants, transfer stations, or large landfills. Their main jobs are waste stacking, agitation, mixing, and feeding into incinerators. These cranes tend to be pretty resistant to corrosion, and they often come with built-in weighing systems, automatic fire suppression, and explosion-proof designs. This makes them safe to use in areas where there might be explosive gases.

Ash Grab Cranes: You might also know them as slag grab cranes. They work in areas where slag is handled after it's been incinerated. They're used to grab and move around slag that's been heated up or cooled down. These cranes have to be able to handle intense heat, radiation and abrasive slag, often with special heat-resistant grabs and protective designs.

Scrap Metal Grab Cranes:

These cranes are the heavy-duty ones that work at the back of waste sorting lines. They're great at handling sorted heavy and bulky recyclables, like big metal pieces and scrap car bales. They need to be able to grip really well and last a long time.

Biomass/RDF Grab Cranes:

These cranes are used for handling crushed, dried biomass or solid recovered fuels (RDF), so it's important to take steps to prevent dust explosions.

III. Here are the main things to think about when choosing grab cranes for waste processing plants.

Lifting Capacity and Grab Volume: These are the most important things to consider when it comes to grab cranes. The required rated lifting capacity (including the grab) and grab volume must be calculated based on the volume and density of waste to be handled per cycle to make sure things run smoothly.

Span and Lifting Height: Span depends on the width of the waste storage pit or yard, and the lifting height needs to fit with the maximum stacking height and reach requirements for bottom-of-pit retrieval. You'll also need to think about clearance restrictions within the facility.

Duty Cycle and Intensity: Pick a grab crane that matches the right duty cycle (like A6, A7, or even A8) based on how many hours you think it'll be used each year and the average number of days it'll be working. Waste cranes usually need A7 or A8 heavy-duty models.

This is the corrosion protection grade. It's really important that critical components (like steel structures, mechanisms and electrical components) are protected against heavy-duty corrosion.

Steel Selection: Weathering or stainless steel materials are recommended.

Surface Treatment: We'll get rid of the rust with a good sandblasting and then apply a top-notch anti-corrosion coating system (like epoxy zinc-rich primer, epoxy micaceous iron oxide intermediate coat, and polyurethane topcoat). You've got to be careful with critical weld areas - they need special treatment.

Protection Rating: Electrical enclosures must achieve IP55 or higher; motors require at least IP54. Travel mechanisms, pulley blocks and so on need to have strong sealing and drainage designs.

Explosion-Proof Requirements: If there are explosive gases like methane, you have to use explosion-proof grab cranes. Make sure you stick to the relevant standards (like GB 3836 and ATEX). Any components that can generate sparks or high temperatures – like motors, electrical control cabinets, limit switches and junction boxes – must be explosion-proof and certified as such.

