- Henani kaevanduse väliskaubanduse tootmise eeliste ja müügijärgse teeninduse käsiraamat

-

Vabastusaeg:2025-07-09 21:30:34Jaga:

Henani kaevanduse väliskaubanduse tootmise eeliste ja müügijärgse teeninduse käsiraamat (siseversioon)

——Põhilise konkurentsivõime selgitus ülemaailmsetele partneritele

Tööstusharu liidrina, kellel on 23 aastat kraanamasinate tööstuses sügavat kasvatamist, on Henani kaevandus alati olnud pühendunud missioonile "muuta ülemaailmne logistika tõhusamaks". Tuginedes oma intelligentsele tootmissüsteemile ja kogu elutsükli teenindusvõrgule, pakub see kulutõhusaid "Made in China" lahendusi klientidele 122 riigis üle maailma. Järgnevalt on toodud põhiväited, mis aitavad teil rahvusvahelise turuga tutvuda:

I. Tootmise eelised: Hardcore intelligentne tootmine, iga seade "kaevandusallika" kvaliteediga

1. Aasia suurim intelligentne töökoda, robotid keevitavad "nulldefektidega"

Meie 169 000 ㎡ intelligentne nr 4 töökoda on varustatud üle 600 keevitusrobotiga. See kasutab laserskaneerimise + kaare jälgimise tehnoloogiat, mille keevisõmbluse täpsus ulatub millimeetri tasemeni. Ühe 5t - 22,5m standardkraana keevitusefektiivsus on kasvanud 30% ja valmistoote kvalifitseerimise määr on 99,9%. Nii nagu Baowu Shaogangi jaoks kohandatud mehitamata haaratsikraana, võib see robotite täieliku protsessi kaudu töötada pidevalt ja stabiilselt 24 tundi, aidates kliendil saavutada terase valmistamise ühe klõpsuga.

2,12 000 tonni sepistamisprotsess, ratta eluiga on üle kahe korra pikem kui tööstusharul

Loobudes traditsioonilisest valamisest, võtame kasutusele ümmarguse terasest kuumsepistamisprotsessi (moodustatud 12 000-tonnise pressiga). Ratta sisemine struktuur on kompaktsem ja selle kulumiskindlus on suurenenud 200%. Ühe rattakomplekti eluiga ületab 10 aastat. 2024. aastal on selle protsessiga Vietnami Yishan Iron and Steelile eksporditud 320-tonnine valukraana töötanud pidevalt 18 kuud ilma tõrgeteta kõrge temperatuuriga ja tolmuses keskkonnas.

3. Paindlik tootmisliin + modulaarne disain, 7-päevane tarne mittestandardse kohandamise jaoks

36 intelligentset paindlikku tootmisliini hõlmavad kogu põhitalade, otsatalade ja kärude protsessi, toetades "standardiseeritud moodulite + kohandatud funktsioonide" kiiret kombinatsiooni. Näiteks Indoneesia niklikaevanduse jaoks kohandatud plahvatuskindla pukk-kraana jaoks kulus kinnitusest tarnimiseni vaid 15 päeva, mis on 40% kiirem kui tööstusharu keskmine. 2023. aastal tarnisime ülemaailmsetele klientidele üle 800 mittestandardse seadme, mis hõlmasid enam kui 50 alamstsenaariumi, nagu tuumaelektrijaamad ja puhtad töökojad.

4. 128 000 ühiku suuruse aastatoodangu "tarnekindlus"

1,62 miljoni ㎡ tehasepinna ja enam kui 3,500 intelligentse seadmega on meie aastane tootmisvõimsus 128 000 ühikut (komplekti), mis võrdub 350 kraanaga, mis iga päev tootmisliinilt maha tulevad. 2024. aasta esimesel poolel tarnisime "Siiditee projektidele" 21 pukk-kraanat. Tellimuse kättesaamisest kuni saatmiseni kulus vaid 28 päeva, tagades selliste võtmeprojektide edenemise nagu heitsoojusenergia tootmine Pakistanis ja kaevandustööstus Kongos.

II. Müügijärgne teenindus: 24-tunnine globaalne reageerimine, "murede" mõistmine paremini kui kliendid

1. Jõudke 1000 tunniga 24 kilomeetri raadiusesse, lokaliseeritud välisteenus

Maailmas (sealhulgas Kagu-Aasia, Lähis-Ida ja Euroopa) on 428 teeninduspunkti, mis on varustatud üle 1,200 sertifitseeritud inseneriga. Pärast remonditaotluse saamist saavad insenerid Hiinas 24 tunni jooksul 1000 kilomeetri raadiuses tehasesse jõuda ja peamistel välisturgudel (nt Indoneesia ja Vietnam) vastata 48 tunni jooksul. 2023. aastal kiirustasime üleöö Tai kliendile sadamakraanat parandama ja taastasime selle töö 18 tunniga, vältides kliendi igapäevast üle 500 000 dollari suurust kahju.

Vaba pööre - võtmeteenus: Niipea kui seadmed jõuavad tehasesse, saadetakse insenerid objektile, et pakkuda paigaldust, kasutuselevõttu, koormuse testimist ja operaatori koolitust (sealhulgas mitu keelt, näiteks inglise ja vene keelt).

