Krejn ta' fuq b'trab doppju FEM

Krejn ta' fuq b'trab doppju FEM

Prestazzjoni fuq xogħol tqal. Maniġġjar ta' preċiżjoni. Mibnija għall-applikazzjonijiet industrijali l-aktar esiġenti.

Ħarsa ġenerali

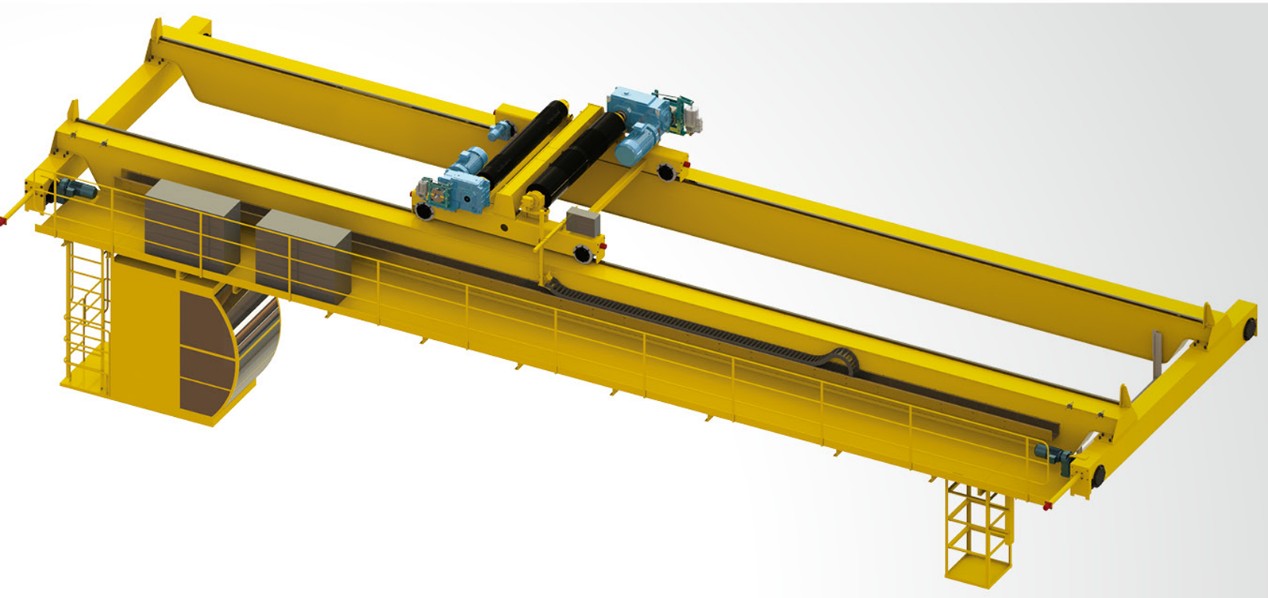

Il-krejn ta' fuq b'travi doppji standard FEM tal-Minjiera ta' Henan huwa soluzzjoni ta' irfija ta' xogħol tqal iddisinjata għal applikazzjonijiet ta' prestazzjoni għolja. Din is-sistema tal-krejn, maħsuba f'konformità mal-istandards Ewropej tal-FEM, tipprovdi durabbiltà, sigurtà u preċiżjoni eċċezzjonali tal-irfija f'firxa wiesgħa ta' industriji.

Ideali għall-impjanti tal-azzar, workshops ta' tagħmir tqal, ċentri loġistiċi, maħżen, u linji ta' pproċessar, il-krejn tal-Minjieri ta' Henan jinbnew b'komponenti ta' kwalità għolja, sistemi ta' sewqan intelliġenti, u strutturi modulari biex jissodisfaw il-ħtiġijiet esiġenti tal-klijenti

Kemm jekk għandek bżonn irlift ta' kapaċità għolja, effiċjenza fl-enerġija, jew inġinerija personalizzata, dan il-krejn joffri t-taħlita ideali ta' saħħa u versatilità.

| Parametru | Speċifikazzjoni |

| Marka | Minjiera Henan |

| It-tip | Double Girder Overhead Crane (FEM Standard) |

| Kapaċità ta' Tħaffir | 5 – 500 tunnellata |

| Spanja | Sa 35 metru |

| Veloċità tal-irlift | 5 / 0.38 m/min (customizable) |

| Veloċità tal-Ivvjaġġar | 0 – 40 m/min |

| Veloċità tal-Ivvjaġġar Cross | 0 – 100 m/min (VVVF control) |

| Klassi tax-Xogħol | M3 – M6 (medium to heavy duty) |

| Ċertifikazzjonijiet | CE / ISO / FEM |

Imla l-formola hawn taħt biex tikseb aċċess immedjat għall-katalogu tal-krejn u tkellem mat-tim tekniku tagħna għal rakkomandazzjonijiet mill-ġdid