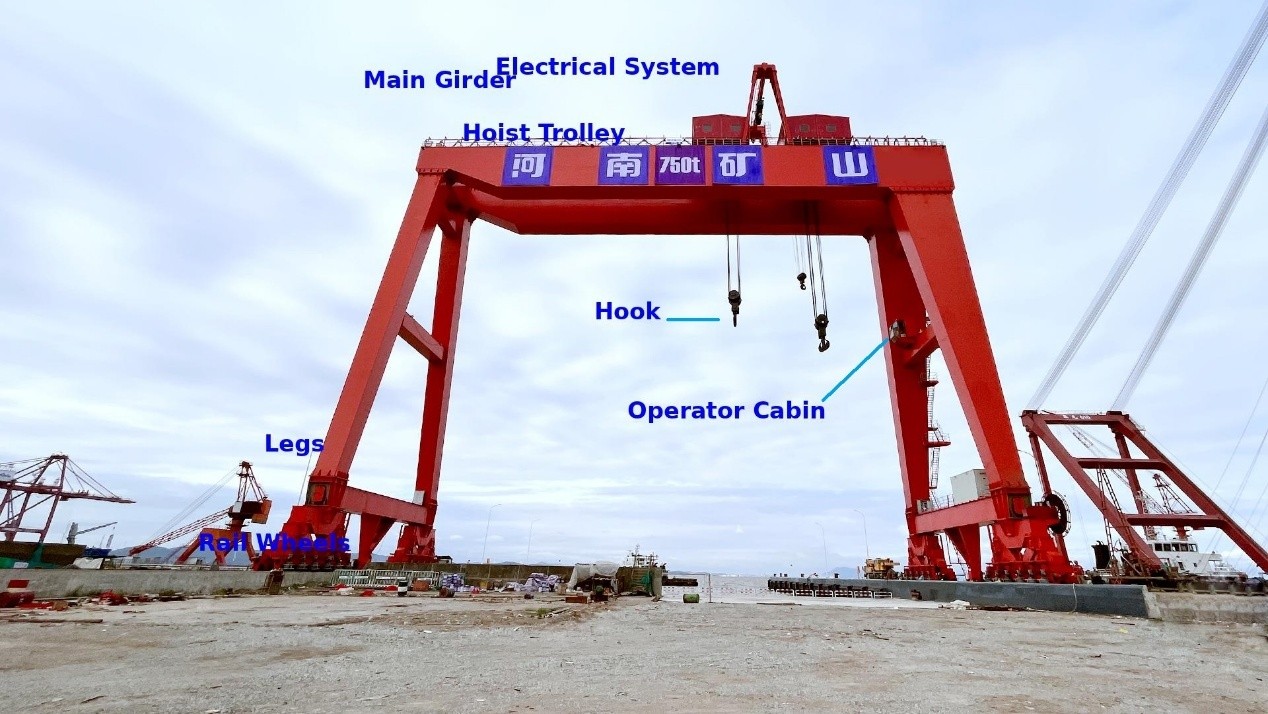

Crane Gantry tal-Girder Doppju

Crane Gantry tal-Girder Doppju

Għal dawk li jitolbu affidabbiltà. Mibnija għal Heavy Duty, Mibnija biex Iddum.

B'aktar minn 20 sena fl-industrija tal-krejn, Henan Mine taf eżattament x'inhu importanti għall-klijenti: prestazzjoni stabbli, ħin baxx ta' waqfien, manutenzjoni faċli, u kapaċità vera ta' xogħol tqal.

Il-krejn tal-gantry tal-girder doppju tagħna hija ddisinjata għall-intrapriżi li joperaw taħt tagħbijiet tax-xogħol intensivi, ambjenti diffiċli, u skadenzi mingħajr ħsara. Kemm jekk qed tħaddem 20 tunnellata ta' azzar strutturali barra fir-riħ, jew qed taħdem 24 siegħa f'stazzjon ta' alimentazzjoni tal-forn, dan il-krejn huwa maħsub biex iwettaq mingħajr kompromess.

Rajna l-fallimenti kkawżati minn strutturi ta' daqs baxx, wajers inkonsistenti, jew lifts li ma jużawx tajjeb. Huwa għalhekk li kull krejn tal-Minjiera Henan huwa mibni skont l-ispeċifikazzjonijiet industrijali tad-dinja reali, mhux biss il-kundizzjonijiet tat-test.

| Speċifikazzjoni | Il-valur |

| Kapaċità tat-tagħbija | 5 – 1000 tunnellata |

| Spanja | 18 – 36 metru |

| Għoli tal-irħiħ | 6/9/12 metri jew personalizzati |

| Id-dmir tax-xogħol | A3 – A8 (continuous, heavy-duty) |

| Provvista tal-Enerġija | 220–690V, 3ph, 50–60Hz |

| Kondizzjonijiet Ambjentali | -25℃ to +45℃, humidity ≤85% |

| Kontrolli | Pendent / Remote mingħajr fili / Kabina |

Imla l-formola hawn taħt biex tikseb aċċess immedjat għall-katalogu tal-krejn u tkellem mat-tim tekniku tagħna għal rakkomandazzjonijiet mill-ġdid