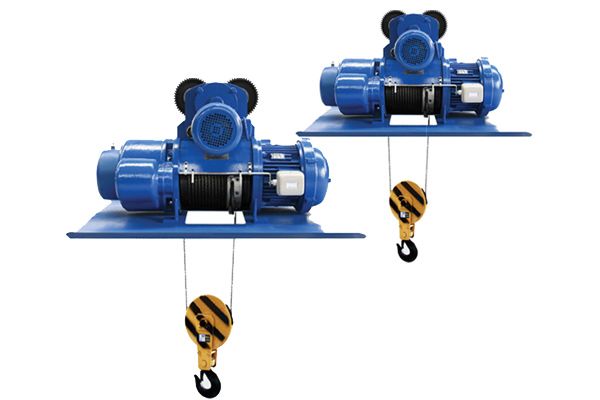

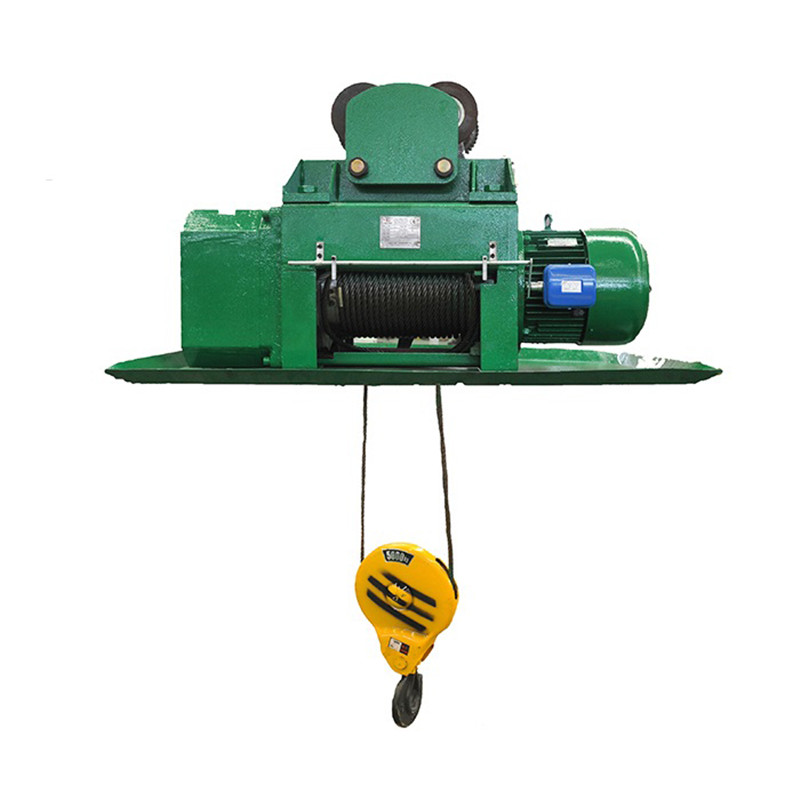

Lift elettriku metallurġiku

Lift elettriku metallurġiku

Inġinerija minn Henan Mine Mibnija għas-Sħana, Iddisinjata għas-Sigurtà

Il-Hoist Elettriku Metallurġiku tal-Minjiera ta 'Henan huwa soluzzjoni ta' irfija ta 'prestazzjoni għolja, mibnija apposta għal ambjenti industrijali b'temperatura għolja u iebsa. Iżviluppat mill-arkitettura affidabbli ta' lifts tat-tip CD/MD, dan il-mudell ġie mtejjeb b'iżolament termali, limitaturi doppji ta' lifting, u karatteristiċi ta' sigurtà msaħħa għal applikazzjonijiet speċifiċi għall-metallurġija.

Ikklassifikat fil-klassi tad-dmir M6, huwa ideali għat-tħaddim tqal u ta' frekwenza għolja fil-fabbriki tal-azzar, il-fonderiji u l-impjanti tat-tidwib. Kemm jekk jimmaniġġja materjal mdawb, komponenti tal-forn, jew għodod taħt sħana intensa, dan il-lift jiżgura operazzjoni sikura, stabbli u kontinwa.

| Parametru | Dettalji |

| Kapaċità ta' Tħaffir | ≤ 5T / > 5T (customizable) |

| Klassi tad-dazju | M6 (frequent operation, heavy-duty) |

| Għoli tal-irħiħ | Iddisinjati apposta għal kull rekwiżit tas-sit |

| Veloċità tal-irlift | Għażliet ta' veloċità waħda jew doppja |

| Sistema tal-brejkijiet | Operational + Safety (dual brake) |

| Protezzjoni Termika | Ħarsien ta' insulazzjoni b'temperatura għolja |

| Provvista tal-Enerġija | AC ta' 3 fażi, vultaġġ li jista' jiġi personalizzat |

| Għażliet ta' kontroll | Kontroll tal-pendenti / Remot mingħajr fili |

| Bażi tad-Disinn | CD/MD-type structure + custom upgrades |

| Konformità | GB, ISO, CE standards (export-ready) |

Imla l-formola hawn taħt biex tikseb aċċess immedjat għall-katalogu tal-krejn u tkellem mat-tim tekniku tagħna għal rakkomandazzjonijiet mill-ġdid