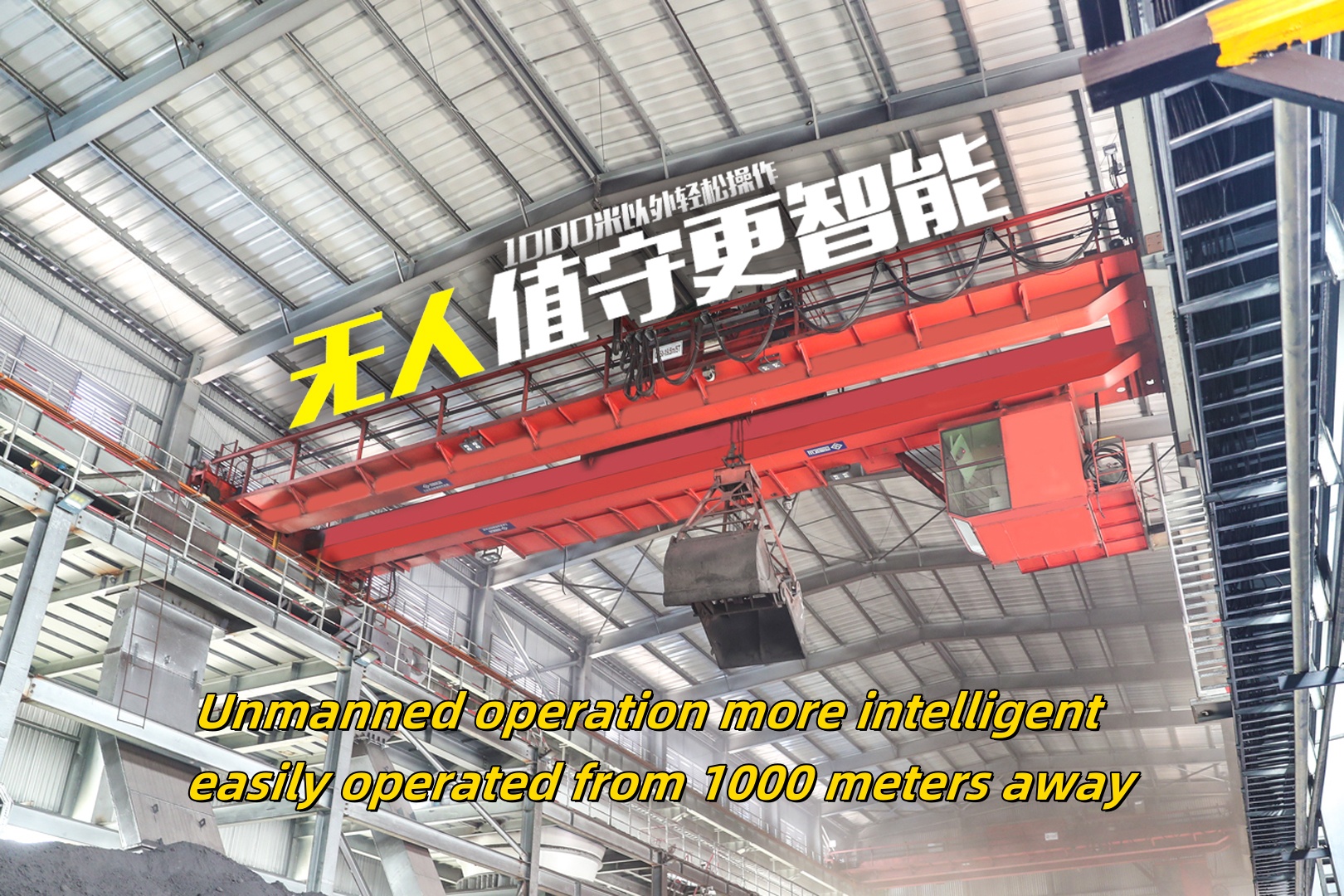

Automation and Intelligent Features: These days, modern waste treatment plants are increasingly opting for automated grab cranes:

Automatic Positioning System: You can also control the positioning of the main/trolley/hoist movements via laser ranging or encoders.

Automatic Grabbing/Dumping System: Laser scanning or visual recognition means you can automate material pickup and get really precise dumping.

Anti-Sway System: It really improves how well things are done and how safe they are.

Remote Monitoring and Diagnostics: It lets you keep an eye on your equipment's health and predict when it might need some TLC.

Here are some safety devices: Grab cranes need to have all the right safety protections, like multiple braking systems, overload limiters, travel limit switches, wind speed sensors, emergency stops, interlock protections and anti-collision systems. In explosion-proof zones, all safety devices have to meet explosion-proof requirements too.

Brand and Service: It's really important to pick a grab crane manufacturer that's got loads of experience and a solid reputation when it comes to environmental protection and waste-to-energy. Have a look at their successful case studies, technical capabilities, after-sales service responsiveness, and spare parts supply capacity.

IV. So, to sum things up: Finding the right stuff for eco-friendly business operations

Choosing the right grab crane for a waste treatment plant is about more than just buying the right equipment. It's a big decision that can have a huge impact. It's got to think about the material, the environment, how it's made, what it's supposed to do, and all the strict rules about safety and the environment. It's really important to understand the technical features and uses of the different types of grab cranes out there, like electric rope grab cranes, hydraulic grab cranes, gantry grab cranes, bridge grab cranes, waste cranes, and explosion-proof grab cranes. It's really important to thoroughly evaluate things like lifting capacity, span, corrosion resistance, explosion protection, and automation.

Investing in a top-notch, long-lasting, and smart grab crane can really boost how efficiently materials are handled at waste processing plants. It can also optimise operational costs, make sure production stays steady and consistent, and enhance safety for people and the environment. A grab crane that's been properly matched to the job can really get the job done for waste processing plants!

As a top global supplier of cranes, Henan Mine Crane has a wide range of products from 5 to 500 tons. We'll provide custom designs based on site drawings, load characteristics and environmental parameters. Our full lifecycle services offer all-in-one solutions, from site surveys and design planning to installation and commissioning, plus regular maintenance.

Email:infocranehenanmine.com

WhatsApp:http://wa.me/8615565218499