Näiteks Iraani kliendile kohandatud pärsiakeelne kasutusjuhend tagab, et kohalikud töötajad saavad alustada 3 päevaga.Eluaegne varuosade tugi: Maailmas on 8 suurt varuosade ladu, kus hoitakse üle 5,000 üldosa ning mittestandardseid osi saab kohandada ja tarnida 72 tunni jooksul.

Vanade klientide jaoks käivitasime programmi "Vahetus". 2024. aastal uuendasime India kliendi jaoks 12 10 aastat vana seadet, säästes 40% kuludest.3. Kaugjuhtimise ja -hoolduse pilveplatvorm, mis paneb kraanad "rääkima"

Meie enda väljatöötatud IoT-süsteem suudab reaalajas jälgida enam kui 3,000 seadet kogu maailmas ja ennustada rikkeid 12 andmeelemendi kaudu, nagu vibratsioon ja temperatuur. 2025. aastal ennustasime Serbia vasetööstuse pukk-kraana jaoks ette ratta-telje, vältides seiskamisõnnetust. Selle tulemusena esitas klient lisatellimuse 20 ühikule.

4. "Lapsevagaduse kultuuri" geen, rohkem südantsoojendavat teenust

Asutaja hr Cui Peijun propageerib, et "teenindus on vastutus". Meie insenerid mitte ainult ei paranda seadmeid, vaid võtavad ka initsiatiivi klientide koolitamiseks ohutuks kasutamiseks. 2024. aastal viibisime 3 kuud Bangladeshis elektriprojekti objektil ning aitasime kliendil optimeerida ka töökoja paigutust, suurendades efektiivsust 15%. Klient saatis tänukirja, öeldes "hoolivam kui perekond".

Meil on Jakartas alaline meeskond. Eelmisel nädalal küsitud 10-tollist pukk-kraanat saab kohandada vastavalt Indoneesia riiklikule standardile SNI, tarnega 21 päeva. Meie müügijärgne vastus on isegi kiirem kui kohalikel tarnijatel!

Meie CE-sertifikaadiga kraanadel on Saksa TÜV poolt sertifitseeritud keevisõmblused ning kaugjuhtimis- ja hooldussüsteem on ühendatud Siemensi tööstuspilvega, tagades teie seadmete andmete turvalisuse.

2019. aastal ostetud 5 seadme puhul tuvastasime rataste kulumise hoiatuse ja saatsime uued osad tasuta. See on meie kohustus "eluaegsele teenistusele".

tootmine + sulgemine - paigaldusteenus". Väliskaubandusmeeskonnana ei müü me mitte ainult seadmeid, vaid müüme ka "Hiina tõhusust" – muutes iga "Mine Source" kraana mobiilseks varaks, mida kliendid usaldavad.

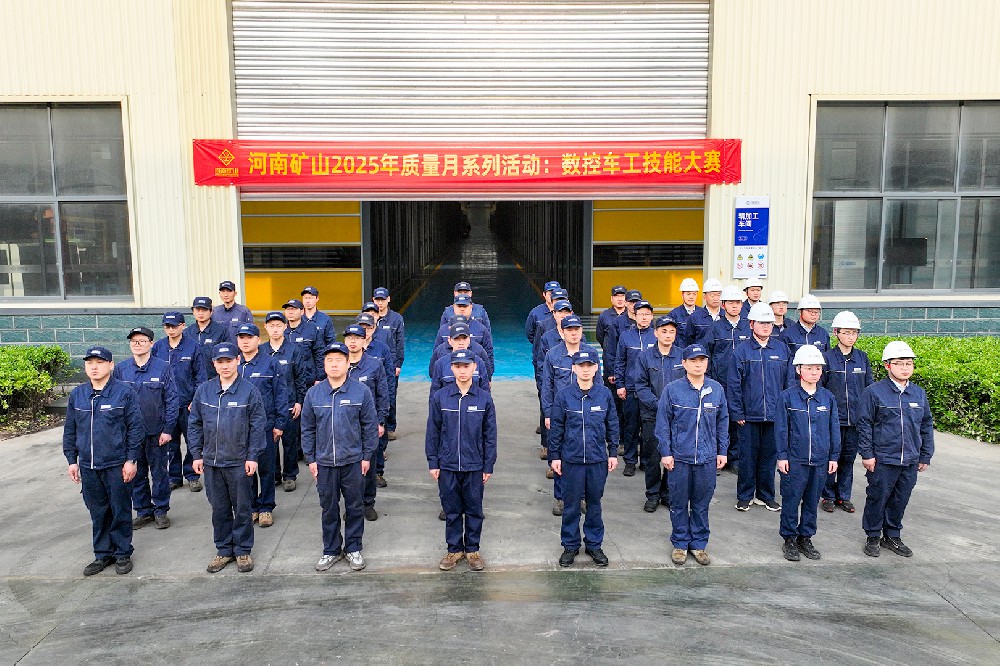

513车间-(2)(1).jpg