- How to choose a customised portal crane

-

Release Time:2025-09-22 16:54:25Share:

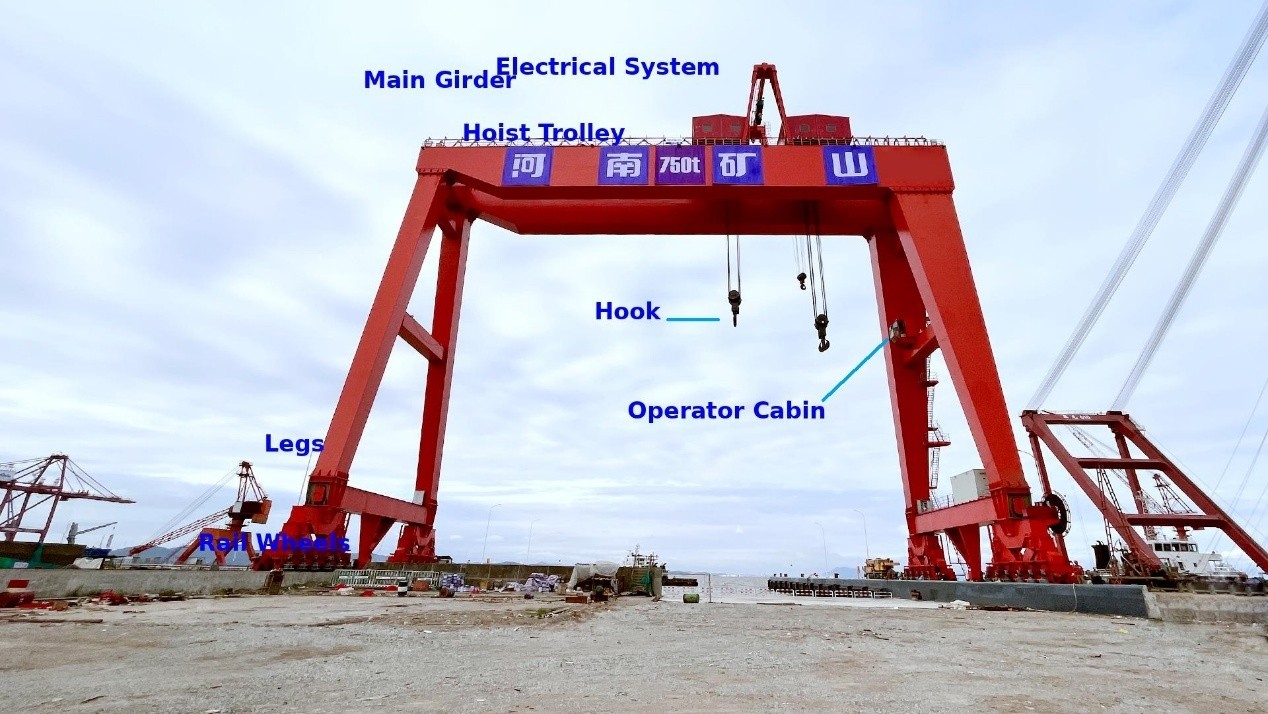

The selection of customised gantry cranes requires a comprehensive approach based on specific operational requirements, such as lifting capacity, span and working environment. The following dimensions must be considered primarily

1. Core parameter selection

Lifting capacity and span

Single-girder models are suitable for small-scale operations of up to 50 tons with spans of up to 35 metres, while double-girder models are designed for large-scale applications of over 200 tons with spans of over 100 metres.

Actual operations require verification of load distribution at lifting points to ensure that the rated capacity, including lifting gear, meets requirements.

2. Work environment adaptation

Rail-mounted cranes are suited to fixed track scenarios (e.g. ports and freight yards), while tyre-mounted cranes are suited to trackless environments (e.g. construction sites).

Fully enclosed cabs are required in high-temperature and dusty environments, and anti-tipping devices are necessary for elevated operations.

Structural and Performance Optimisation

3. Main beam structure: Double main beams (box or truss) offer superior load-bearing capacity and stability and are suitable for large spans. Single main beams feature simpler construction and are more cost-effective, making them ideal for smaller tonnages.

Wheelbase design: It is typically set at 1/4 to 1/6 of the span length to ensure operational stability and allow clearance for cargo passage under outriggers (generally ≥0.5 metres).

4. Cost and maintenance:

Prioritise a modular design to reduce customisation costs while balancing equipment maintenance cycles and energy consumption.

Although hydraulic synchronisation technology enhances installation efficiency (e.g. compressing a 6,000-tonne crane assembly to 14 days), it requires consideration of equipment acquisition costs.

5. Safety and Standards

Ensure compliance with national standards such as GB/T 23723.5-2025 to guarantee digital prototype validation and laser cutting precision (e.g. 9000 mm/min).

Allow for 10–15% lifting height redundancy to mitigate operational risks.