- Forgetting the Future: Henan Mine Equips All Cranes with Precision-Engineed Forgotten Wheels

-

Release Time:2025-04-18 20:11:22Partere:

Forgetting the Future: Henan Mine Equips All Cranes with Precision-Engineed Forgotten Wheels

Procedores intelligentes, robustiores exercitus—ushering in a new era of high-efficiency crane manufacturing

Henan Mine Crane

What Happens When You Give a Crane “Invincible Wheels”?

In questionerobustiores, intelligentes et sustinentiores, Henan Mine Crane Co., Ltd. fecit sollicitudinem ante faciendumrotas forged a standard feature across its entire product line—covering all crane types, from gantry and bridge cranes to custom-engineered solutions.

These high-performance wheels, manufactured through an advanced intelligent forging and rolling process, are more than just components—they are the core driver of durability, energy efficiency and product excellence.

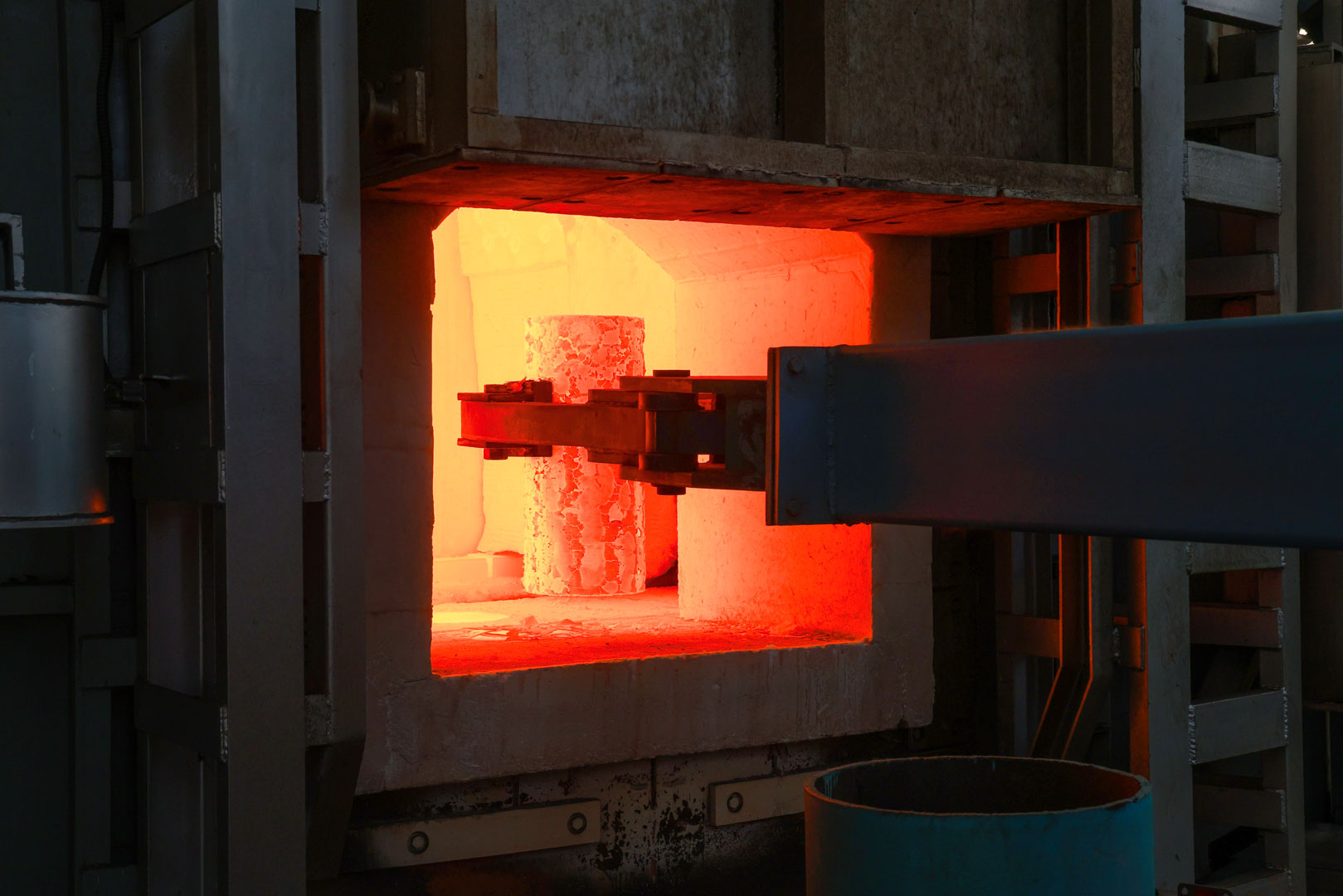

From Raw Steel to Powerhouse Performance

Craftsmanship meets cutting-edge technology

At the heart of Henan Mine's forged wheel production is anProcessum fraudulentium velocitatis integratum qui congregat calefactum, convexionem, fraudulentiam, voluntatem et calefactum in unum fluxum inmundum. High-quality raw materials are subject to immense pressure from a10,000 tonnas fabricantes press, resulting in wheels with exceptional internal strength and refined microstructure.

Haec processus non solum enhavitdensitatem materialem et uniformitatem granorum sed etiam drastically improvet resistentia rotae ad portandum, fatigam et deformationem — crucial pro cranibus operantibus sub alto cargo et continuo cargo cyclibus.

Superior Strength, Extended Service Life

Raedae fabricata Henan Mine liberant:

Excelsior load-bearing capacity

Fortitudinem et fatigam resistentiam improvitum est

Integritate structural fortissima

Lower maintenance frequency and lifecycle costs

For customers, this meansincreased uptime, longer equipment life, and peace of mind in critical operations— whether in steel mills, ports, or energy projects.

Green, Flexible, and Future-Ready

The production line featuresmodular composite equipment, enablingfabricatione flexibilis, alta efficientia. With minimal material waste, low emissions, and reduced energy consumption, the process reflects our commitment togreen manufacturing etlow-carbon development.

Key innovations include:

Multi-station rolling and precision shaping

Minimal machining allowance for high material utilization

Shorter production cycles and lower environmental impact

A Strategic Upgrade to the Entire Industrial Chain

Henan Mine's intelligent forging line is more than just a technical achievement—it's acornerstone of our full-spectrum manufacturing system. It enables:

End-to-end quality control

Procedentia consistentia

Plura flexibilitate ad faciendum praecepta propria

Lower cost per unit through optimized energy use and material flow

Haec investigatio strategica amplius misericordia nostra underscore:industriam crane ad prudentiam, mundatorem et potentiam futuram ducere.