- Flagship Product: Gantry Crane

-

Release Time:2025-08-27 11:34:47Share:

>> Offset Electric Hoist Gantry Crane

The offset electric hoist gantry crane primarily consists of a gantry frame (main girder, outriggers, lower crossbeam, etc.), hoisting mechanism, traveling mechanism, and electrical control system. It employs an electric hoist as the hoisting mechanism, which travels along the lower flange of the main girder's I-beam during operation. The legs and lower crossbeam form an L-shape, providing a large lifting space and strong span-crossing capability, facilitating the transfer of objects from within the span to beneath the cantilever. It is suitable for general loading, unloading, and lifting operations in outdoor locations such as factories, mines, cargo yards, and warehouses within the small to medium load capacity range. Three operating modes are available: ground handle, wireless remote control, and operator cab. Power supply options include cable reels and overhead conductor rails.

>>Electric Hoist Semi-Gantry Crane

The electric hoist semi-gantry crane is a rail-mounted small-to-medium lifting device primarily composed of a gantry frame (main girder, outriggers, lower crossbeam, etc.), hoisting mechanism, travel mechanism, and electrical control system. It employs an electric hoist as the lifting mechanism, operating along the lower flange of the main girder's I-beam. One side of the gantry features outriggers for ground rail travel, while the opposite side lacks outriggers and runs on overhead factory tracks. Other structural configurations align with the MH-type electric hoist gantry crane.

>>Electric Hoist Truss Gantry Crane

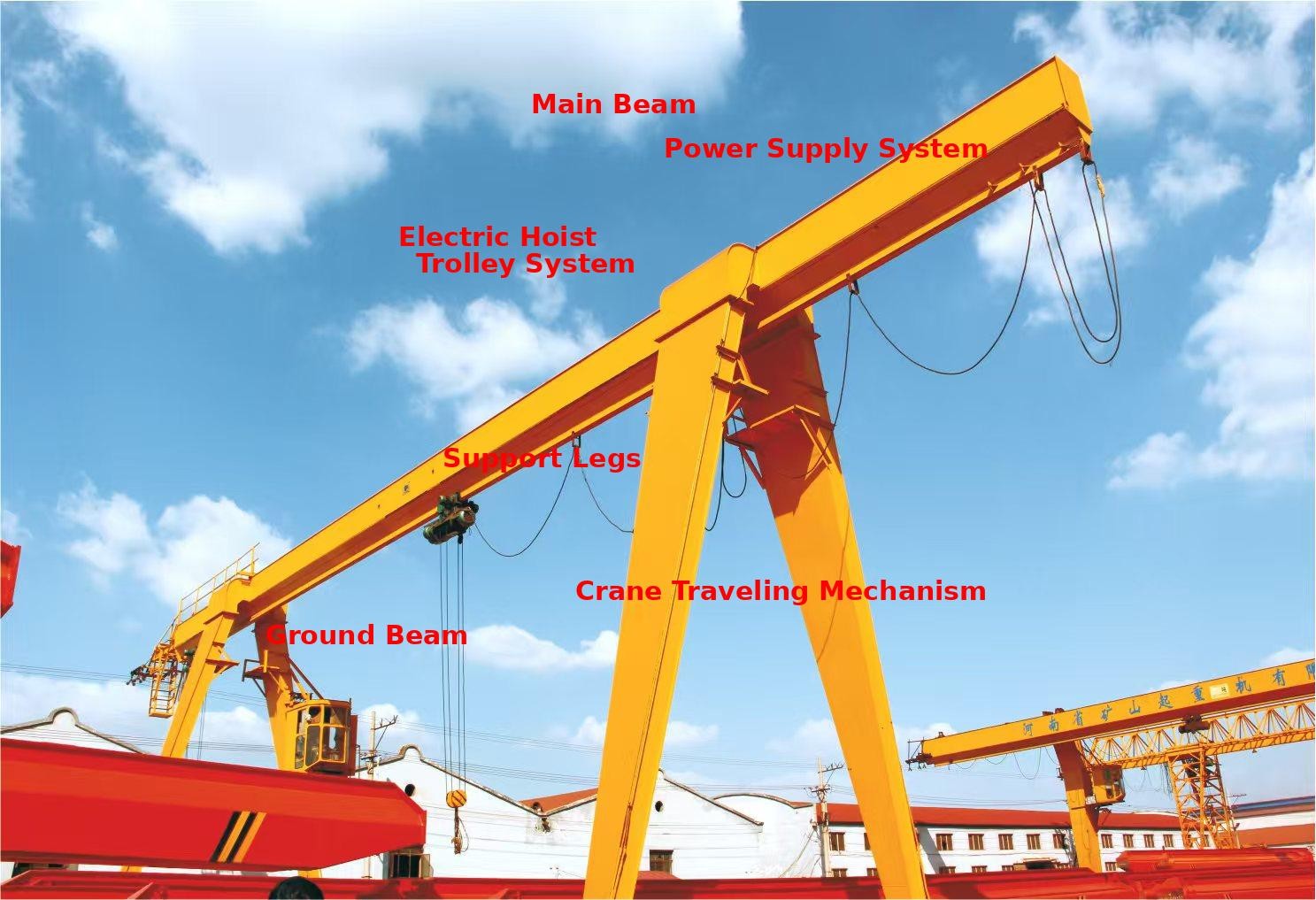

The electric hoist gantry crane is a small-to-medium-sized rail-mounted lifting device. It primarily consists of a gantry frame (main beam, outriggers, lower crossbeam, etc.), hoisting mechanism, traveling mechanism, and electrical control system. An electric hoist serves as the hoisting mechanism, operating along the lower flange of the main beam's I-beam during operation. The gantry structure comes in box-type and truss-type variants. The box-type offers superior workmanship and ease of fabrication, while the truss-type features lighter weight and enhanced wind resistance. The entire machine boasts characteristics such as light weight, simple structure, and convenient installation/maintenance. It is suitable for general loading, unloading, and hoisting operations in outdoor settings like factories, mines, cargo yards, and warehouses within the small to medium lifting capacity range.

>>Electric Hoist Box-Type Gantry Crane

The electric hoist gantry crane is a rail-mounted small-to-medium lifting device primarily composed of a gantry (main girder, legs, lower crossbeam, etc.), hoisting mechanism, traveling mechanism, and electrical control system. It employs an electric hoist as the lifting mechanism, operating along the lower flange of the main girder's I-beam. The gantry structure comes in two types: box-type and truss-type. The box-type offers superior workmanship and ease of fabrication; while truss types feature lighter weight and superior wind resistance. The entire machine boasts characteristics such as light weight, simple structure, and convenient installation/maintenance. It is suitable for general loading, unloading, and hoisting operations in outdoor settings like factories, mines, freight yards, and warehouses within the small to medium lifting capacity range.

>>Rail-mounted Container Gantry Crane

This crane is specifically designed for loading, unloading, and stacking 20-, 40-, and 45-foot international standard containers in railway freight yards. Equipped with a telescopic container spreader, it handles containers of various sizes. The spreader's locking/unlocking and telescoping operations are controlled by the operator from the cab. Additionally, to accommodate different container stacking orientations and container trailer travel directions, the spreader can incorporate a rotation mechanism, enabling arbitrary container rotation to enhance loading/unloading efficiency.

>>Single-Girder Gantry Crane

The single-girder gantry crane primarily consists of a gantry frame, hoist trolley, trolley travel mechanism, operator cab, and electrical control system. The gantry frame adopts a box-type single-girder with two legs. For lifting capacities below 20 tons, the trolley employs a vertical counter-rolling wheel design; for capacities above 20 tons, a horizontal counter-rolling wheel design is used, running along one side of the main girder. The main girder adopts a single-girder offset rail configuration. The legs and lower crossbeam form an L-shape, with cantilevers typically extending from both sides of the legs. This design provides strong span-crossing capability during material handling, facilitating the transfer of objects from within the span to beneath the cantilevers.

>>Double-girder Semi-Gantry Crane

The structural form is essentially the same as the MG crane. One side has a support leg and runs on ground rails; the other side has no support leg and runs on rails mounted on the upper part of the factory building.

>>Double-girder Truss Gantry Crane

This gantry crane is primarily used in bridge construction and operates at a slow speed. It consists of a gantry frame, hoist trolley, trolley travel mechanism, operator cab, and electrical control system. The gantry features a truss structure, offering advantages such as lightweight construction and strong wind resistance. Components include the main girder, upper end girder, outriggers, lower end girder, traveling trolley, and trolley guardrails. The main girder employs a triangular truss structure with rails laid on top, enabling the trolley to move laterally along the main girder. Outriggers are available in either box-type or steel pipe configurations. The trolley houses a compact, lightweight hoist.